A Modular Integrated Brake Performance Test Bench

A test bench and modular technology, applied in the direction of railway vehicle testing, etc., can solve problems such as single function, and achieve the effect of saving space, compact structure and optimized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

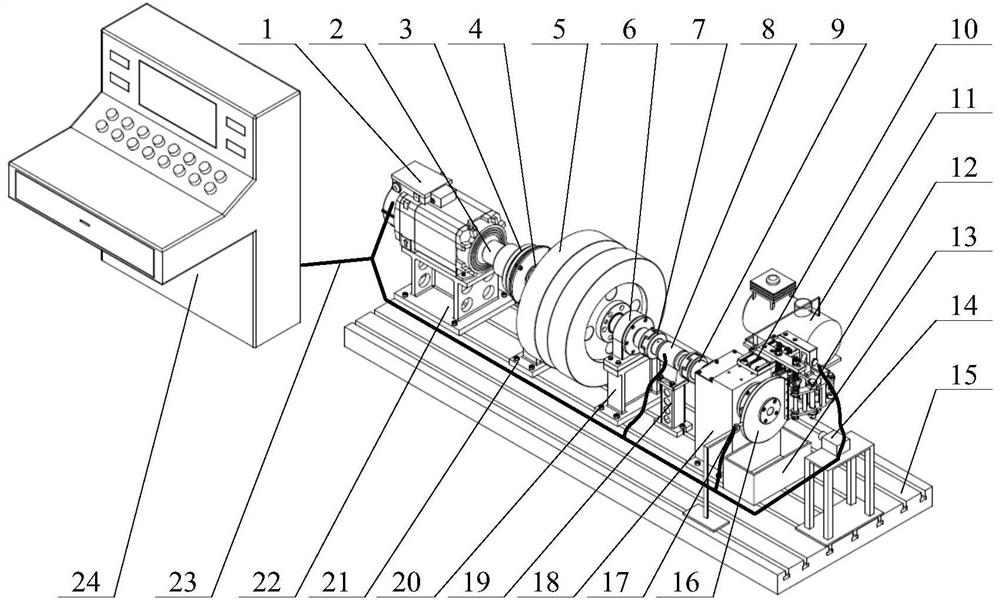

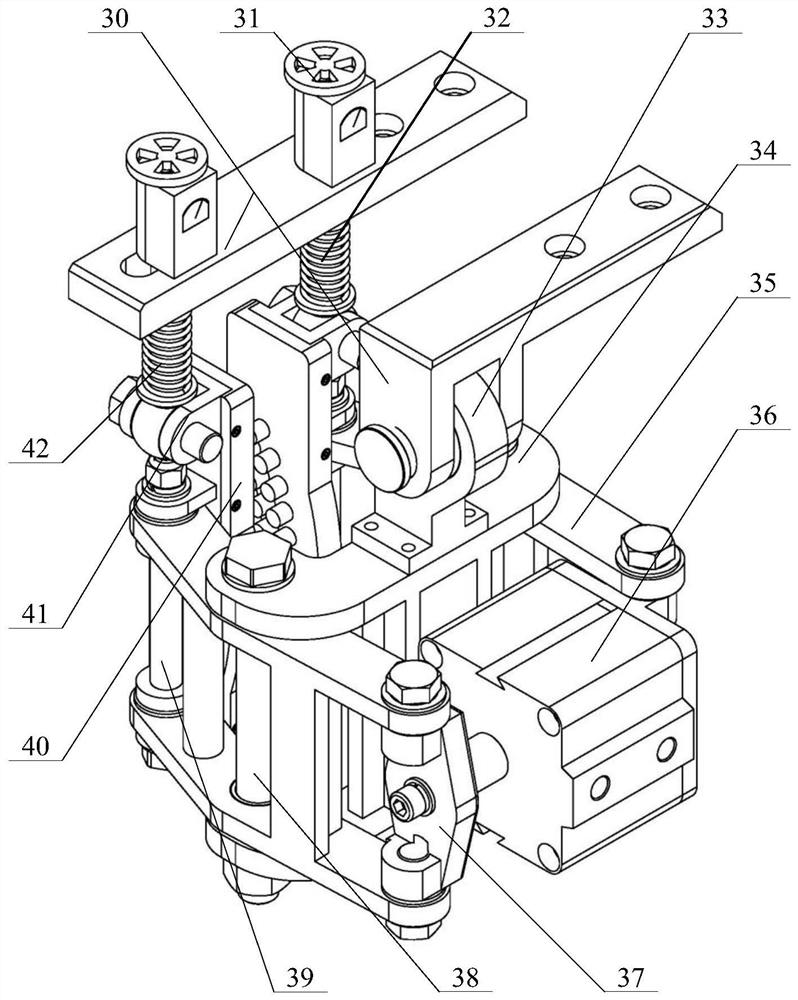

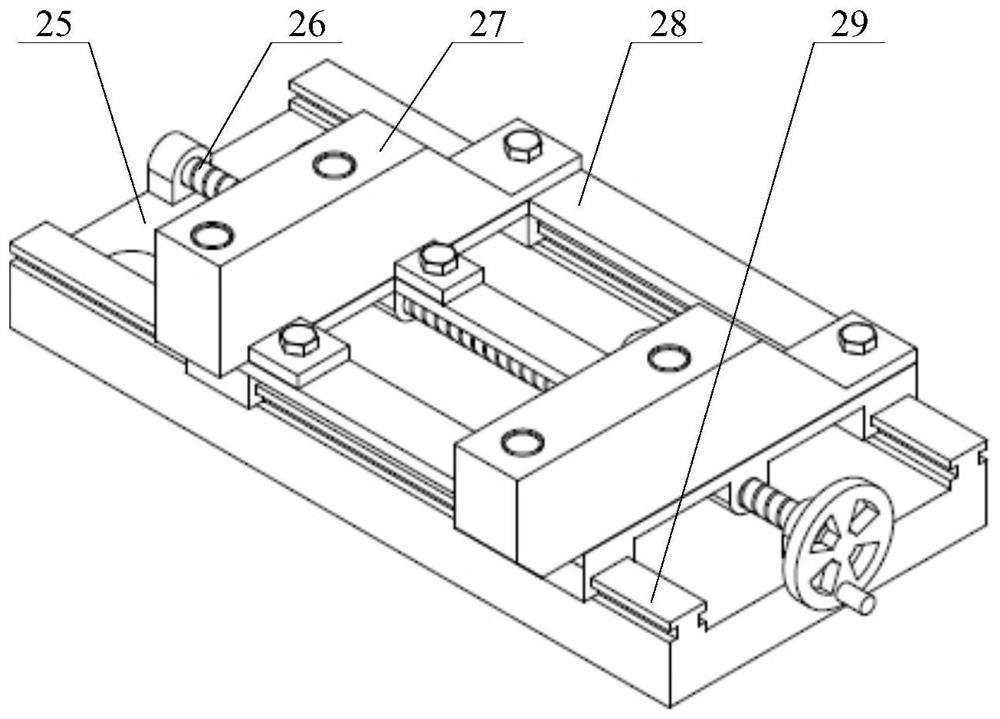

[0053] A modularized comprehensive braking performance test bench is installed in a laboratory. First, prefabricate a foundation of suitable size and depth in the laboratory, completely fix the test bench base 15 and the foundation, and install the brake module loading seat 18, torque sensor mounting table 19, bearing seat II mounting table 20, and bearing seat I through bolts. Table 21, motor installation table 22 are fixedly connected with test bench base 15, the output shaft of motor 1 is connected with clutch 3 through clutch motor coupling sleeve 2, power transmission is realized through bearing seat I4 and flywheel group 5, and flywheel group 5 supports Between the bearing seat I4 and the bearing seat II6, the output end of the rotating shaft of the flywheel group 5 is connected to the rotating shaft of the torque sensor 8 through the coupling I7. The disc I 16 is connected with a rotating shaft, and the rotating shaft is installed on the brake module loading seat 18 thr...

Embodiment 2

