Automatic welding manipulator for automobile assembly

An automatic welding and automobile assembly technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems that affect welding efficiency and cannot weld from multiple angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

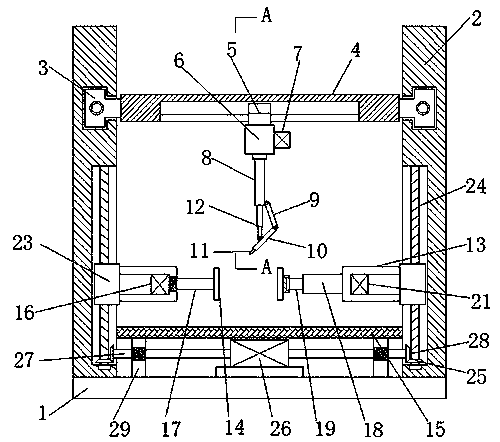

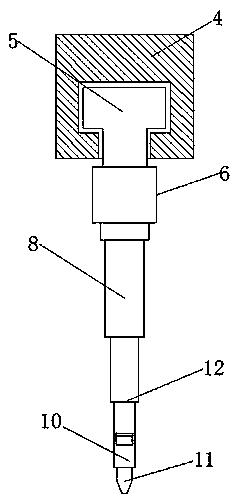

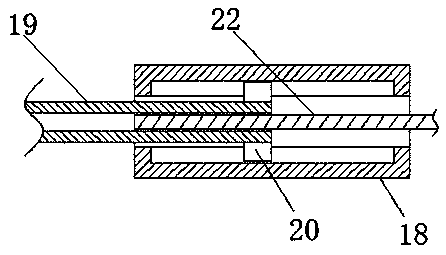

[0023] see Figure 1-4 , an automatic welding manipulator for automobile assembly, comprising a base 1 and support plates 2 arranged on both sides of the upper end of the base 1, the two support plates 2 are arranged symmetrically, and the upper ends of the two opposite side walls of the two support plates 2 are provided with longitudinal Slide rails, the inside of the two longitudinal slide rails are slidably connected with longitudinal sliders 3, before the two support plates 2 there is a horizontal beam 4, the two ends of the beam 4 are respectively fixedly connected with the two longitudinal sliders 3, the beams The lower end of 4 is provided with transverse slide rail, and the interior of transverse slide rail is slidably connected with transverse slide block 5, and the lower end of transverse slide block 5 is fixedly connected with reduction box 6, and one side of reduction box 6 is fixedly connected with drive motor 7, and drive motor The output shaft of 7 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com