Engine oil collector and oil sump assembling device and assembling method thereof

An oil collector and engine oil technology, which is applied in the direction of engine components, machines/engines, and engine lubrication, can solve the problems of large space occupation, poor flexibility, and slow working efficiency of turning machines, so as to improve the utilization rate, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

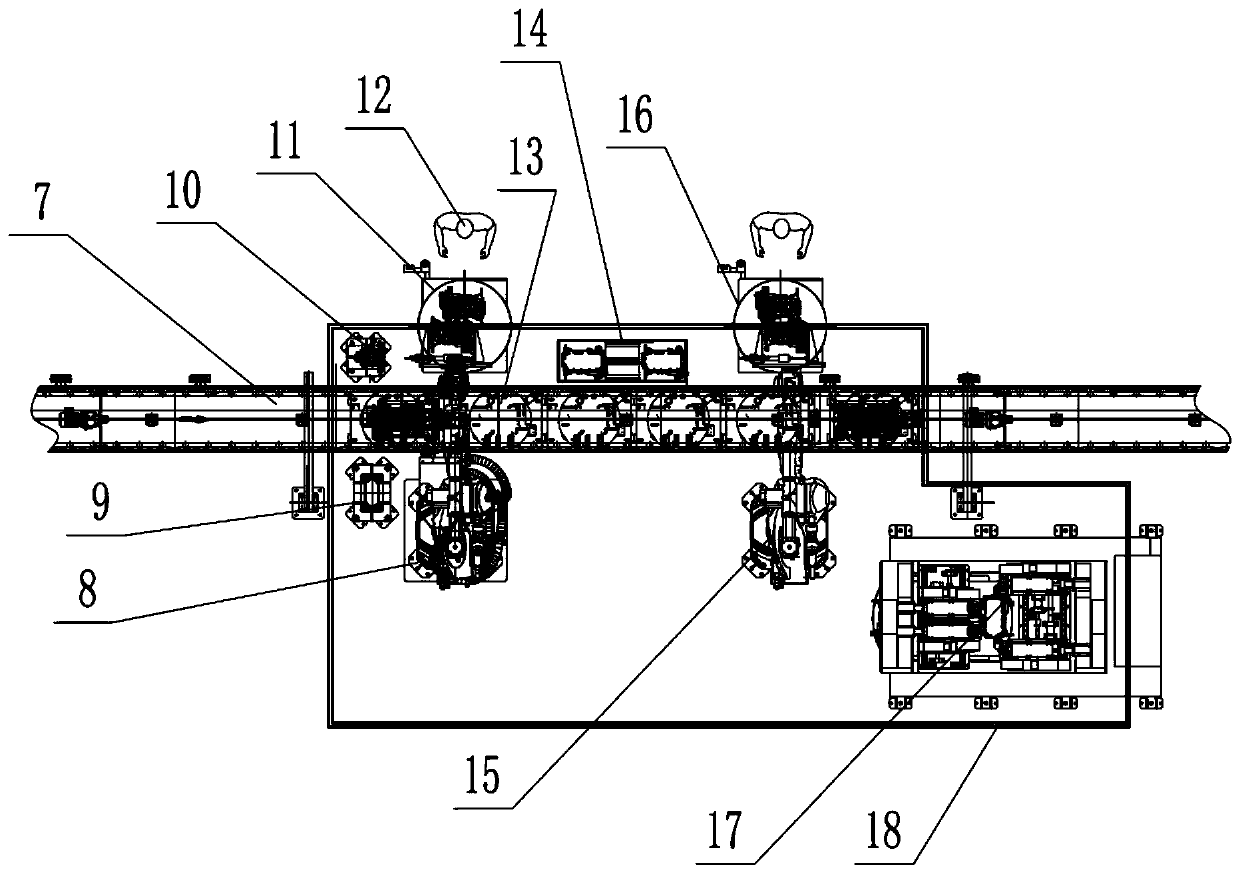

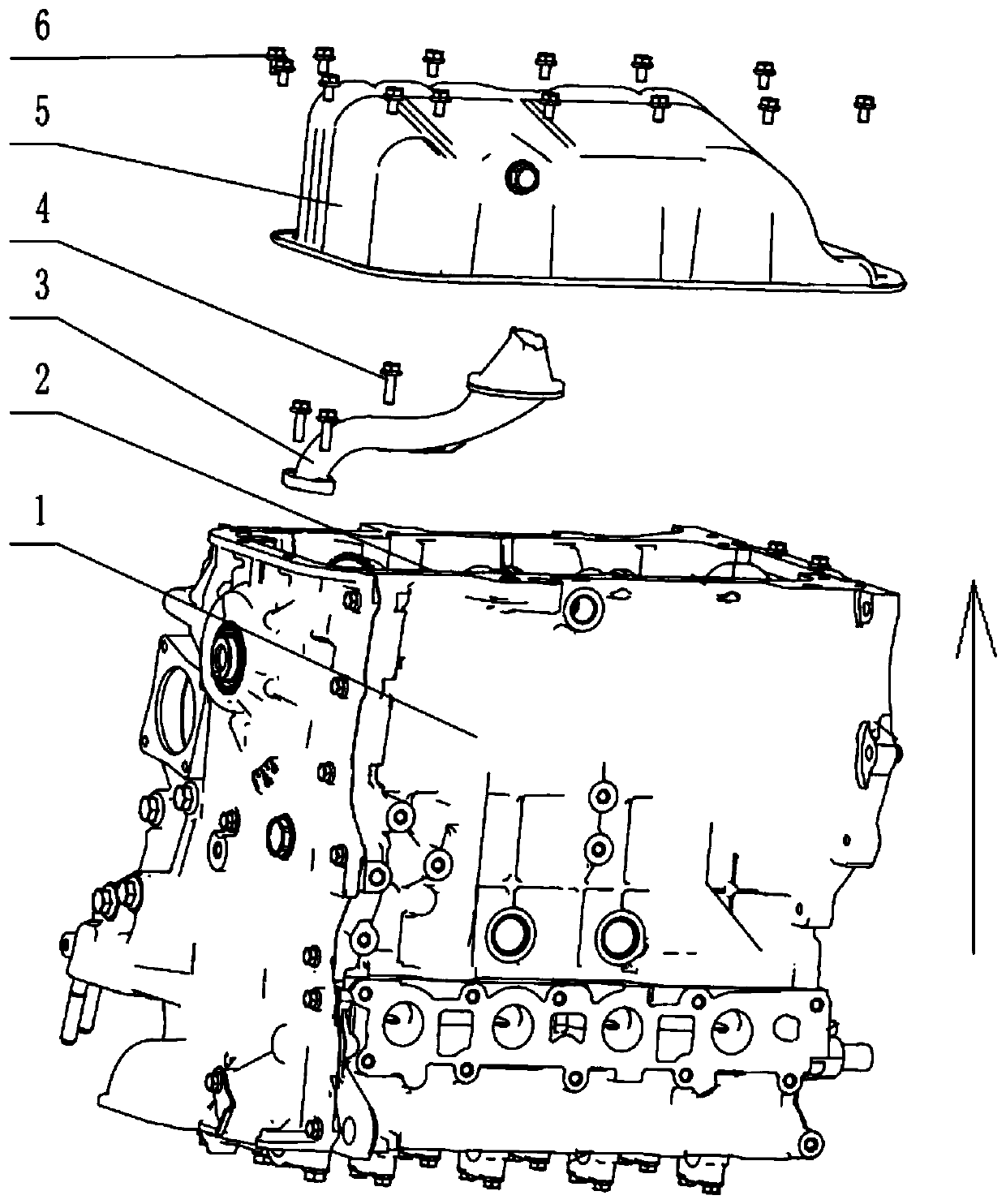

[0039] see figure 1 , an engine oil collector and oil pan assembly device, has:

[0040] Assembly line body, the assembly line body can transport the engine;

[0041] The oil collector sub-assembly turntable is set on one side of the assembly line body, and the operator can install the oil collector on the oil collector sub-assembly turntable;

[0042] The sliding shuttle table is set on one side of the assembly line body; the engine can apply glue on the sliding shuttle table;

[0043] The robot glue applicator is installed on one side of the assembly line body. The robot glue applicator can clamp the engine on the assembly line body and turn over the engine; the robot glue applicator can grip the engine to the oil collector, subpac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com