Automatic error correcting control method and device and electrical equipment

An automatic error correction and control method technology, applied in mechanical equipment, lighting and heating equipment, heating and ventilation control systems, etc. The effect of anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

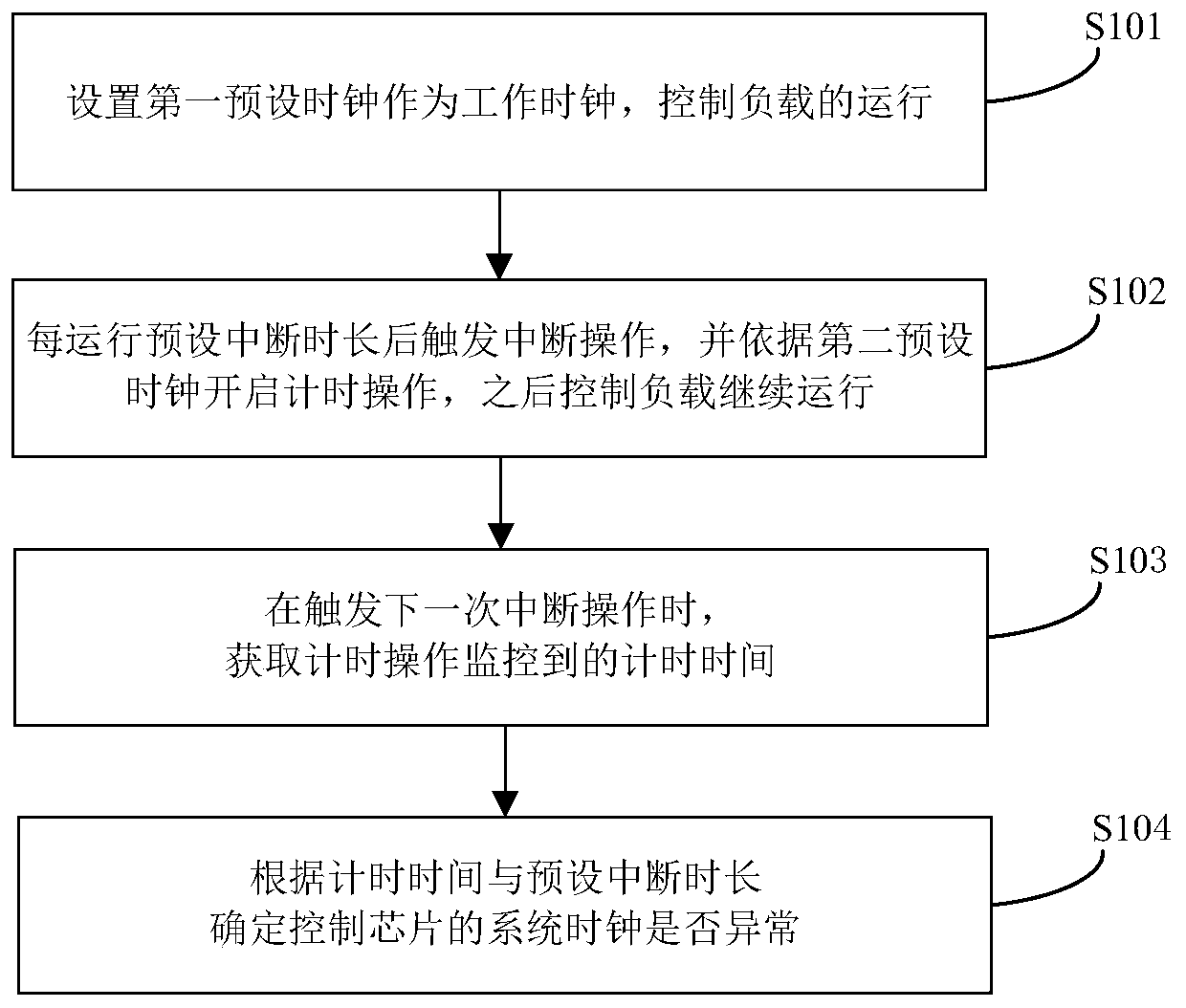

[0026] figure 1 is a flowchart of an automatic error correction control method according to an embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

