Hydraulic control system for rear matching trailer wheel set of shield machine

A hydraulic control system and rear supporting technology, which is applied to fluid pressure actuating system components, mechanical equipment, fluid pressure actuating devices, etc. demand, cost savings, guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

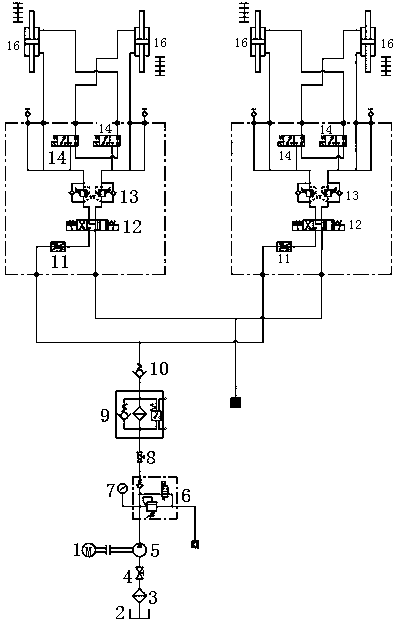

[0020] Embodiment 1, a hydraulic control system for trailer wheel pairs behind a shield machine, such as Figure 1-4 As shown, the hydraulic pump 5 driven by the motor 1 is included, the oil inlet of the hydraulic pump 5 is connected with the oil tank 2, and the oil outlet is connected with the hydraulic control valve and the leveling cylinder 16 in turn through the hydraulic pipeline, and the telescopic cylinder of the leveling oil cylinder 16 It is connected with the wheel set of the matching trailer behind the shield machine. Through the oil supply of the hydraulic pump 5 to the leveling cylinder 16, the state of the wheel set of the supporting trailer behind the shield machine can be conveniently adjusted, thereby preventing the supporting trailer of the shield machine from tilting away from the predetermined direction.

[0021] The leveling oil cylinder 16 has a built-in displacement sensor for monitoring the action of the telescopic cylinder, and the displacement sensor ...

Embodiment 2

[0024] Embodiment 2, a hydraulic control system for a trailer wheel pair behind a shield machine, the leveling cylinder 16 is a double-rod cylinder, and the double-rod cylinder includes a first oil chamber and a second oil chamber that are symmetrical to each other, and the first The longitudinal sectional area of the oil chamber and the second oil chamber are equal, which ensures the accuracy of the alignment of the left and right wheelsets.

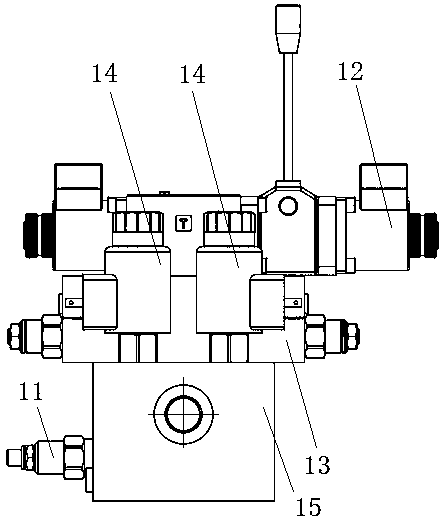

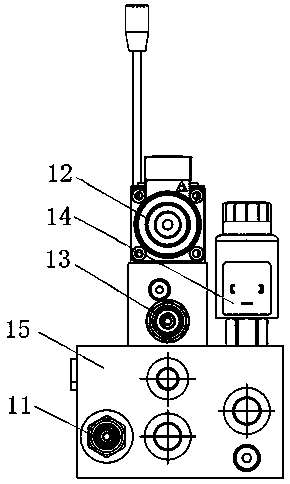

[0025] The electromagnetic reversing valve 12 is arranged in front of the electromagnetic ball valve 14. The electromagnetic reversing valve 12 is provided with two output oil pipes, one of which is connected to the first oil chamber, and the other is connected to the oil inlet of the electromagnetic ball valve 14. connected, and the oil outlet of the electromagnetic ball valve 14 is connected with the second oil chamber. The PLC control unit separately controls the electromagnetic ball valve 14 and the electromagnetic reversing valve...

Embodiment 3

[0033] Embodiment 3 is a hydraulic control system for a trailing wheel set behind a shield machine, and a superposition balance valve 13 is arranged between the electromagnetic reversing valve 12 and the electromagnetic ball valve 14 . The application of the superimposed balance valve 13 can balance the load and make the operation of the double-rod cylinder more stable. At the same time, the superimposed balance valve 13 can maintain the pressure of the double-rod cylinder to maintain the load.

[0034] Other structures of this embodiment are the same as Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com