Preparing technology of pepper oil

A technology of Chinese prickly ash oil and process, which is applied in the direction of fat oil/fat production and fat production, can solve the problems of high production cost, high operation difficulty and high equipment cost, and achieve the effects of low equipment cost investment, simple operation process and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

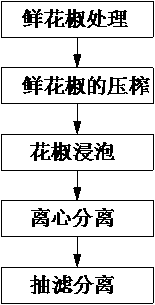

Image

Examples

Embodiment 1

[0026] A kind of Chinese prickly ash oil preparation process, described preparation process comprises the steps:

[0027] (1) Fresh pepper treatment, pick fresh peppers with good quality, wash fresh peppers, put fresh peppers at a temperature of 105°C for softening treatment;

[0028] (2) Pressing fresh peppers

[0029] a. Put the softened fresh pepper into the crushing equipment for preliminary grinding;

[0030] b. Then put the ground fresh pepper into the press, start the press, stop pressing until the oil bag on the surface of the fresh pepper breaks, and obtain the pepper oil raw material;

[0031] (3) Soak the peppercorns, pour the peppercorn oil raw materials obtained in step (2) into a container, add warm oil into the container, make the warm oil spread over the peppercorn surface, seal the container, and obtain the peppercorn oil stock solution after soaking;

[0032] (4) Centrifuge, pour out the stock solution of pepper oil obtained in step (3) from the container, ...

Embodiment 2

[0045] A kind of Chinese prickly ash oil preparation process, described preparation process comprises the steps:

[0046] (1) Fresh pepper treatment, pick fresh peppers with good quality, wash fresh peppers, put fresh peppers at a temperature of 105°C for softening treatment;

[0047] (2) Pressing fresh peppers

[0048] a. Put the softened fresh pepper into the crushing equipment for preliminary grinding;

[0049] b. Then put the ground fresh pepper into the press, start the press, stop pressing until the oil bag on the surface of the fresh pepper breaks, and obtain the pepper oil raw material;

[0050] (3) Soak the peppercorns, pour the peppercorn oil raw materials obtained in step (2) into a container, add warm oil into the container, make the warm oil spread over the peppercorn surface, seal the container, and obtain the peppercorn oil stock solution after soaking;

[0051] (4) Centrifuge, pour out the stock solution of pepper oil obtained in step (3) from the container, ...

Embodiment 3

[0064] A kind of Chinese prickly ash oil preparation process, described preparation process comprises the steps:

[0065] (1) Fresh pepper treatment, pick fresh peppers with good quality, wash fresh peppers, put fresh peppers at a temperature of 105°C for softening treatment;

[0066] (2) Pressing fresh peppers

[0067] a. Put the softened fresh pepper into the crushing equipment for preliminary grinding;

[0068] b. Then put the ground fresh pepper into the press, start the press, stop pressing until the oil bag on the surface of the fresh pepper breaks, and obtain the pepper oil raw material;

[0069] (3) Soak the peppercorns, pour the peppercorn oil raw materials obtained in step (2) into a container, add warm oil into the container, make the warm oil spread over the peppercorn surface, seal the container, and obtain the peppercorn oil stock solution after soaking;

[0070] (4) Centrifuge, pour out the stock solution of pepper oil obtained in step (3) from the container, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com