Hydraulic engine powered winch

A winch mill, hydraulic technology, applied in the direction of the spring mechanism, hoisting device, etc., can solve the problems of hidden safety hazards, high technical requirements of operators, and limited braking area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

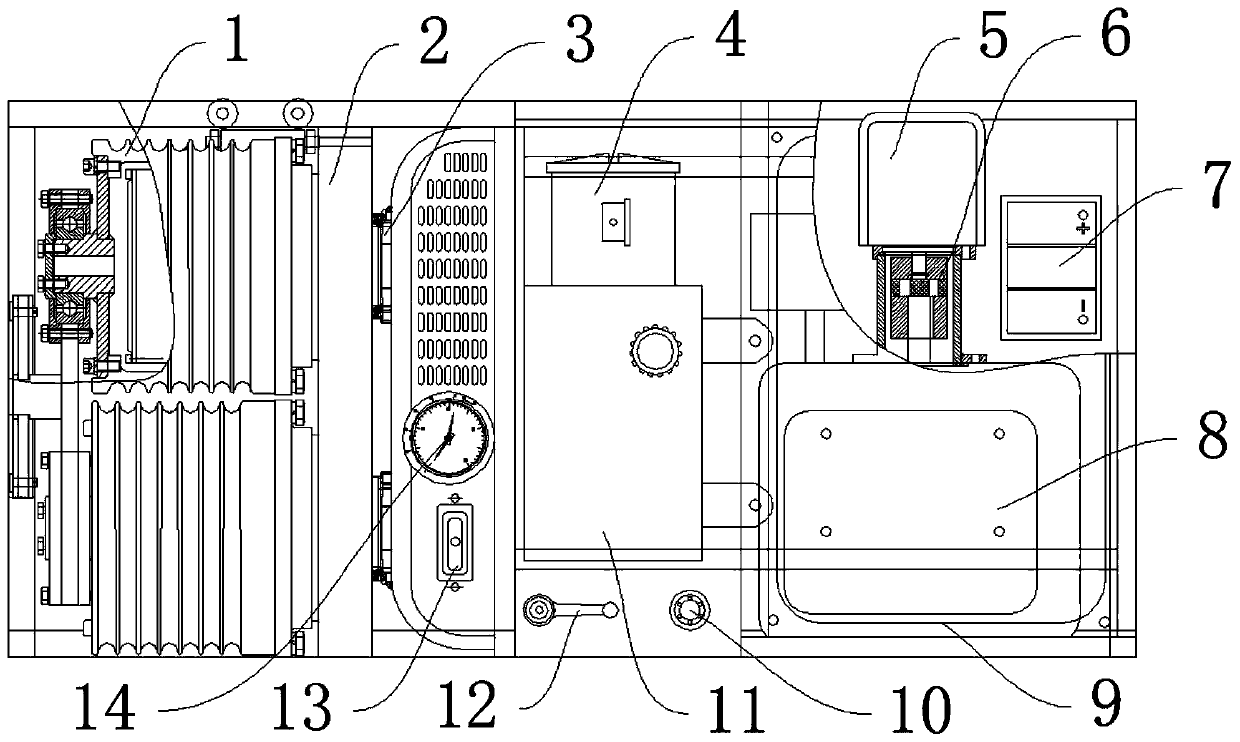

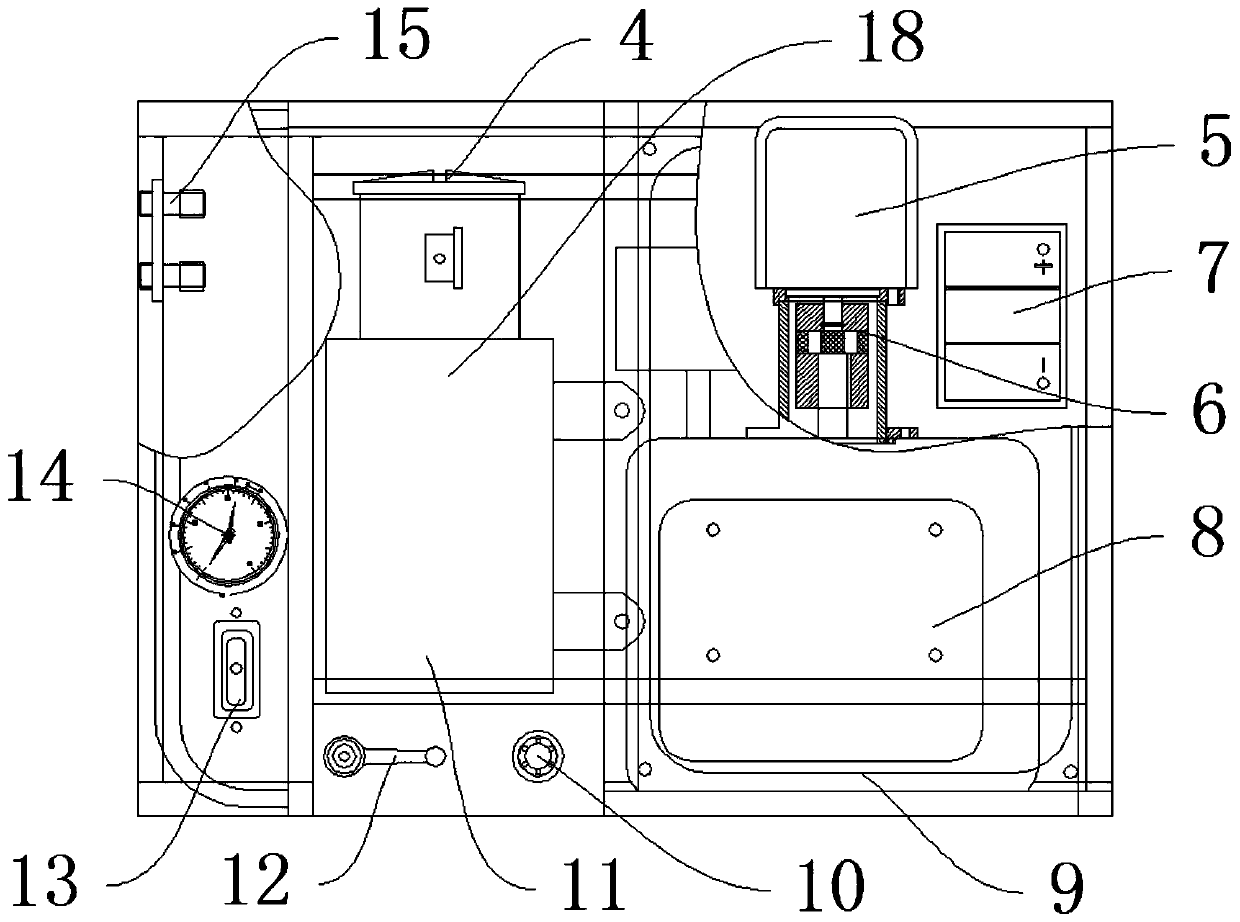

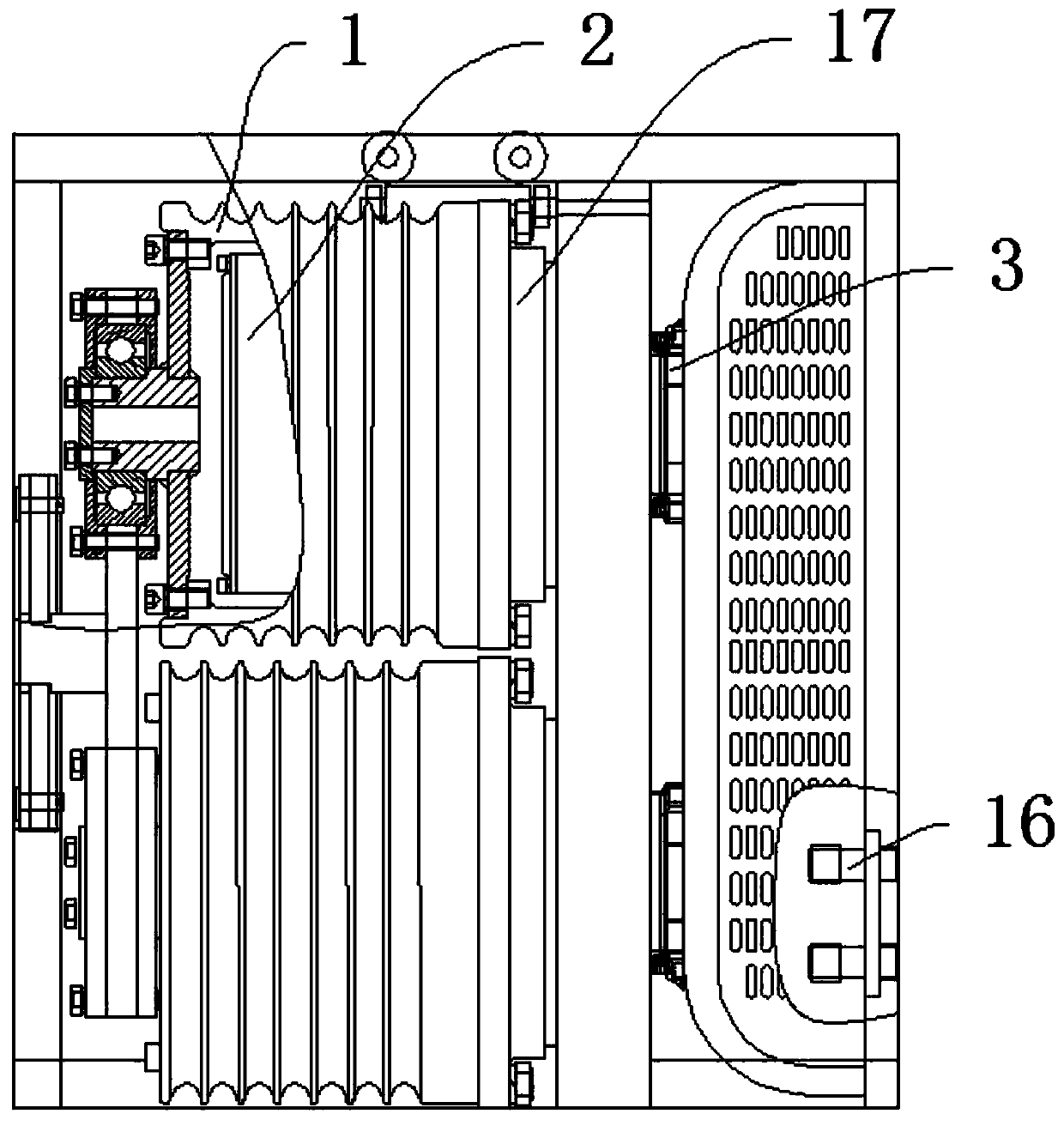

[0040] like Figure 1-Figure 3 As shown, the hydraulic winch mill includes a gasoline engine 8, a hydraulic variable pump 5, and a drum 1. A gasoline tank 9 is arranged behind the gasoline engine 8 to store gasoline. A coupling 6 is arranged on the gasoline engine 8 to transmit power. The coupling 6- A battery 7 is arranged on the side to provide starting power, a hydraulic variable pump 5 is