Synthesized leather

A technology of synthetic leather and ultraviolet rays, which is applied in the field of synthetic leather, can solve problems such as peelability, poor low-temperature buckling resistance, perforation and rupture, and reduction of dynamic physical properties of the foam layer, so as to reduce peeling, improve performance such as low-temperature buckling resistance, The effect of good bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

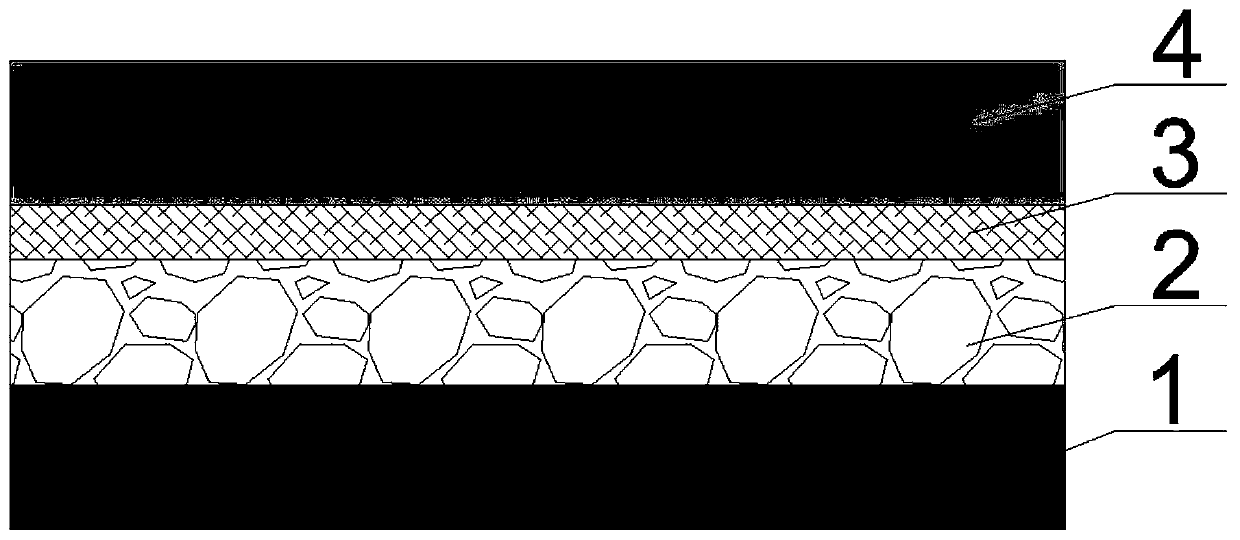

[0027] Using a coating machine, the surface layer liquid, the ultraviolet absorbing coating with an ultraviolet absorber content of 10%, and the polyurethane of the foaming adhesive layer are coated on the release paper in sequence. Among them, the coating amount of UV absorbing coating is 20g / m 2 . Finally, the base cloth layer is pasted on the foaming adhesive layer to obtain synthetic leather.

[0028] at 1.2W / m 2 Under the highest light intensity, after 144 hours of high sun exposure, the peel strength of synthetic leather is 16N / cm, the ordinary leather with the same formula without special UV absorbing coating is 12N / cm, and the low temperature buckling resistance is minus 20 degrees and 30,000 times pass.

Embodiment 2

[0030] Using a coating machine, the surface layer liquid, the ultraviolet absorbing coating with an ultraviolet absorber consumption of 5%, and the polyurethane of the foaming adhesive layer are coated on the release paper in sequence. Among them, the coating amount of UV absorbing coating is 22g / m 2 . Finally, the base cloth is pasted on the foaming layer to obtain synthetic leather.

[0031] at 1.2W / m 2 Under the highest light intensity, after 144 hours of high sun exposure, the peel strength of synthetic leather is 18N / cm, the ordinary leather with the same formula without special UV absorbing coating is 12N / cm, and the low temperature buckling resistance is minus 20 degrees and 30,000 times pass.

Embodiment 3

[0033] Using a coating machine, the surface layer liquid, the ultraviolet absorbing coating with an ultraviolet absorber content of 25%, and the polyurethane of the foaming adhesive layer are coated on the release paper in sequence. Among them, the coating amount of UV absorbing coating is 15g / m 2 . Finally, the base cloth is pasted on the foaming layer to obtain synthetic leather.

[0034] at 1.2W / m 2 Under the highest light intensity, after 144 hours of high sun exposure, the peel strength of synthetic leather is 17N / cm, and the ordinary leather with the same formula without special UV absorbing coating is 12N / cm, and the low temperature buckling resistance is minus 20 degrees and 30,000 times pass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com