Disassembling and assembling method for oversized connecting bolt of high pressure container

A technology for connecting bolts and high-pressure vessels, which is applied in the field of disassembly and assembly of super-large connecting bolts of high-pressure vessels, which can solve the problems of large-diameter bolt fastening, difficult disassembly, low work efficiency affecting the construction period, and impossibility of dismantling due to impact force, so as to achieve low maintenance costs and avoid Explosion accident, labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

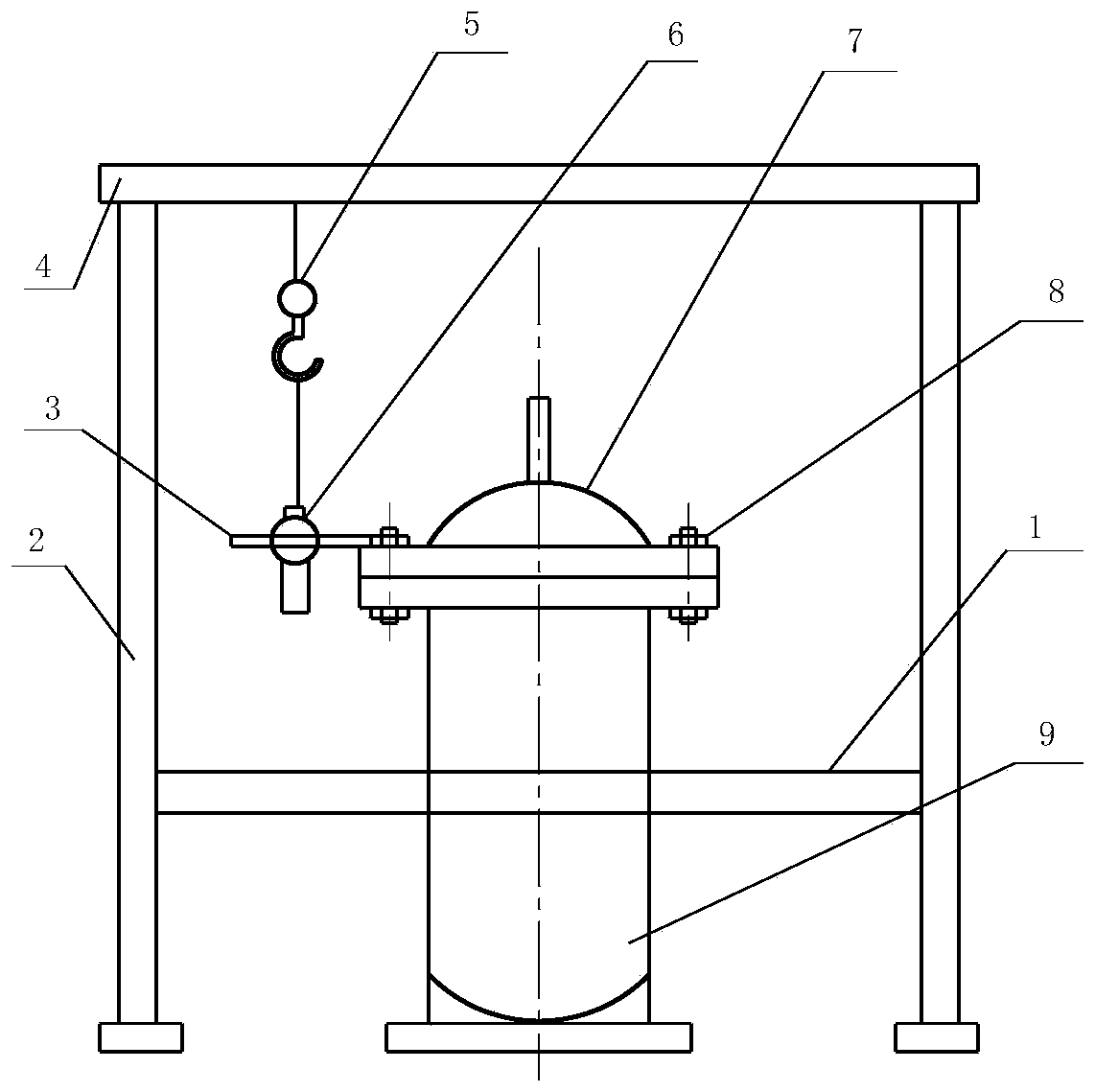

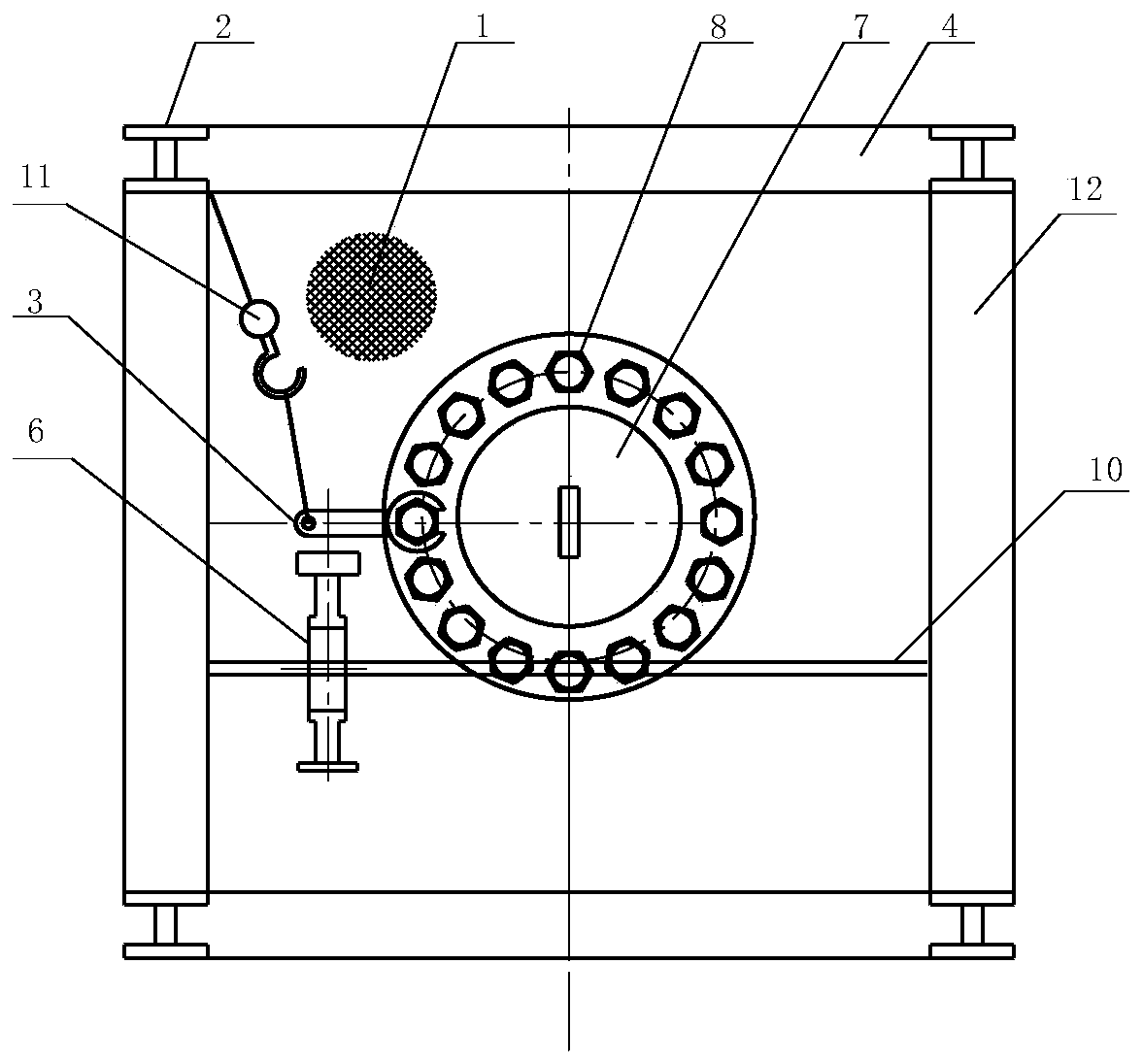

[0029] The patent of this invention was first applied to the overhaul project of high-pressure equipment such as oil separator and ammonia cooler in the maintenance technical service project of a synthetic ammonia / urea plant in a chemical fertilizer company. Diameter connecting bolts are disassembled and reassembled, and the following combination Figure 1 to Figure 7 The patent of the present invention is described further.

[0030] like Figure 1 to Figure 2 As shown, the tools used in the method for dismounting and assembling the super-large connecting bolts of the high-pressure vessel of the present invention include: a support, a suspension chain block 5, a heavy-duty traveling hammer 6, a heavy-duty blow wrench 3 and a chain block 11, and the support frame is placed around the high-pressure container 9 and Above, the support includes: four columns 2, two beams 4, two longitudinal beams 12, an operating platform 1 and a suspension beam 10, the height of the four columns ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com