[0061] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the train disc caliper brake module is changed to a single friction block caliper brake module, and the single friction block caliper brake module includes a cylinder II48 and is used to connect with the brake module The support frame 46 connected to the loading seat 18, the support frame 46 is connected with a support arm 45, each of the two ends of the support arm 45 is hinged with a curved arm 47, and one end of the two curved arms 47 is connected to the cylinder II48 respectively. Both ends are hinged, and the other ends of the two curved arms 47 are respectively hinged with a friction block unit 44 for providing braking force to the side of the brake disc.

[0062] When carrying out the train braking performance test of a single friction block under different shapes, the single friction block caliper brake module assembled by the friction block unit 44, the support...

Embodiment 3

[0065] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the brake module of the train disc caliper is changed to a tread brake module, and the tread brake module includes a tread brake mounting seat 49 for connecting with the brake module loading seat 18 , the tread brake mount 49 is fixedly connected with a cylinder III51 and a tread slant support 50, the lower end of the tread slant support 50 is hinged with an intermediate rod 52, and the extension direction of the cylinder rod of the cylinder III 51 is vertically downward Set, the end of the cylinder rod is hinged with the middle rod 52, and the end of the middle rod 52 is connected with a tread brake friction block 53, and the tread oblique support 50 and the tread brake friction block 53 are respectively located on the sides of the cylinder rod. On both sides, the tread brake friction block 53 is located above the brake disc.

[0066] When carrying out the tread brake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com