Hybrid power system and vehicle

A hybrid power system, No. 1 technology, which is applied in power units, vehicle components, pneumatic power units, etc., can solve problems such as power loss and other functional drive modes that are single, and the pure electric mode No. 2 motor cannot be adjusted in speed, so as to avoid The effect of No. 2 motor follow-up, improving power and economy, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

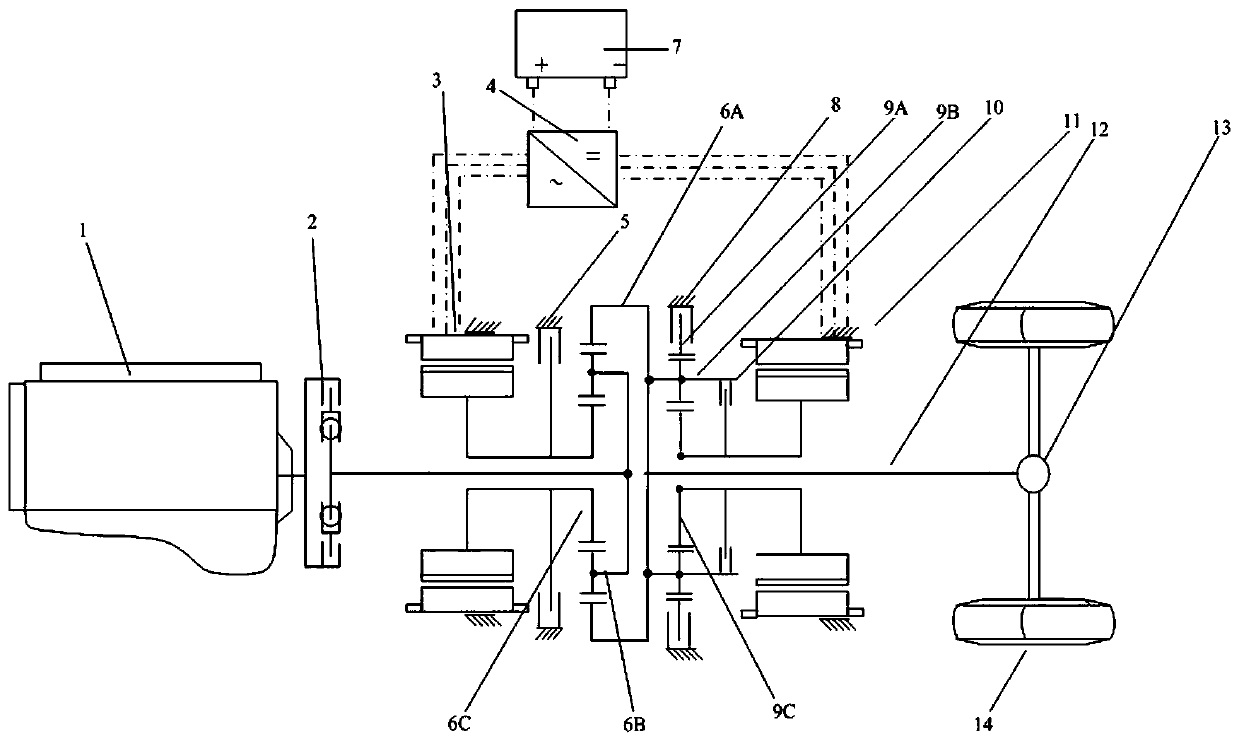

[0027] Embodiment 1 of the vehicle of the present invention: the vehicle includes a vehicle body and a hybrid system, such as figure 1 As shown, the hybrid system includes an engine 1, a torsional shock absorber 2, a No. 1 motor 3, a motor controller 4, a first brake (or clutch) 5, a first planetary ring gear 6A, and a first planetary planet carrier 6B. , the first planetary row sun gear 6C, the power supply 7, the second brake (or clutch) 8, the second planetary row ring gear 9A, the second planetary row carrier 9B, the second planetary row sun gear 9C, the first clutch 10 , No. two motor 11, output shaft 12, rear axle 13, tire 14. The output shaft of the engine 1 is connected with the first planetary planet carrier 6B through the torsional shock absorber 2; the rotor of the No. 1 motor 3 is connected with the first brake (or clutch) 5 and the first planetary sun gear 6C; the first The planetary gear ring gear 6A is connected with the second planetary planetary carrier 9B an...

