Automatic steam curing system for second lining concrete of single track tunnel and construction method

A technology of steam curing and tunneling, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc. It can solve the problems of durability impact, unstable humidity, and difficult control of water temperature, etc., and achieve the effect of improving maintenance efficiency, reducing labor intensity, and convenient walking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

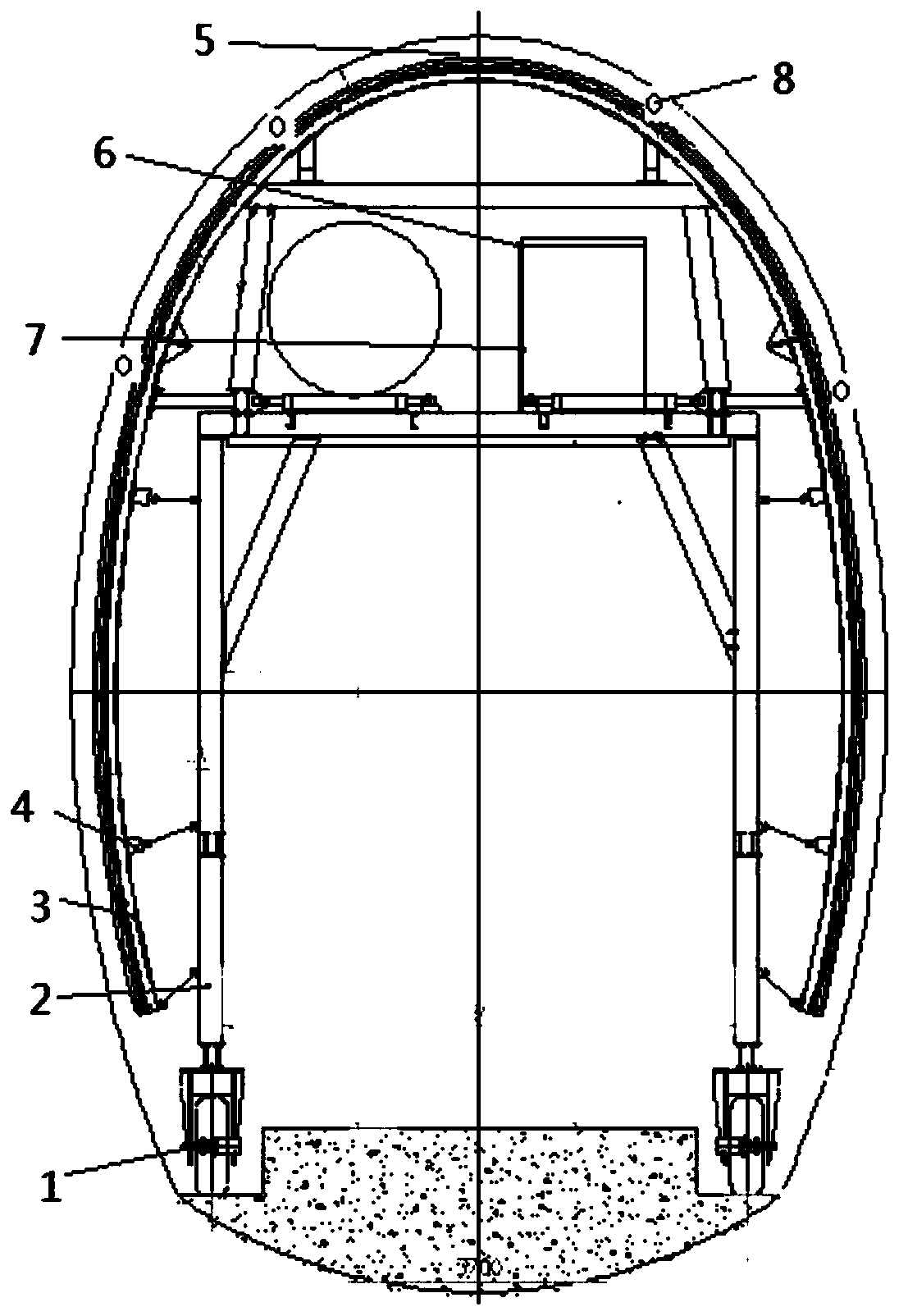

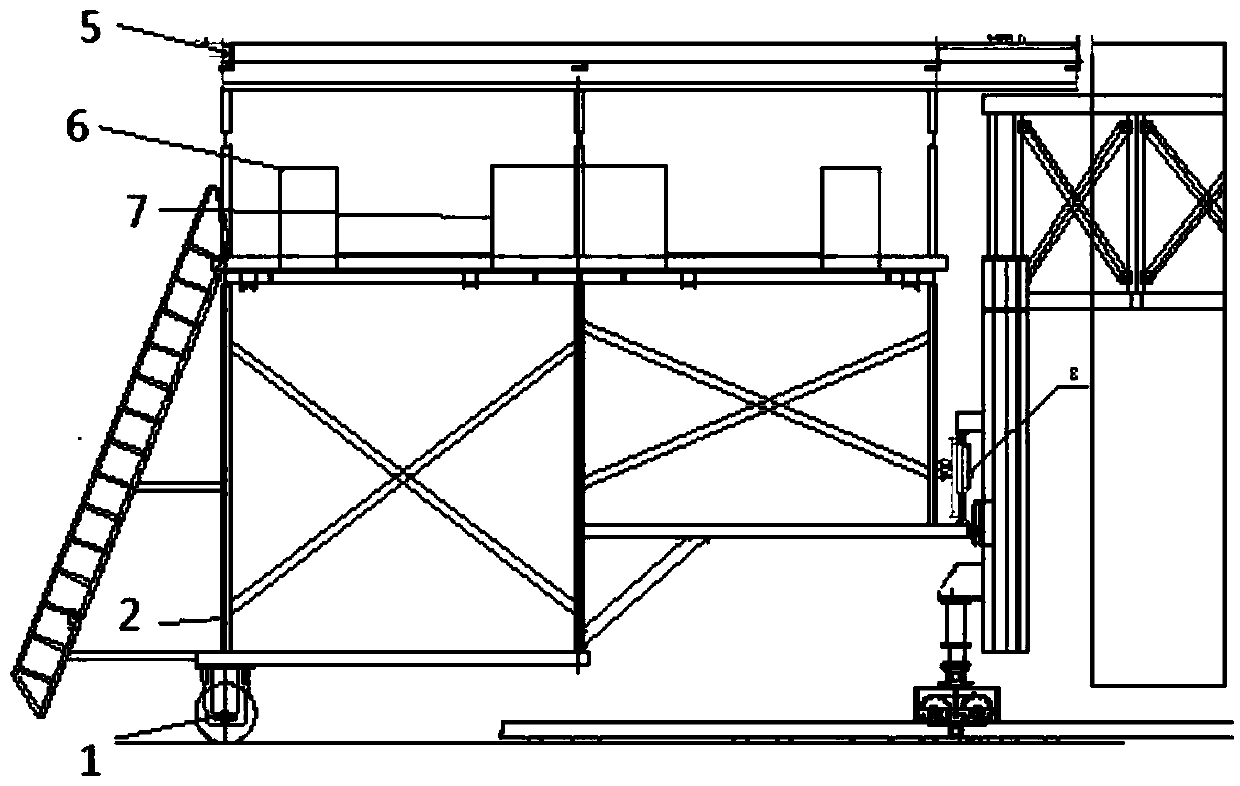

[0025] The present invention is an automatic steam curing system for the second lining concrete of a single-line tunnel, such as figure 1 with figure 2 As shown, it includes an arch frame 3 that is used to be placed in the tunnel and is consistent with its direction and arch shape. There is a space between the arch frame 3 and the side wall of the tunnel. An insulating rubber plate 5 is arranged on the annular surface of the arch frame 3 . Both ends of the frame 3 are provided with rubber curtains, and the thermal insulation rubber plate 5 and the rubber curtains form a cavity with an upper opening. A closed space is formed between the two linings; the lower end of the arch 3 is also closed by a rubber cord. On the arch 3 and in the cavity, there are a plurality of vertically arranged steam pipes 8 arranged at intervals in the circumferential direction. A plurality of steam outlets are arranged at intervals along its direction, and the steam outlets are used to spray water v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com