Power control device for low-power laser device and control method thereof

A power control and laser technology, applied in the field of lasers, can solve problems such as inapplicability and damage to objects, and achieve the effects of convenient control, increased service life, and reduced corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

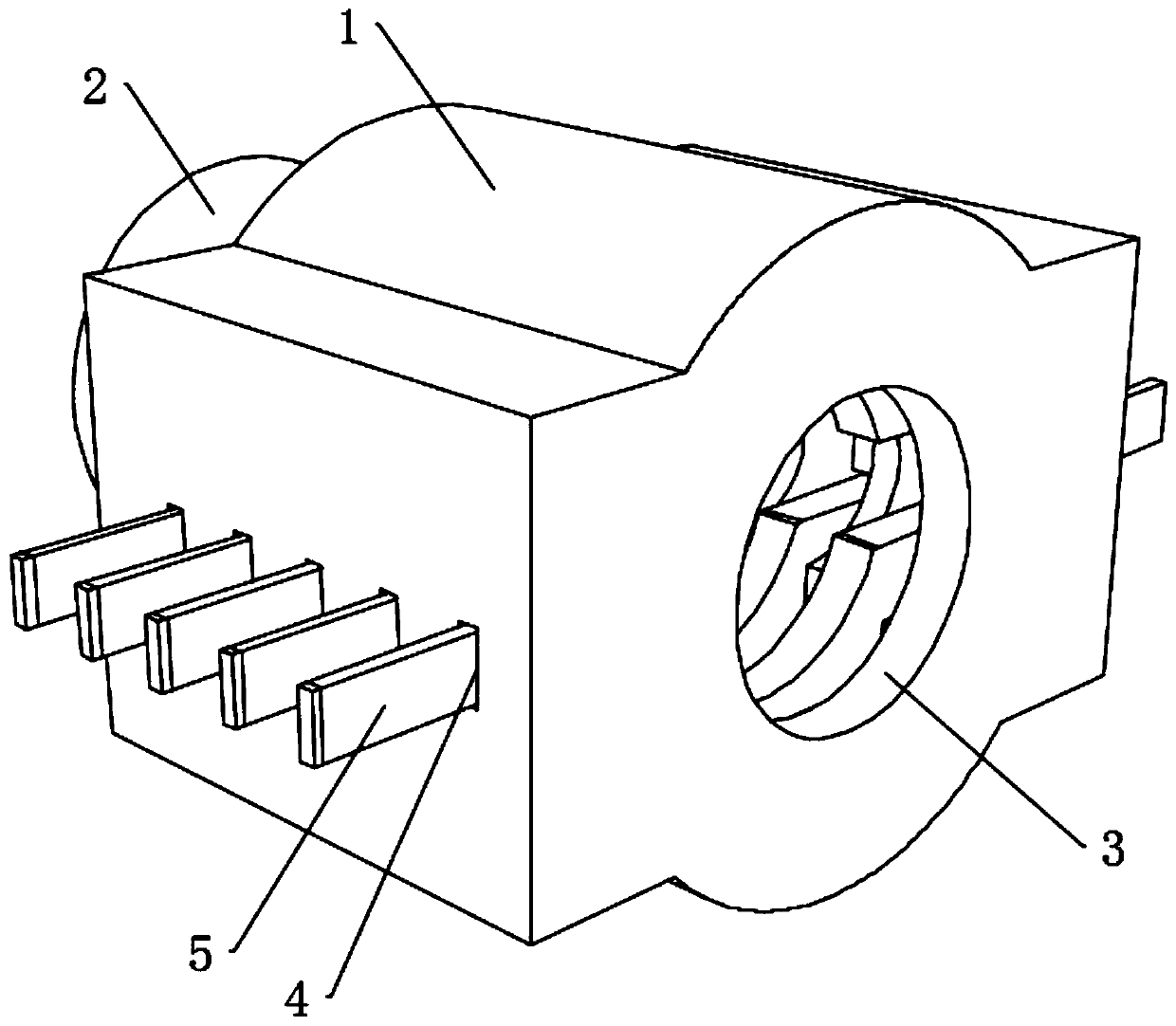

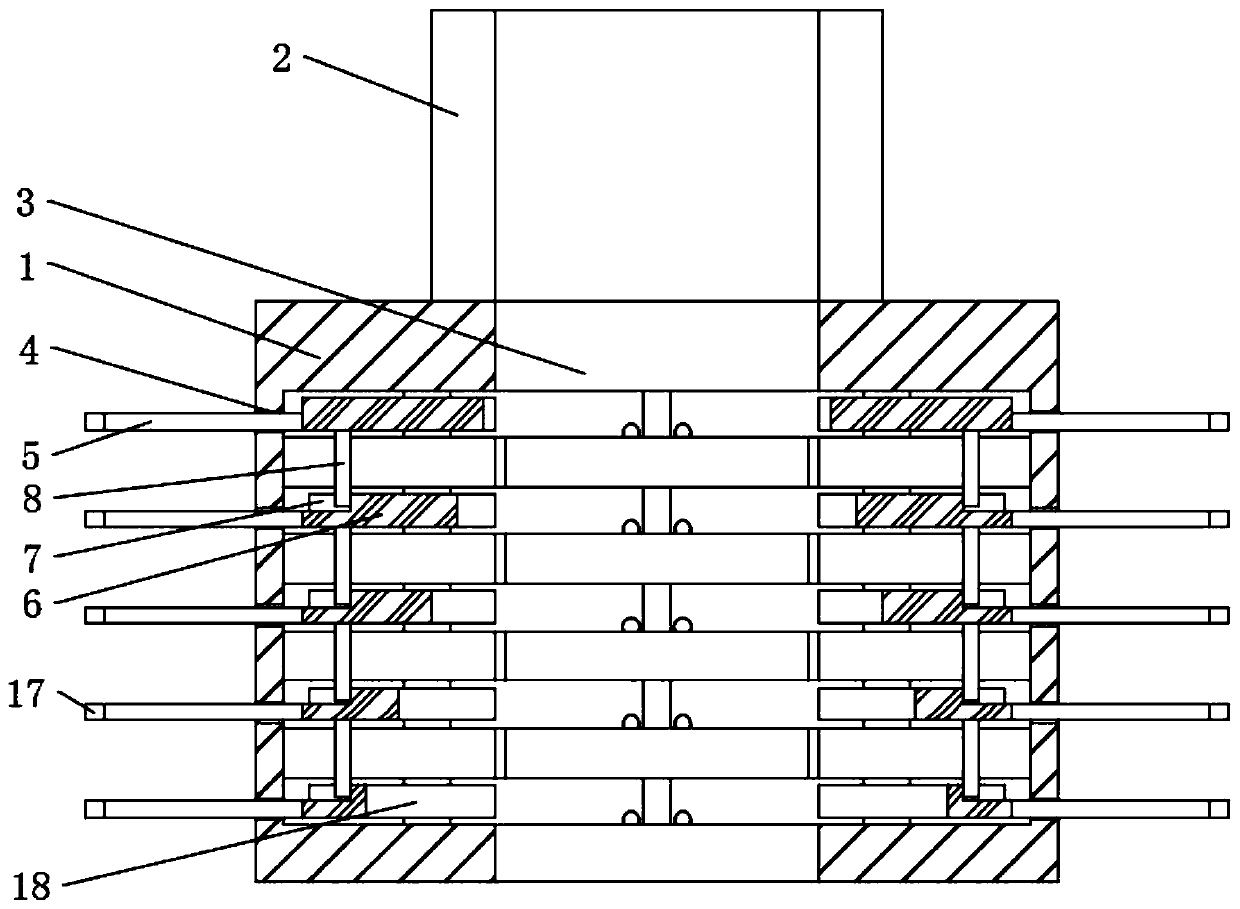

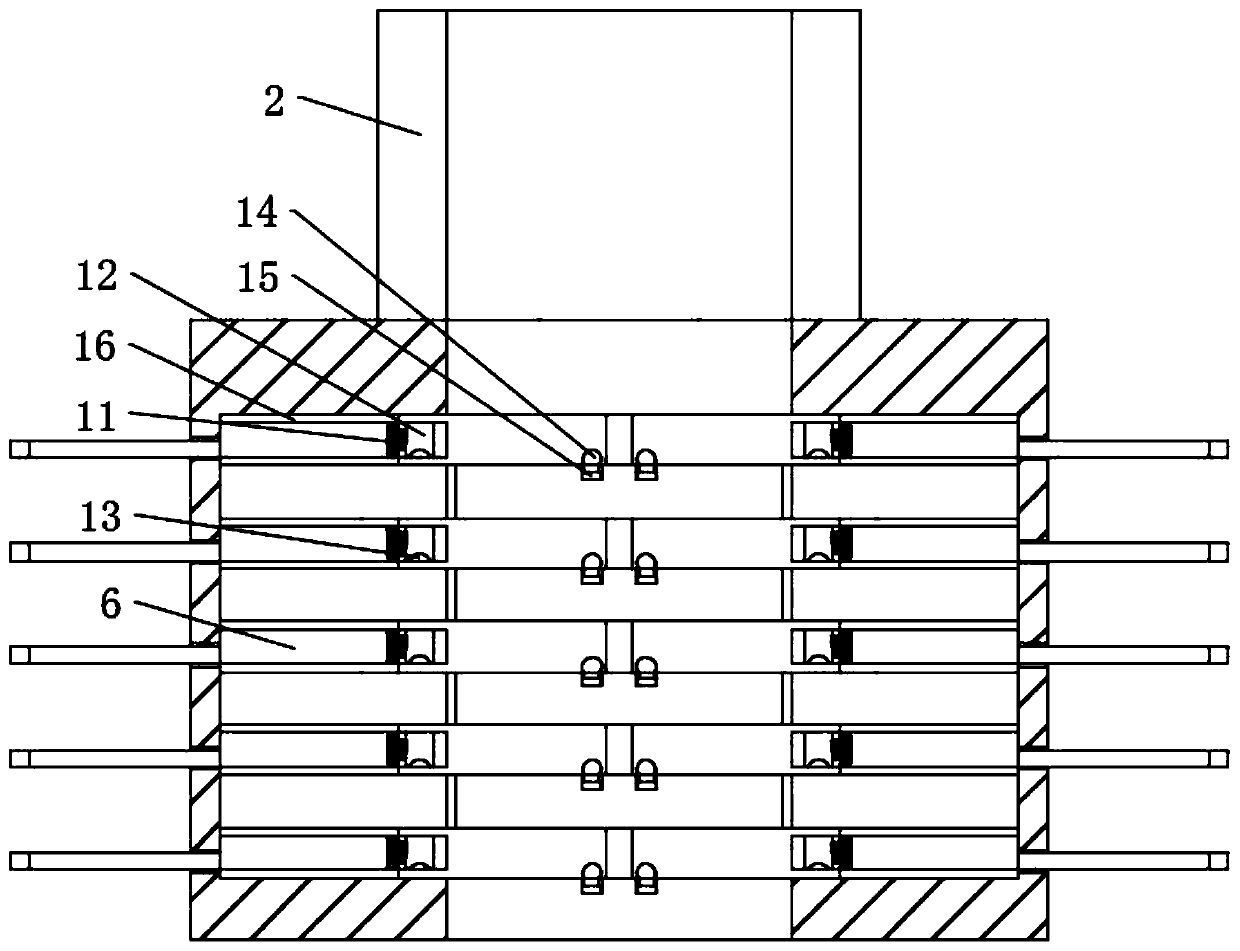

[0048] A kind of laser power control device and method thereof for low power application, please refer to figure 1 , including a laser control lens 1, the rear end of the laser control lens 1 is fixedly connected with a laser guide 2, and the outer end of the laser guide 2 is fixedly connected with a laser emitter, and the laser emitter emits laser light into