Draining device for fuel delivery pump suction port and assembly method thereof

An assembly method and suction port technology, which are applied to parts, pump elements, machines/engines, etc. of elastic fluid pumping devices, can solve the problem of severe vibration of oil pumps and pipelines, which affects the safety of production and operation, and is difficult to meet The requirements for the distance of the straight pipe section at the inlet of the oil pump, etc., to ensure normal and stable operation, simple structure, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

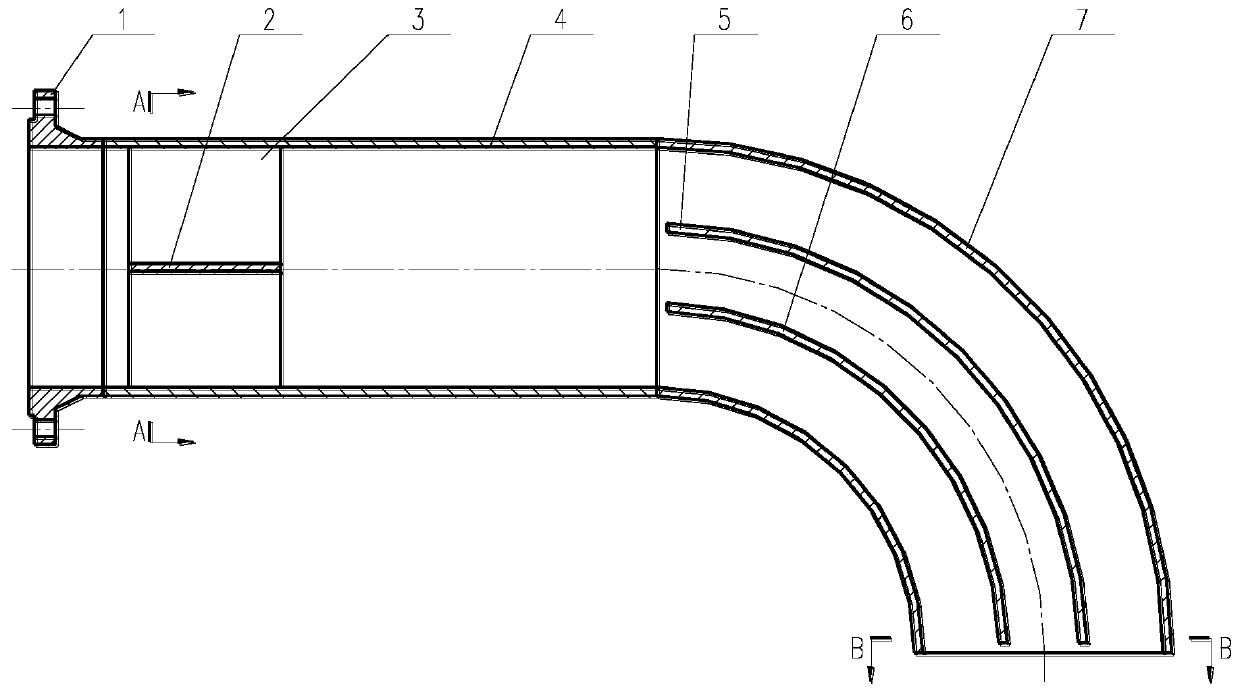

[0029] Example 1, such as Figure 1-3 As shown, a flow trap for the suction port of the oil delivery pump according to the embodiment of the present invention includes: a matching flange 1, a straight pipe 4 and a 90° elbow 7, and the two ends of the straight pipe 4 are connected with the matching flange 1 and the 90 ° elbow 7 welding.

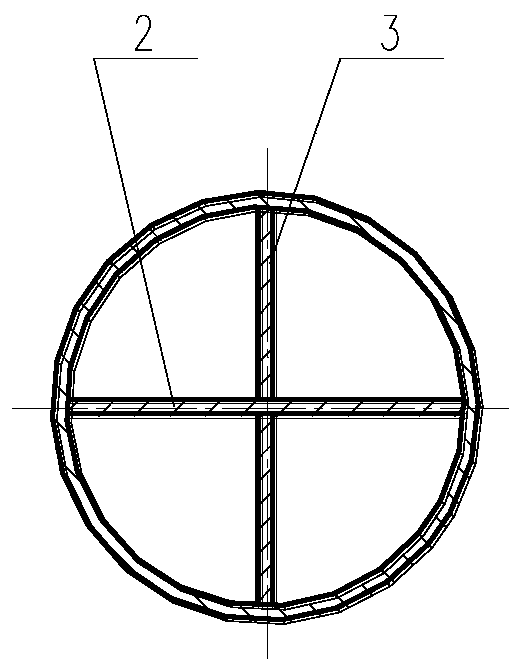

[0030] The straight pipe 4 is placed horizontally, and the horizontal drain sheet 2 and the vertical drain sheet 3 are welded on the side close to the mating flange 1 . The horizontal drainage sheet 2 is welded on the inner wall of the straight pipe 4, and the horizontal drainage sheet 2 is located on the central axis of the straight pipe 4 in the horizontal direction. The vertical dredging sheet 3 is two pieces, symmetrically arranged between the inner wall of the straight pipe 4 and the horizontal dredging sheet 2, and the two vertical dredging sheets 3 are all located on the central axis of the vertical direction of the straight pipe 4, an...

Embodiment 2

[0034] Embodiment 2, an assembly method of a flow trap used for the suction port of an oil transfer pump, the assembly method includes the following steps:

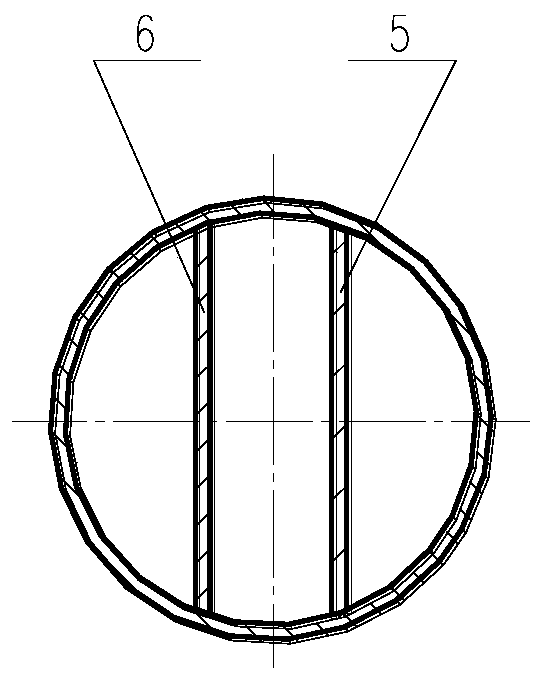

[0035] Step 1, process the horizontal drainage sheet 2, the vertical drainage sheet 3, the outer drainage sheet 5 and the inner drainage sheet 6 according to the requirements of the part drawing.

[0036] Step 2: Weld the horizontal drain sheet 2 with the inner wall of the straight pipe 4, and weld the two vertical drain sheets 3 with the horizontal drain sheet 2 and the inner wall of the straight pipe 4 to complete the horizontal drain sheet 2 and the horizontal drain sheet 2 and the assembly welding of straight pipe 4.

[0037] Among them, the two ends of the horizontal dredging sheet 2 are spot-welded, and the rest are spot-welded at intervals; the two ends of the vertical dredging sheet 3 are spot-welded, and the rest are spot-welded at intervals.

[0038] Step 3, welding the outer drain sheet 5 and the inner drain s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com