[0027] Step S101, setting the first preset clock as the working clock to control the operation of the load;

[0028] Step S102, triggering the interrupt operation after each preset interrupt duration, and starting the timing operation according to the second preset clock, and then controlling the load to continue running;

[0029] Step S103, when the next interrupt operation is triggered, obtain the timing time monitored by the timing operation;

[0030] Step S104, determining whether the system clock of the control chip is abnormal according to the timing time and the preset interrupt duration.

[0031] This embodiment provides a safe and controllable automatic error correction control scheme, which can effectively monitor whether the system clock of the control chip is norm...

Embodiment 2

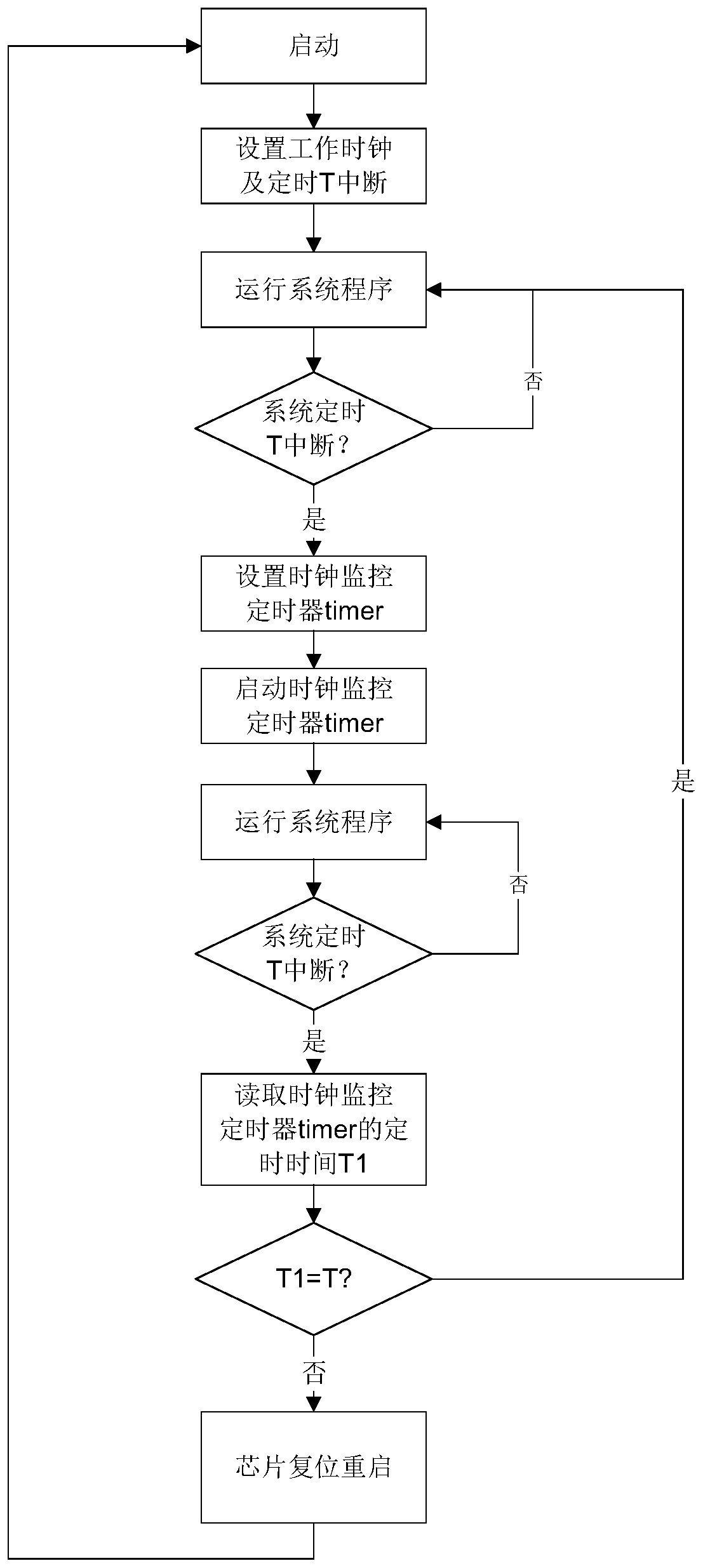

[0036] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. figure 2 is an automatic error correction control flow chart of the air conditioner according to an embodiment of the present invention, such as figure 2 As shown, the process includes:

