Uniform dispersion device capable of damaging photosynthesis of algae and used for coupling and removing algae

A technology of photosynthesis and uniform dispersion, applied in the field of water treatment, can solve problems such as inapplicability, achieve the effect of thorough photosynthesis and eliminate water pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

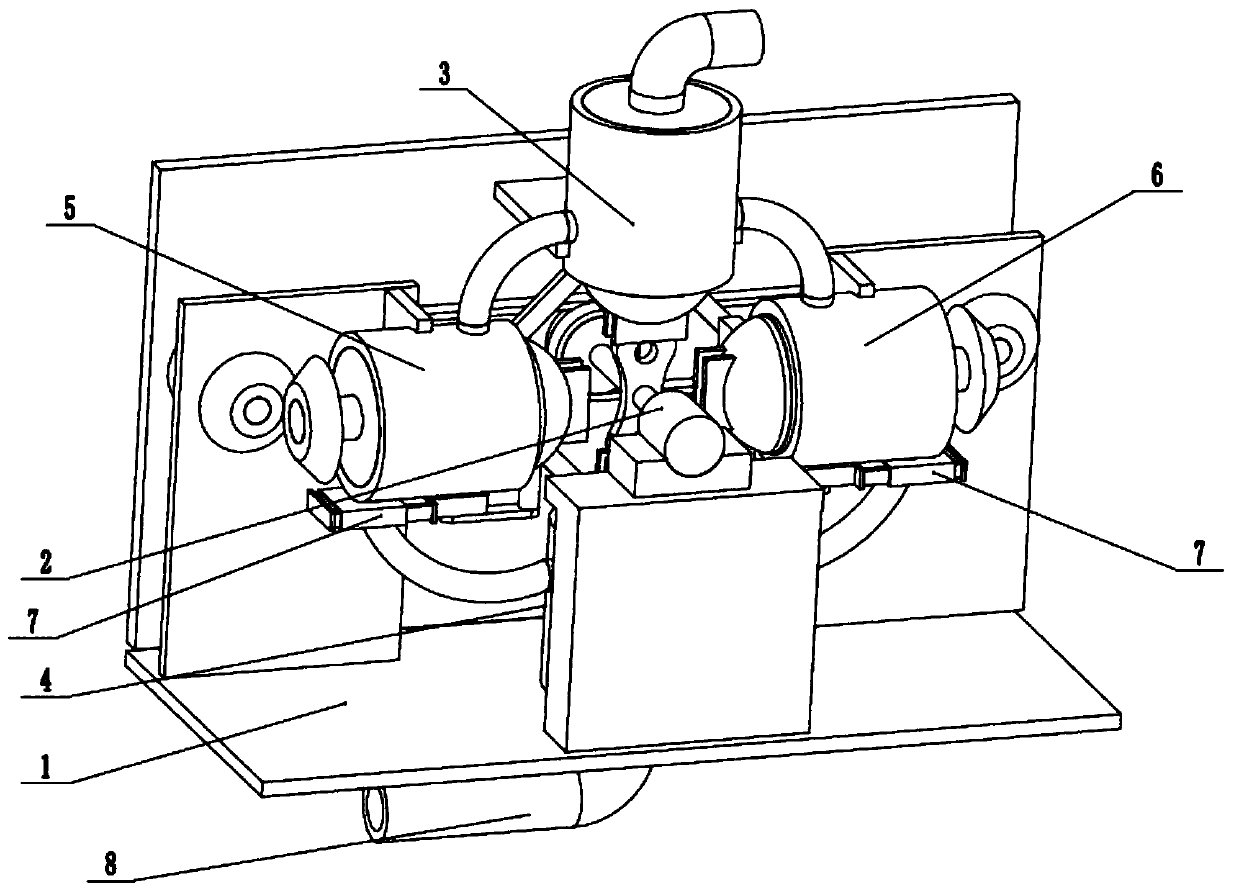

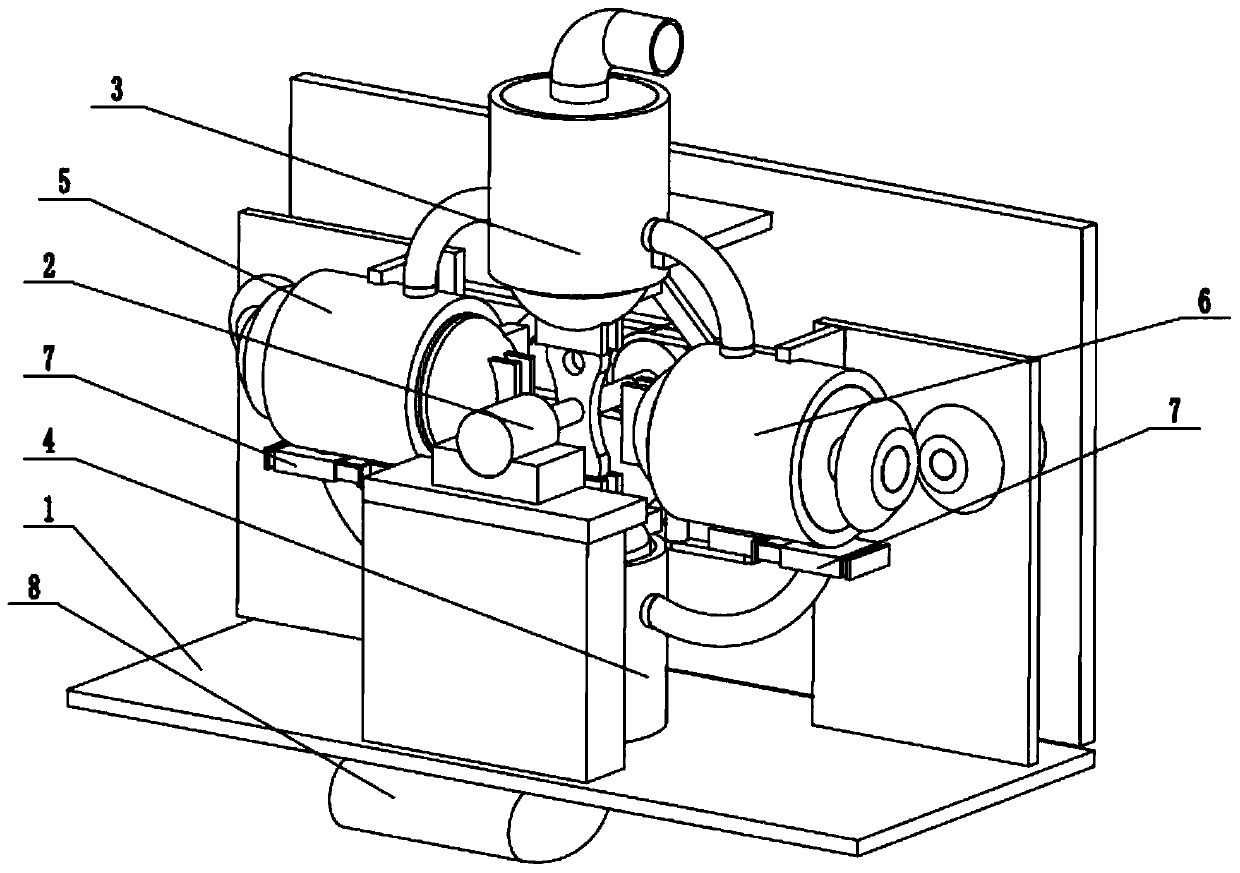

[0030] Such as Figure 1 to Figure 11 As shown, a uniform dispersion device for coupling algae removal to destroy algae photosynthesis, including a base 1, a dispersion drive 2, an upper feeder 3, a lower recovery device 4, a left pressurized agitator 5, and a right pressurized stirrer device 6, dispersive recovery switch 7 and recovery pipe 8, the rear end of the dispersive driver 2 is fixedly connected to the base 1, the front end of the dispersive driver 2 is rotatably connected to the base 1, the upper feeder 3, the lower recovery 4, the left pressure agitator 5 and the right pressure agitator 6 are all fixedly connected on the base 1, and the two ends of the dispersing drive 2 are respectively connected to the left pressure agitator 5 and the right pressure agitator 6 through meshing transmission, The lower end of the upper feeder 3 is respectively hinged to the left pressurized agitator 5 and the right pressurized agitator 6, the left pressurized agitator 5 and the right...