the laser guide 2, so that the laser passes through The laser guide 2 and the laser control lens 1 act on the outer end of the object, so that the laser can act on the object. There are a plurality of sliding holes 4 drilled at the left and right ends of the laser control lens 1. Please refer to Figure 2-3 , the walls of the left and right ends of the guide groove 3 are dug with a plurality of chutes 16, and the left and right ends of the plurality of chutes 16 are slidably connected with a laser diameter control block 6, and the laser diameter control blocks 6 at the left and right ends are all dug with a semi-arc shape....

Embodiment 2

[0052] The present invention is in the operation step to the power control of low-power laser:

[0053] Step 1. Connect the laser guide 2 with the laser emitter, and turn on the current detector, power controller, power supply and laser emitter respectively, so that the laser emitter can emit the laser beam.

[0054] Step 2: The staff adjusts the diameter of the laser beam according to the power of the laser beam required to act on the object.

[0055] Step 3, please refer to image 3 , the staff will move the adjustment block 5 to the end close to the guide groove 3, and drive the laser diameter control block 6 to move to the end close to the guide groove 3. Under the mutual cooperation between the groove 13 and the hemispherical block 14, the laser diameter The position of the control block 6 is fixed so that the laser diameter control block 6 blocks the laser beam emitted by the laser emitter.

[0056] Step 4: The staff acts on the object with the laser beam after the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com