Device and method for measuring surface tension coefficient

A technology of surface tension coefficient and measuring device, applied in the field of physical quantity measurement, can solve problems such as low precision, influence of surface tension, inability to effectively determine and measure the absolute position of the rising height and boundary light, and avoid systematic errors and eliminate contact angles. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments.

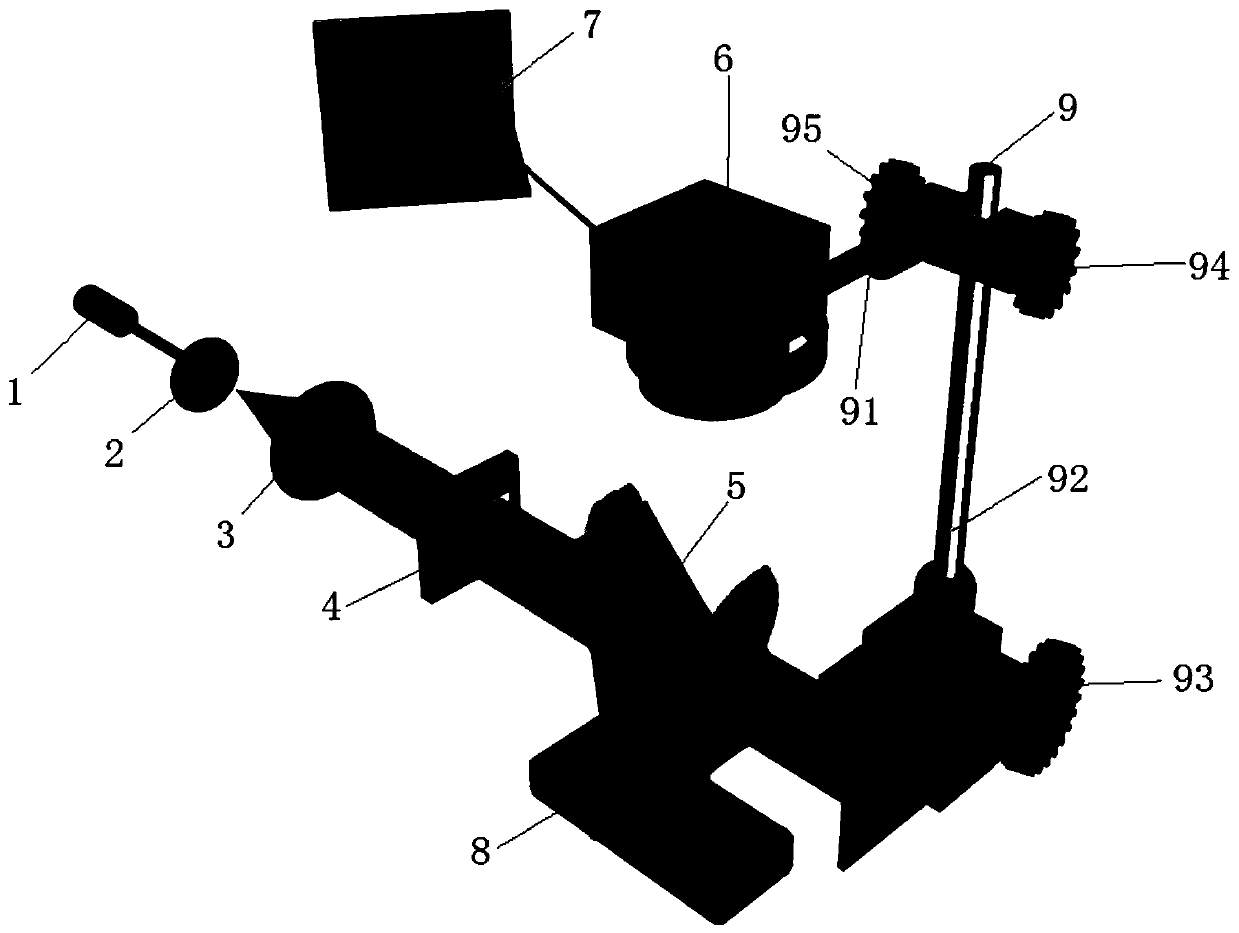

[0036] Reference attached figure 1 As shown, a surface tension coefficient measuring device of the present invention includes a light source 1, a beam expander 2, a convex lens 3, a slit stop 4, a half mirror 5, a linear array CCD 6, a computer 7, a flat panel 8 and a support 9 ;

