AGV battery replacement device, replacement method and battery transportation system

A battery replacement and battery technology, which is applied in the field of robotics, can solve problems such as waste and inconvenient personnel, and achieve the effects of reducing workload, easy function realization, and improving accuracy and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

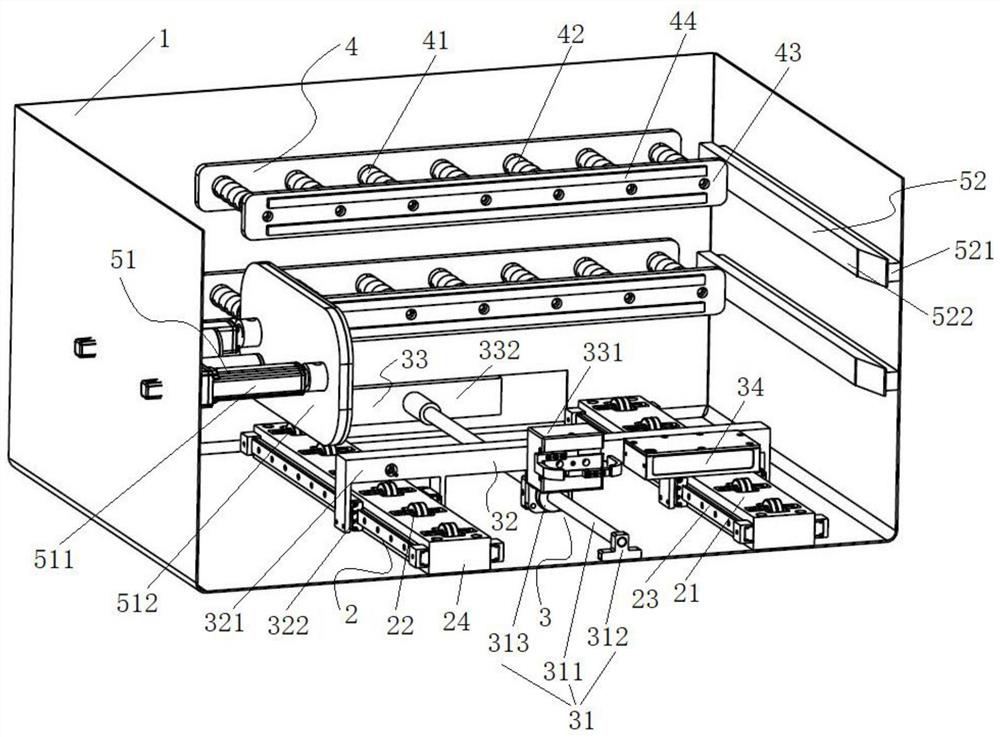

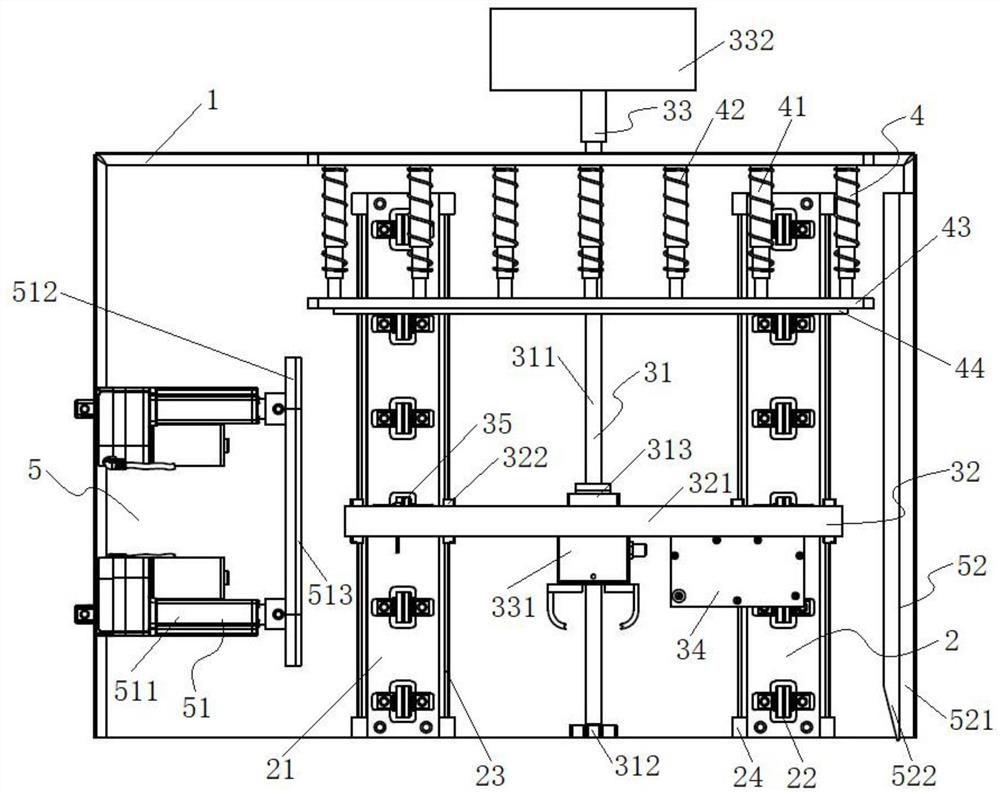

[0048] Such as figure 1 with figure 2 As shown, the AGV battery replacement device includes a housing 1 and a supporting mechanism 2 and a pushing mechanism 3 arranged in the housing 1 . The support mechanism 2 is used to support the AGV battery to be replaced, and the push mechanism 3 is used to drive the AGV battery to be replaced on the support mechanism 2 along its length direction, so that the AGV battery enters and exits the housing 1 .

[0049] In this embodiment, the support mechanism 2 includes at least two support assemblies, and each support assembly is arranged in parallel on the bottom plate of the housing 1 . Wherein, the supporting assembly includes a roller bracket 21 , a roller 22 , a side rail 23 and a rail stopper 24 .

[0050] Along the length direction of the roller bracket 21 , a plurality of rollers 22 are arranged on the roller bracket 21 in parallel and at intervals. By setting rollers 22 on the roller bracket 21, the AGV battery to be replaced can...

Embodiment 2

[0065] On the basis of the AGV battery replacement device provided in Embodiment 1, as figure 1 with figure 2 As shown, the AGV battery replacement device provided in this embodiment also includes a telescopic mechanism 4, and the telescopic mechanism 4 includes at least one set of telescopic components.