specific Embodiment approach 2

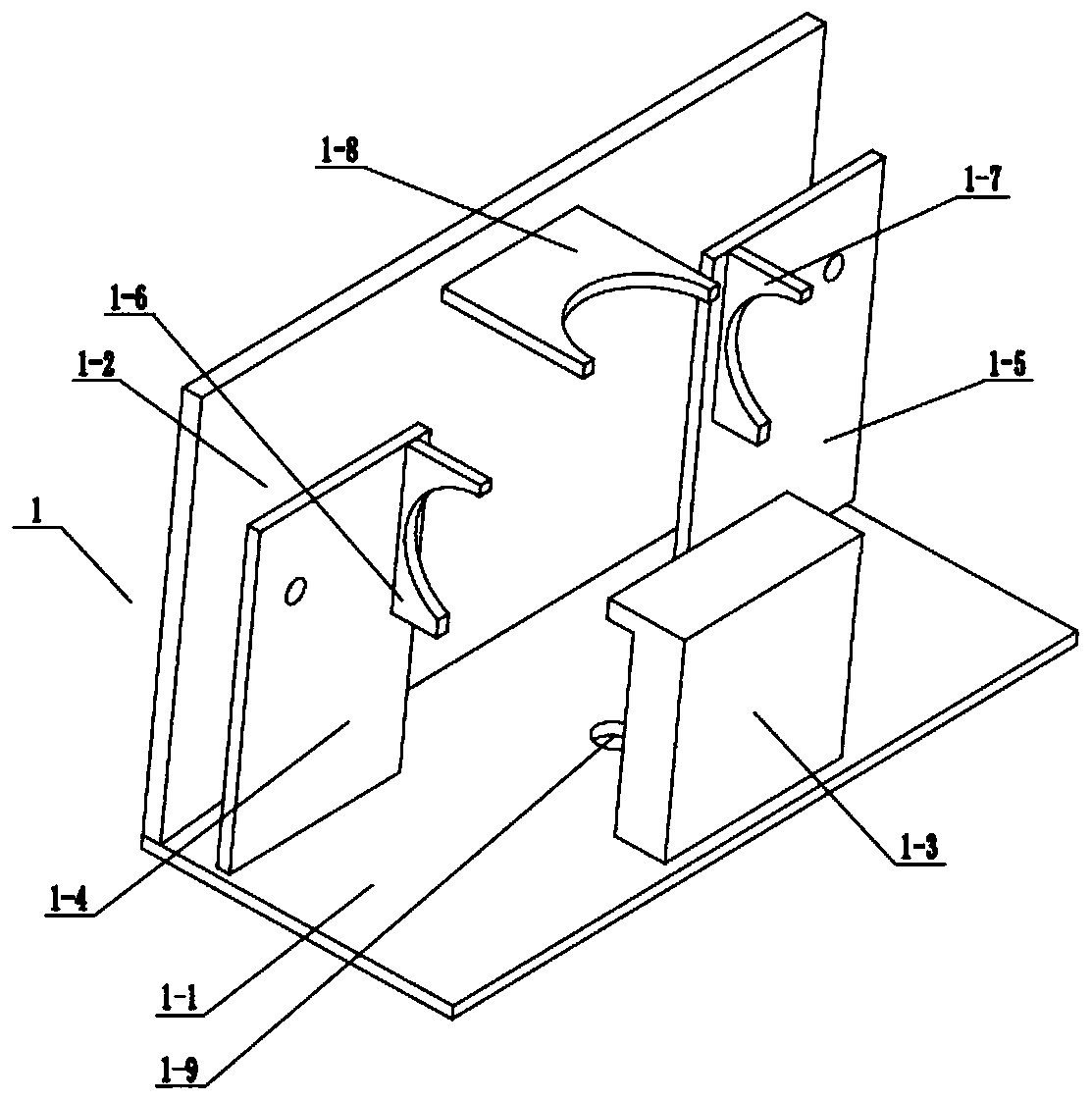

[0031] Such as Figure 1 to Figure 11 As shown, this embodiment further describes the first embodiment, the base 1 includes a bottom plate 1-1, a support vertical plate 1-2, a driver fixing seat 1-3, a left fixing plate 1-4, and a right fixing plate 1 -5. The left agitator fixed frame 1-6, the right agitator fixed frame 1-7, the upper feeder fixed frame 1-8 and the recovery fixed hole 1-9, and the support vertical plate 1-2 is fixedly connected to the bottom plate 1-1 The front end of the driver fixing seat 1-3, the left fixing plate 1-4 and the right fixing plate 1-5 are all fixedly connected to the upper end of the bottom plate 1-1, the left agitator fixing frame 1-6, the right agitator fixing frame 1- 7 and the upper feeder fixing frame 1-8 are respectively fixedly connected to the left fixing plate 1-4, the right fixing plate 1-5 and the supporting vertical plate 1-2, and the recovery fixing holes 1-9 are arranged on the bottom plate 1-1 up and down. The middle end of the...

specific Embodiment approach 3

[0032] Such as Figure 1 to Figure 11 As shown, the second embodiment is further described in this embodiment. The decentralized drive 2 includes a motor fixing seat 2-1, a servo motor 2-2, a central rotating shaft 2-3, a double-groove pulley 2-4, and a left pulley 2. -5, right belt pulley 2-6, center drive concave disc 2-7, left shaft 2-8, right shaft 2-9, left cone drive gear 2-10 and right cone drive gear 2-11, motor holder 2-1 is fixedly connected to the driver fixing base 1-3, the servo motor 2-2 is fixedly connected to the motor fixing base 2-1, and the rear end of the central rotating shaft 2-3 is connected to the transmission of the servo motor 2-2 through a coupling Axle, the front end of central rotating shaft 2-3 is rotatably connected in support vertical plate 1-2, and double-groove pulley 2-4 and center driving concave disk 2-7 are all fixedly connected on the central rotating shaft 2-3, and double-groove pulley 2- 4 Connect the left pulley 2-5 and the right pull...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com