arranged on the coupling 6 to generate hydraulic pressure, a radiator 11 is arranged on one side of the gasoline engine 8 to increase heat dissipation of the hydraulic oil tank 18, and a hydraulic oil tank is arranged behind the radiator 11 18, containing hydraulic oil, a filter 4 is arranged on the hydraulic oil tank 18 to filter the hydraulic oil, and a relief valve 10 is arranged in front of the radiator 11, and the maximum traction force is limited by adjusting the size, and a ball valve is arranged on the side of the relief valve 10 12. It is used to control the work of the brake 17....

Embodiment 2

[0042] The difference between this embodiment and embodiment 1 is:

[0043] The coupling 6 is respectively connected with the gasoline engine 8 and the hydraulic variable displacement pump 5 using a flat key, and the flat key connection facilitates the smooth transmission of the power of the gasoline engine 8 to the hydraulic variable displacement pump 5 .

[0044] Working principle: The gasoline engine 8 burns gasoline to generate power, and the power is transmitted to the hydraulic variable pump 5 through the coupling 6, and the hydraulic variable pump 5 converts mechanical energy into hydraulic energy, and then passes through the middle of the first quick-change joint 15 and the second quick-change joint 16 The connected oil pipe transmits the hydraulic energy to the hydraulic motor 3. The hydraulic motor 3 converts the hydraulic energy into mechanical energy and transmits it to the reducer 2. The reducer 2 transmits the mechanical energy to the drum 1 after decelerating and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com