Transient voltage suppression device

A technology for suppressing device and transient voltage, applied in circuits, electrical components, electrical solid devices, etc., can solve the problem of high snapback voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0041] The transient voltage suppression device of this embodiment includes a first heavily doped region disposed in a well and a second heavily doped region disposed under the first heavily doped region. The above-mentioned first heavily doped region and the second heavily doped region have opposite conductivity types, so as to reduce the snapback voltage of the transient voltage suppression device.

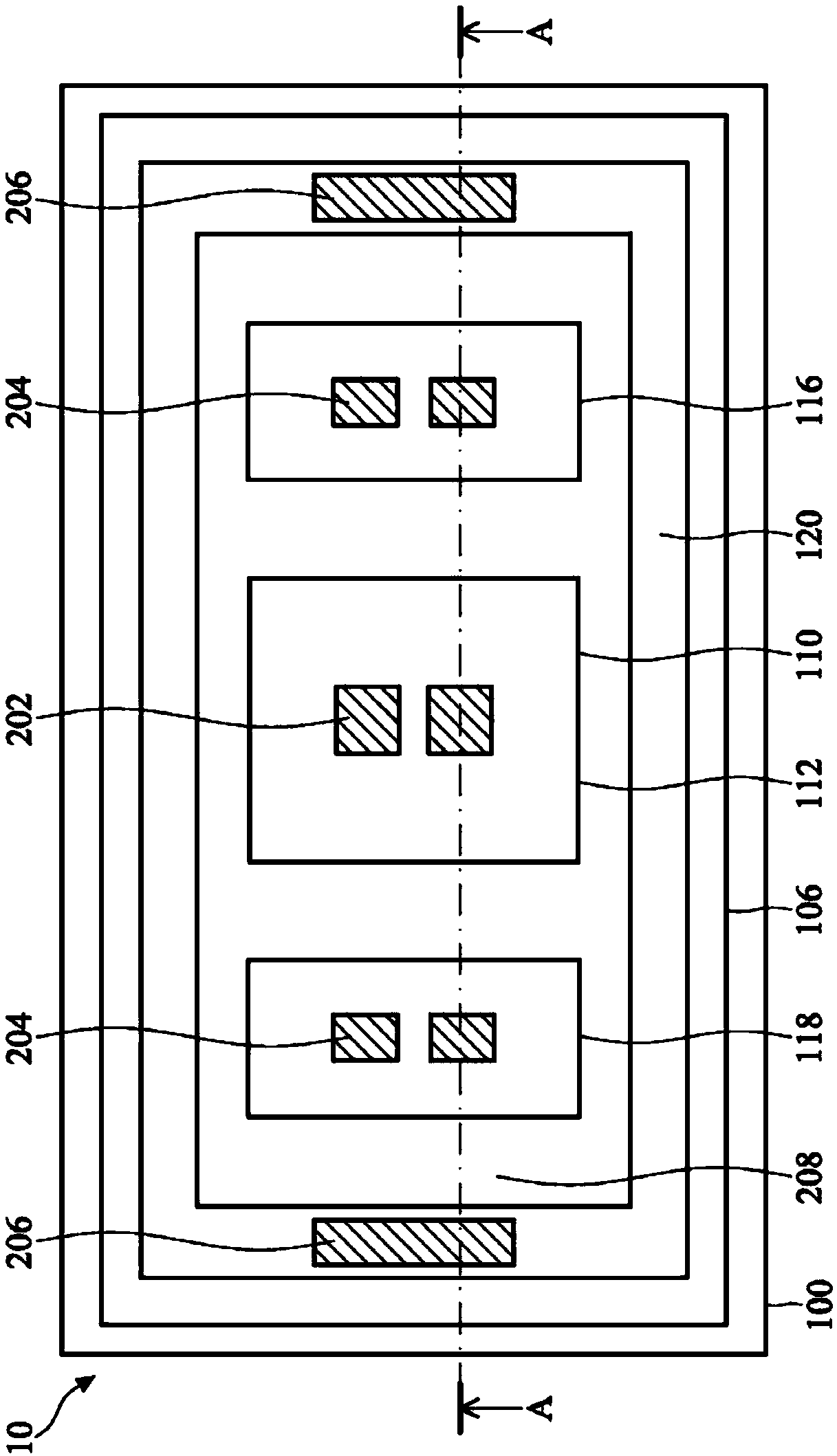

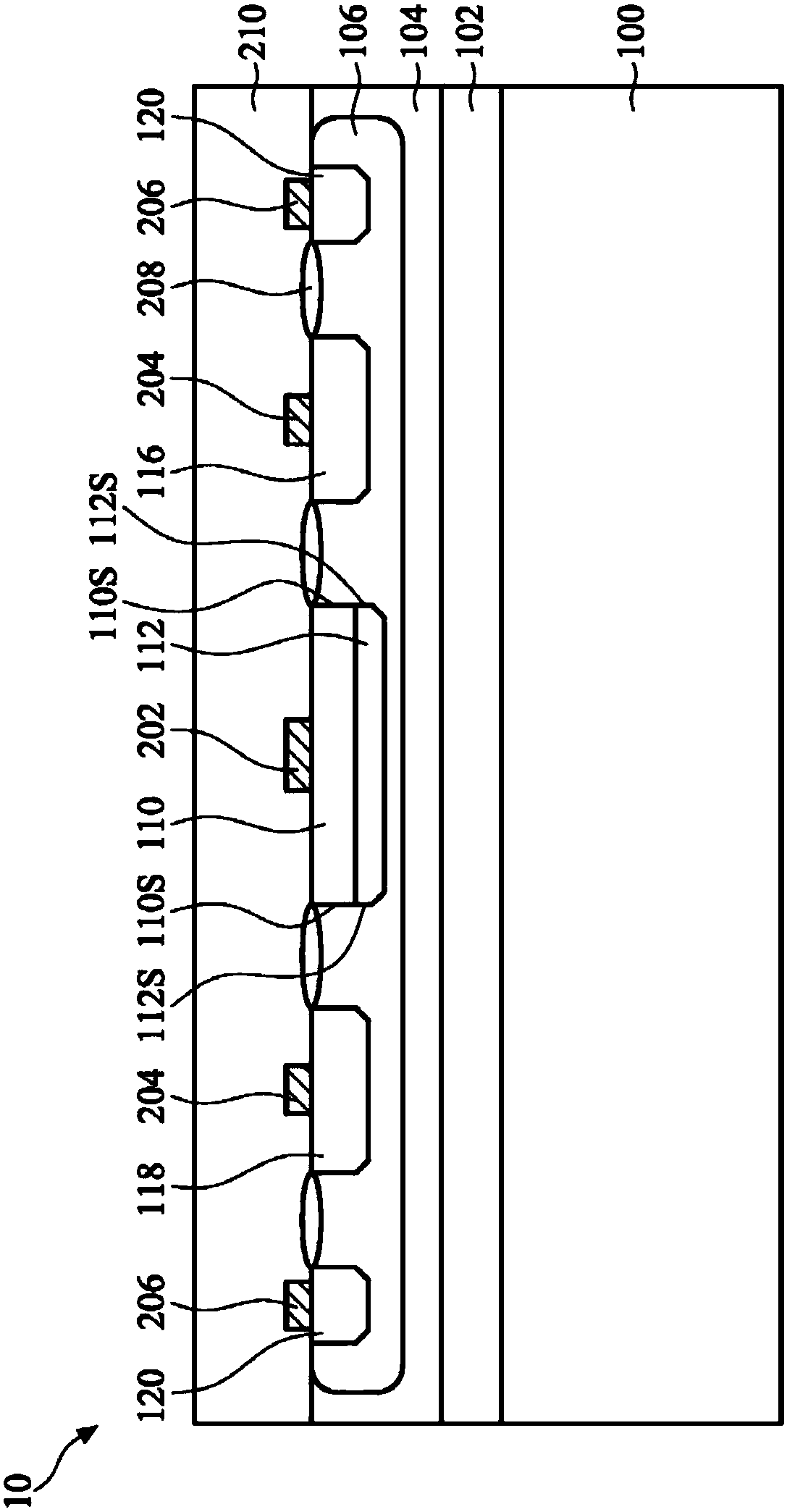

[0042] Figure 1A and Figure 1B A top view and a cross-sectional view of the transient voltage suppression device 10 of this embodiment are shown. In detail, Figure 1B for along Figure 1A The section view obtained by section line A-A.

[0043] Such as Figure 1A and Figure 1B As shown, the transient voltage suppression device 10 of this embodiment generally includes a substrate 100, a first semiconductor layer 102 disposed on the substrate 100, a second semiconductor layer 104 disposed on the first semiconductor layer 102, and a second semiconductor layer 104 disposed on ...