Embodiment 2

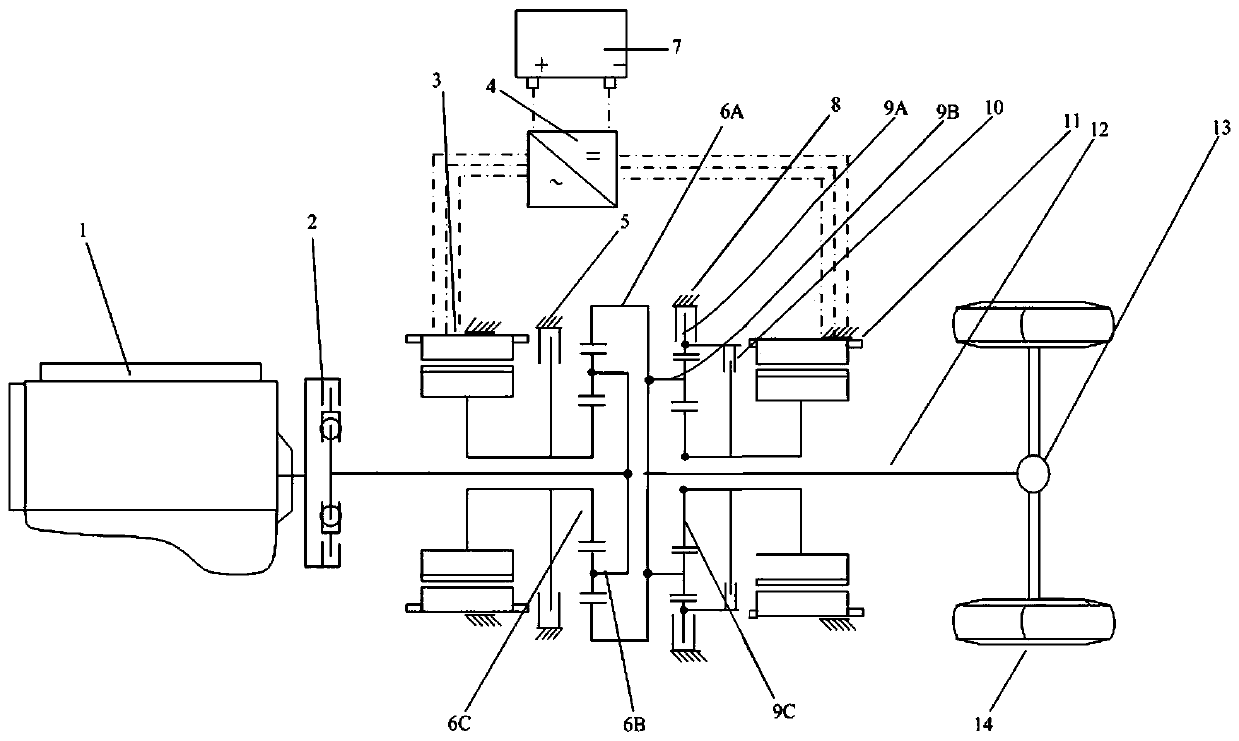

[0044] Embodiment 2: The difference with Embodiment 1 is that, as figure 2 As shown, one end of the first clutch 10 is connected to the second planetary gear ring gear 9A, and the other end is connected to the rotor of the second motor 11. Its working process is similar to that of Embodiment 1 and will not be repeated here.

Embodiment 3

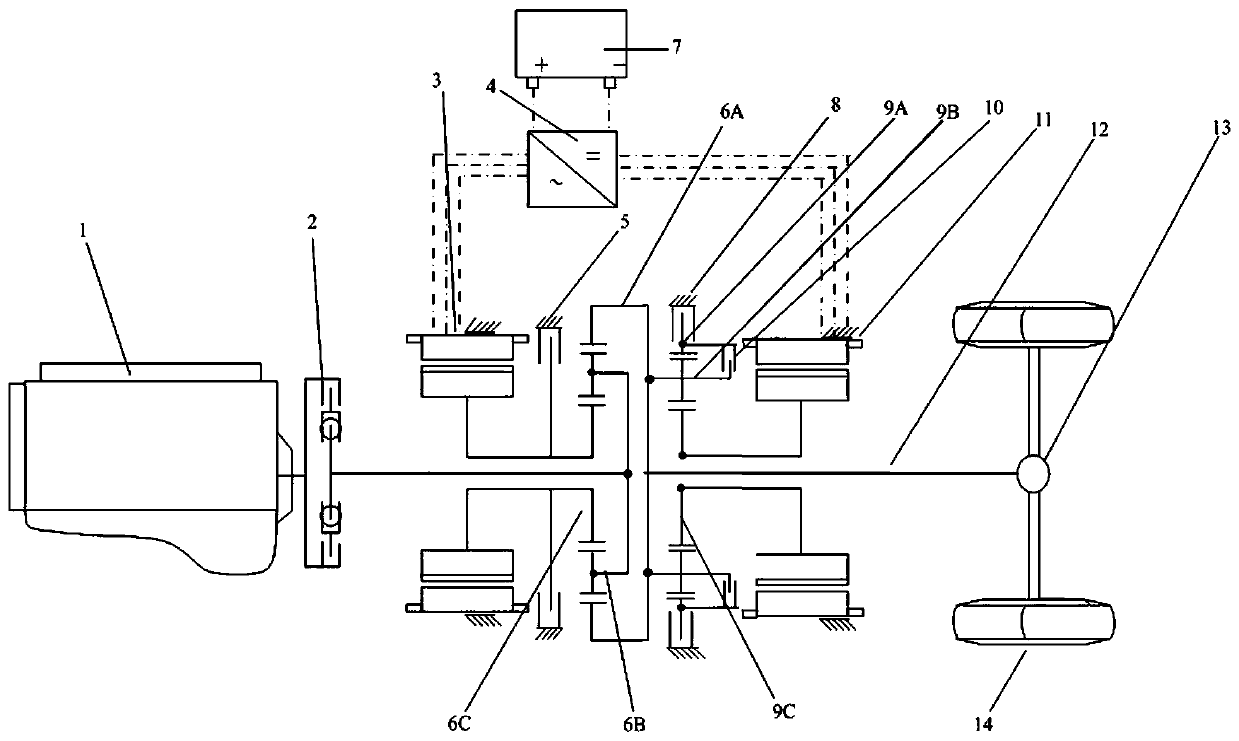

[0045] Embodiment 3: The difference with Embodiment 1 is that, as image 3 As shown, one end of the first clutch 10 is connected to the second planetary ring gear 9A, and the other end is connected to the second planetary carrier 9B. The working process of the first clutch 10 is similar to that of Embodiment 1, and will not be repeated here.

[0046] In other embodiments: the first and second brakes (or clutches) can also be replaced by other types of braking devices; the input and output components of the front planetary row can also be changed, for example, can be changed to utilize the planetary carrier for output.

[0047] The embodiments of the hybrid power system of the present invention are the same as the embodiments of the hybrid power system in the embodiments of the vehicle of the present invention, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com