Environment-friendly solid garbage treatment equipment

A technology for solid waste and processing equipment, applied in grain processing, solid waste removal, etc., can solve problems such as low pulverization efficiency, achieve the effect of convenient collection and avoid dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

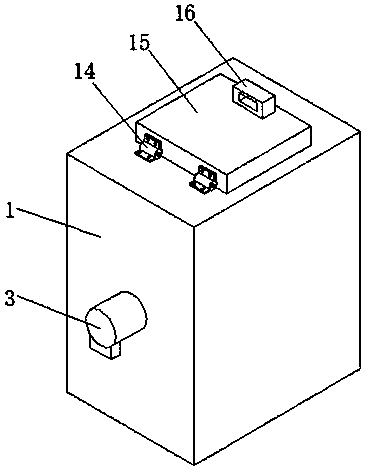

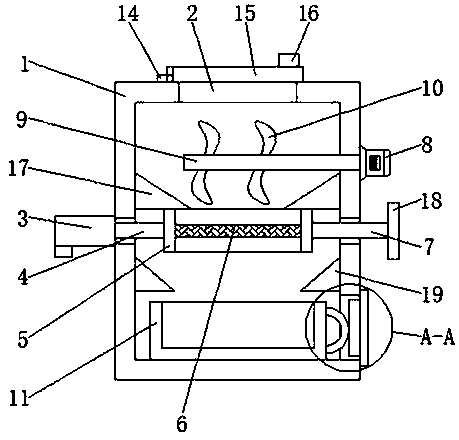

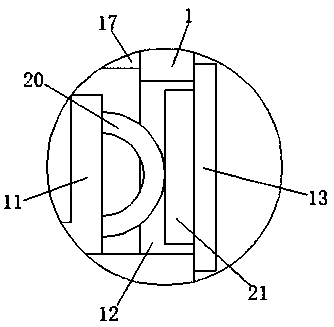

[0023] First implementation: see Figure 1-4 , an environment-friendly solid waste treatment equipment, comprising a housing 1, the top of the housing 1 is provided with a feeding port 2, the top of the housing 1 and the position corresponding to the feeding port 2 are movably connected with a cover plate 15 through a hinge 14, through Setting the cover plate 15 can close the device to avoid dust pollution caused by the device during work. The right side of the top of the cover plate 15 is fixedly connected with an operating handle 16. By setting the operating handle 16, the staff can operate the cover plate 15. More convenient, the electric push rod 3 is fixedly connected to the midpoint on the left side of the housing 1, and the power rod 4 is fixedly connected to the output end of the electric push rod 3, and the right side of the power rod 4 runs through the housing 1 and extends to its interior for fixing. The shaking frame 5 is connected, and the left and right sides of ...

no. 2 approach

[0026] The second embodiment: as shown in claim 1, an environment-friendly solid waste treatment equipment includes a casing 1, the top of the casing 1 is provided with a feeding port 2, and the middle point on the left side of the casing 1 is The electric push rod 3 is fixedly connected to the output end of the electric push rod 3, and a power rod 4 is fixedly connected to the output end of the electric push rod 3. The right side of the power rod 4 runs through the housing 1 and extends to its interior to be fixedly connected to a shaking frame 5, so The left and right sides of the inner wall of the housing 1 and the position corresponding to the shaking frame 5 are fixedly connected with a material guide plate 17, the inner wall of the shaking frame 5 is fixedly connected with a screen 6, and the right side of the shaking frame 5 is fixedly connected with a Connecting rod 7, the right side of the connecting rod 7 runs through the housing 1 and extends to the outside, the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com