no. 2 example

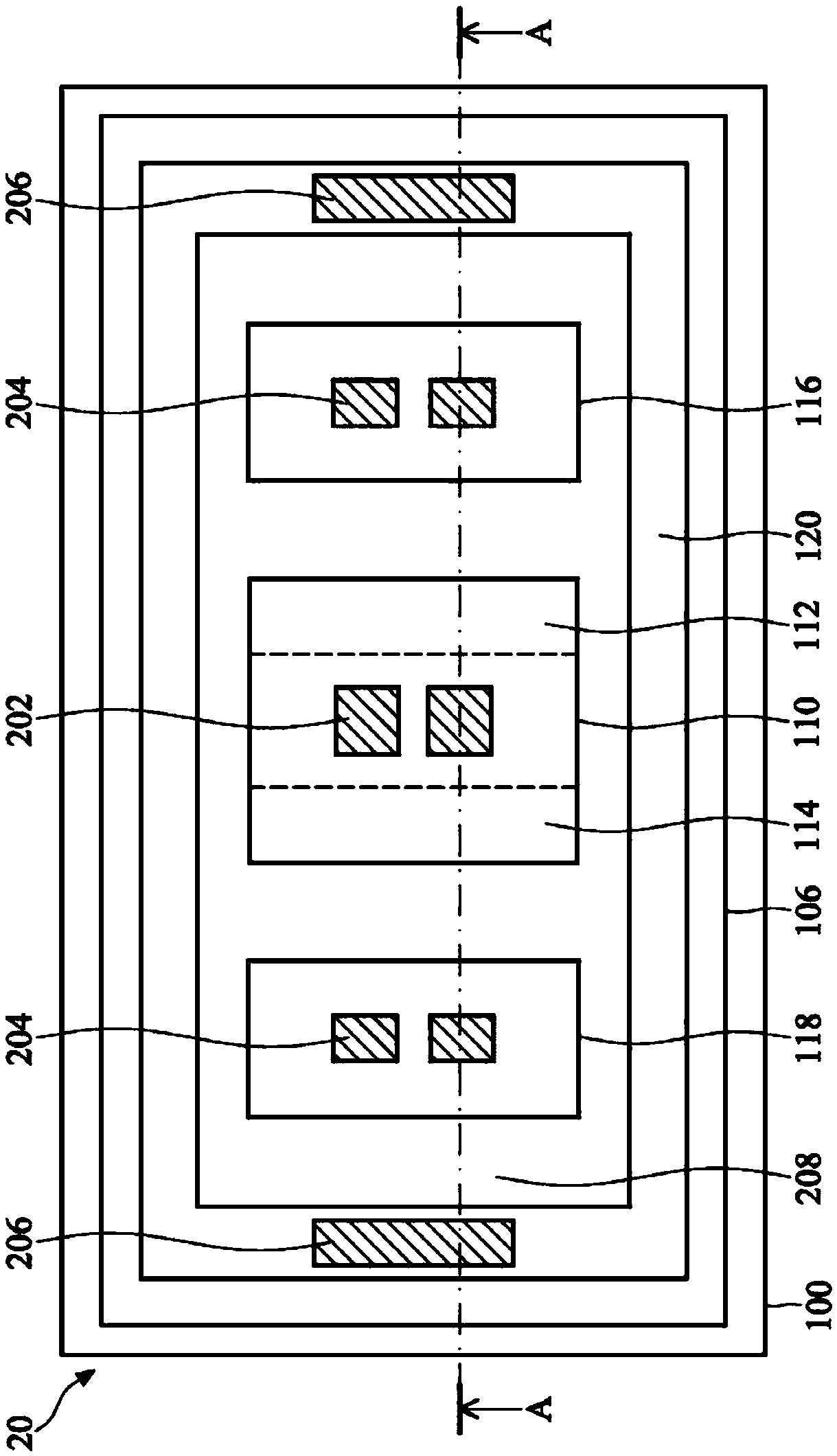

[0080] One difference between this embodiment and the first embodiment is that the transient voltage suppression device of this embodiment includes a separate second heavily doped region of the first conductivity type disposed under the first heavily doped region of the second conductivity type. region and the third heavily doped region, which can further increase the secondary breakdown current and further reduce the snapback voltage.

[0081] It should be noted that, unless otherwise specified, the same or similar components in this embodiment and the previous embodiments will be denoted by the same reference numerals, and their forming methods can also be the same or similar to those of the previous embodiments.

[0082] Figure 2A and Figure 2B A top view and a cross-sectional view of the transient voltage suppression device 20 of this embodiment are shown. In detail, Figure 2B for along Figure 2A The section view obtained by section line A-A.

[0083] Such as Figu...

no. 3 example

[0092] One difference between this embodiment and the second embodiment is that the transient voltage suppression device of this embodiment includes a first well and a second well of the first conductivity type separated, which can further increase the secondary breakdown current and further reduce the snapback Voltage.

[0093] It should be noted that, unless otherwise specified, the same or similar components in this embodiment and the previous embodiments will be denoted by the same reference numerals, and their forming methods can also be the same or similar to those of the previous embodiments.

[0094] Figure 3A and Figure 3B A top view and a cross-sectional view of the transient voltage suppression device 30 of this embodiment are shown. In detail, Figure 3B for along Figure 3A The section view obtained by section line A-A.

[0095] Such as Figure 3A and Figure 3B As shown, the second semiconductor layer 104 of the second conductivity type of the transient ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com