[0066] The telescopic assembly protrudes toward the inside of the casing 1 and is arranged on the rear panel of the casing 1 , so that the telescopic assembly is located above the supporting mechanism 2 . Wherein, the telescopic assembly includes a telescopic rod 41 , a spring 42 , a baffle 43 and a first anti-slip rubber 44 . One end of the telescopic rod 41 in the length direction is fixedly connected with the rear panel of the housing 1 , and the other end is fixedly connected with a baffle 43 . A first anti-skid rubber 44 is provided on the front end surface of the baffle plate 43 . A spring 42 is sheathed on the telescopic rod 41, one end of the spring 42 in the len...

Embodiment 3

[0071] On the basis of the AGV battery replacement device provided in embodiment one or embodiment two, such as figure 1 with figure 2 As shown, the AGV battery replacement device provided in this embodiment also includes a fastening mechanism 5 . Wherein, the fastening mechanism 5 includes a push rod assembly 51 and a guide assembly 52 which are arranged oppositely. . The push rod assembly 51 is used in conjunction with the guide assembly 52 to limit the lateral movement of the AGV battery. At the same time, the guide assembly 52 guides the AGV battery during its movement on the roller bracket 21 .

[0072] The push rod assembly 51 includes an electric push rod 511 , a push rod connecting plate 512 and a second anti-skid rubber 513 . Wherein, the electric push rod 511 is parallel to the bottom plate of the housing 1, one end of the electric push rod 511 in its length direction is fixedly connected to the side plate on one side of the housing 1, and the other end is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com