Preparation method of tobacco filter capsule with slow release function

A functional and tobacco technology, applied in the field of tobacco, can solve problems such as the need to increase the rate of fragrance attachment, low particle strength, and concerns about the safety of small additives, and achieve the benefits of large-scale industrial production, refractory and high temperature post-processing fusion, excellent The effect of post-processing fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of tobacco incense beads with sustained release function, which comprises the following process steps:

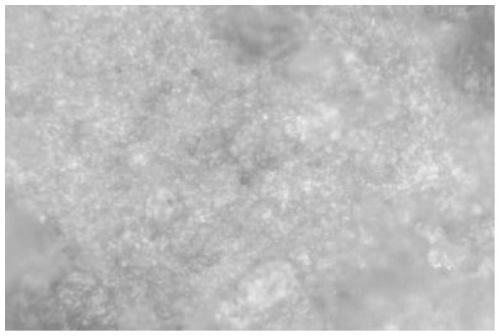

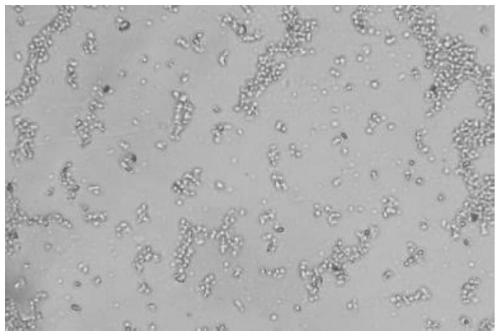

[0023] 1) Put 10 parts of konjac powder, 15 parts of white carbon black, 10 parts of licorice powder, 20 parts of chitin and 30 parts of distilled water in a double-roller dry granulator for one-time molding according to the weight of raw materials. granules to obtain dry, uniformly sized circular dry beads with a porous structure on the surface, the average pore diameter of the porous structure on the surface is 3 μm, and the diameter range of the dry beads is 2.9 mm;

[0024] 2) Put the fragrance-fixing moisturizer and the dry beads obtained in step 1) in a weight ratio of 3.5:1 and mix them uniformly at 50°C and stir for 2 hours, then air-dry at 50°C for 0.5h to obtain the finished product of Example 1 , and its fragrance rate is 38%.

[0025] Wherein, the fragrance-fixing moisturizer in step 2) of this embodiment is prepared by mixing 20 par...

Embodiment 2

[0027] A preparation method of tobacco incense beads with sustained release function, which comprises the following process steps:

[0028] 1) Put 20 parts of konjac powder, 10 parts of white carbon black, 15 parts of licorice powder, 10 parts of chitin and 40 parts of distilled water in a double-roller dry granulator for one-time molding according to the weight of raw materials. granules, to obtain dry, uniform-sized round dry beads with a porous structure on the surface, the average pore diameter of the porous structure on the surface is 8 μm, and the diameter range of the dry beads is 2.5 mm;

[0029] 2) Put the fragrance-fixing moisturizer and the dry beads obtained in step 1) in a weight ratio of 5:1, mix them uniformly at 40°C and stir for 3 hours, then air-dry at 40°C for 1.5 hours to obtain the finished product of Example 2 , and its incense rate is 45%.

[0030] Wherein, the fragrance-fixing moisturizer in step 2) of this embodiment is prepared by mixing 50 parts of ...

Embodiment 3

[0032] A preparation method of tobacco incense beads with sustained release function, which comprises the following process steps:

[0033] 1) Put 10 parts of konjac powder, 15 parts of white carbon black, 12 parts of licorice powder, 20 parts of chitin and 35 parts of distilled water in a double-roller dry granulator for one-time molding according to the weight of raw materials. granules, to obtain dry, uniform-sized round dry beads with a porous structure on the surface, the average pore diameter of the porous structure on the surface is 4 μm, and the diameter range of the dry beads is 2.5 mm;

[0034] 2) Put the fragrance-fixing moisturizer and the dry beads obtained in step 1) in a weight ratio of 3.5:1 and mix them uniformly at 50°C and stir for 2 hours, then air-dry at 50°C for 0.5h to obtain the finished product of Example 3 , and its incense rate is 40%.

[0035] Wherein, the fragrance-fixing moisturizer in the step 2) consists of a mixture of 20 parts of water-solubl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com