[0037] Step 1: The air conditioner control chip starts to work.

[0038] Step 2: The air conditioner control chip executes the initialization program, and provides the original clock source to each functional module inside the control chip after frequency multiplication and frequency division as a working clock. Set the timing T (that is, the above-mentioned preset interrupt duration), that is, execute the interrupt subroutine every interval T.

[0039] Step 3: Run the system program according to the working clock set in Step 2 to control the operation of the air conditioner load.

[0040] Step 4: Determine whether to trigger t...

Embodiment 3

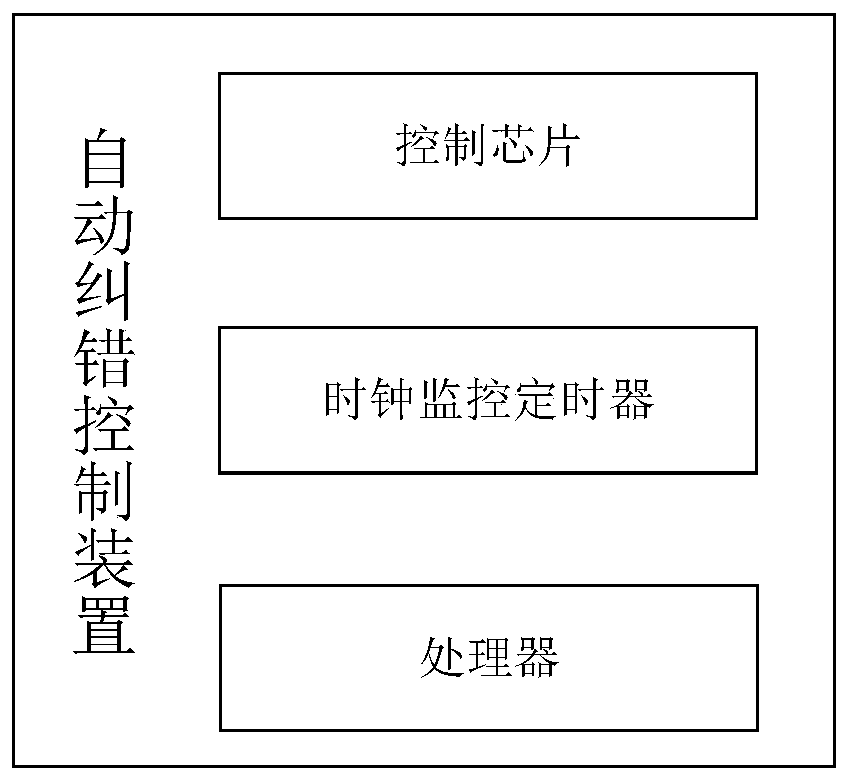

[0050] corresponds to figure 1 The automatic error correction control method introduced, this embodiment provides an automatic error correction control device, such as image 3 The structural block diagram of the automatic error correction control device shown, the device includes:

[0051] The control chip is used to set the first preset clock as the working clock to control the operation of the load; it is also used to trigger the interrupt operation after each preset interrupt duration;

[0052] The clock monitoring timer is used to start the timing operation according to the second preset clock when the control chip triggers the interrupt operation;

[0053] The processor is used to acquire the timing time monitored by the clock monitoring timer between two interrupt operations, and determine whether the system clock of the control chip is abnormal according to the timing time and the preset interrupt duration.

[0054] This embodiment provides a safe and controllable au...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com