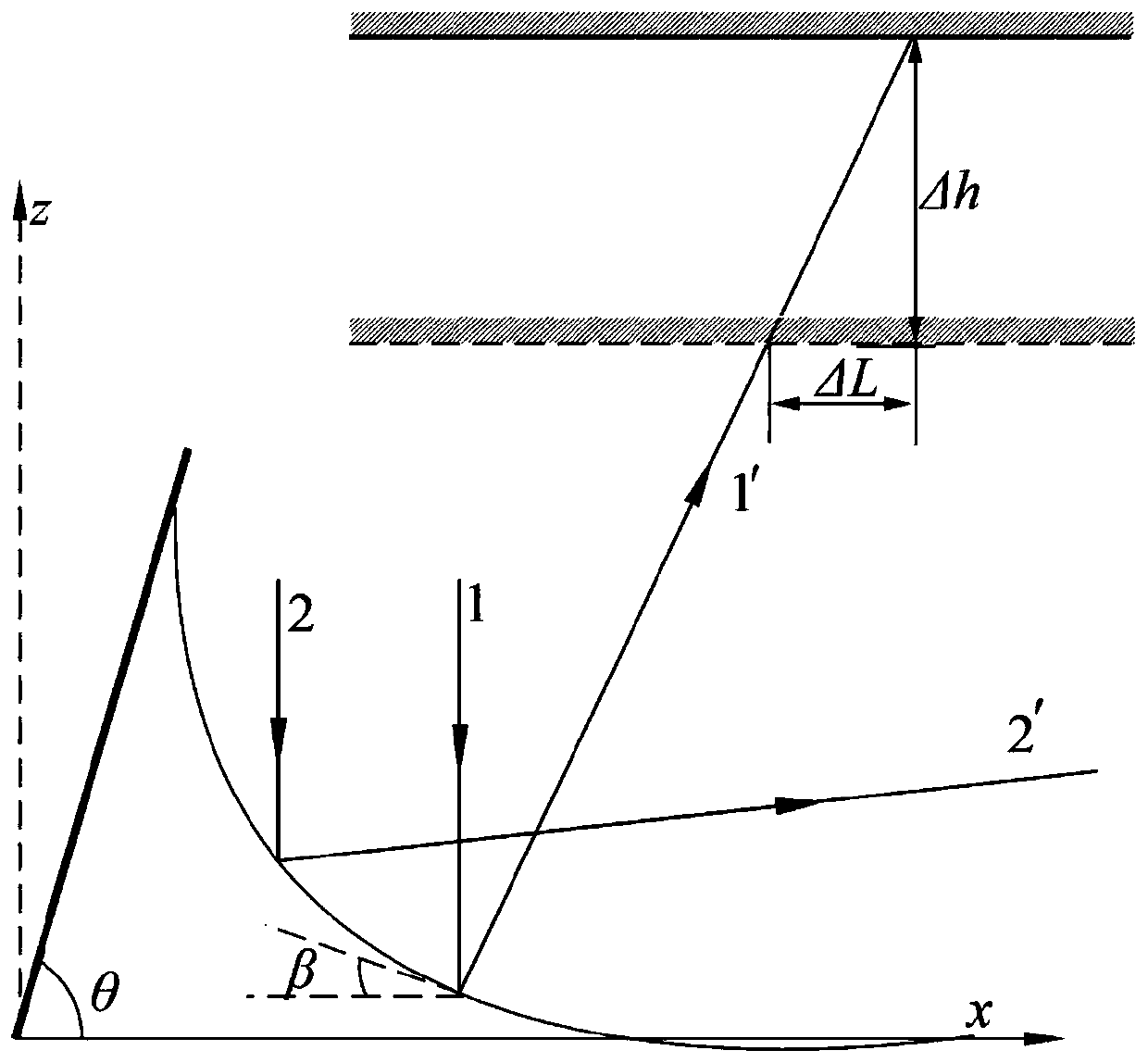

[0037] The light source 1 adopts a laser, and the light source 1 is used to generate a light beam, and the light beam is a parallel light beam; the light source 1 emits a Gaussian beam and passes through a beam expander 2 and a convex lens 3 on the path to form a collimated and parallel light beam and then irradiates it on the slit diaphragm 4; A slit diaphragm 4 is arranged on the parallel light path, and the position of the incident light on the curved liquid surface is controlled by using the slit diaphragm 4 to control the boundary of the parallel light rays; A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com