Cement concrete joint filler anti-permeability test method

A technology of cement concrete and experimental methods, which is applied in the direction of permeability/surface area analysis, suspension and porous material analysis, and measuring devices, etc., which can solve problems such as large errors and inaccurate measurement of water seepage of joint fillers, and achieve experimental operation Effects in simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following is further described in detail through specific implementation methods:

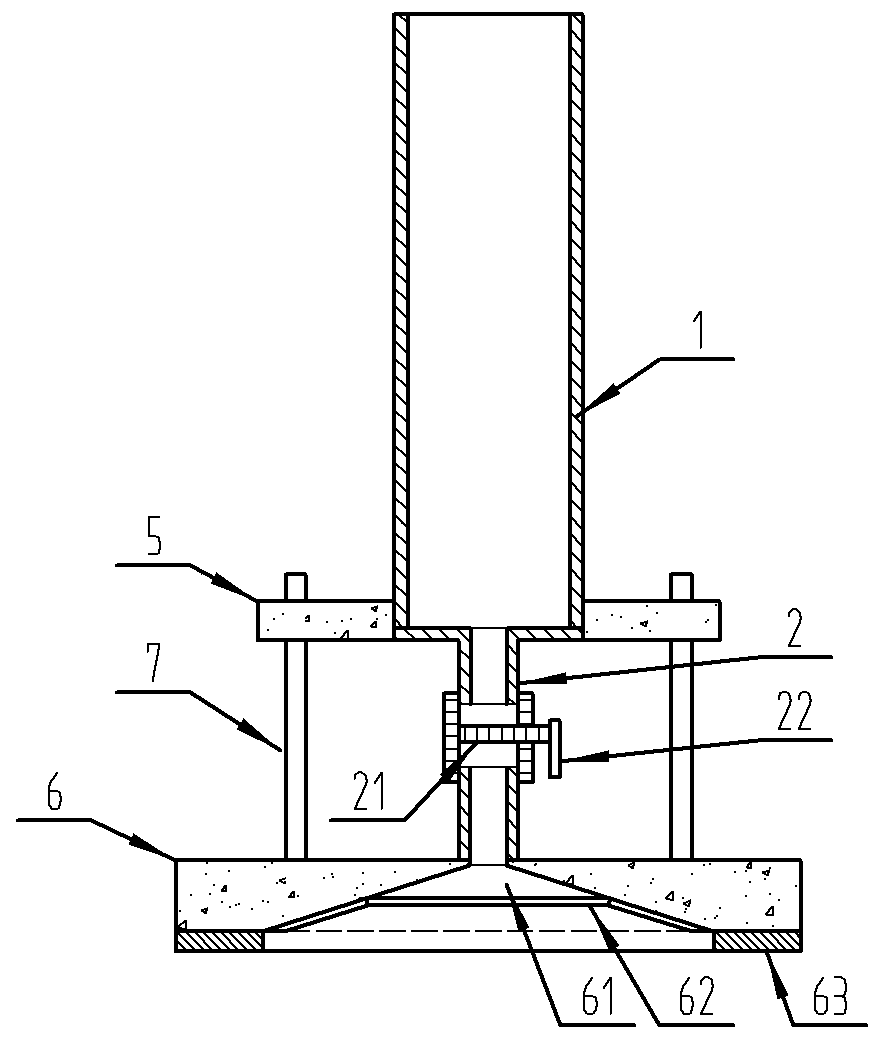

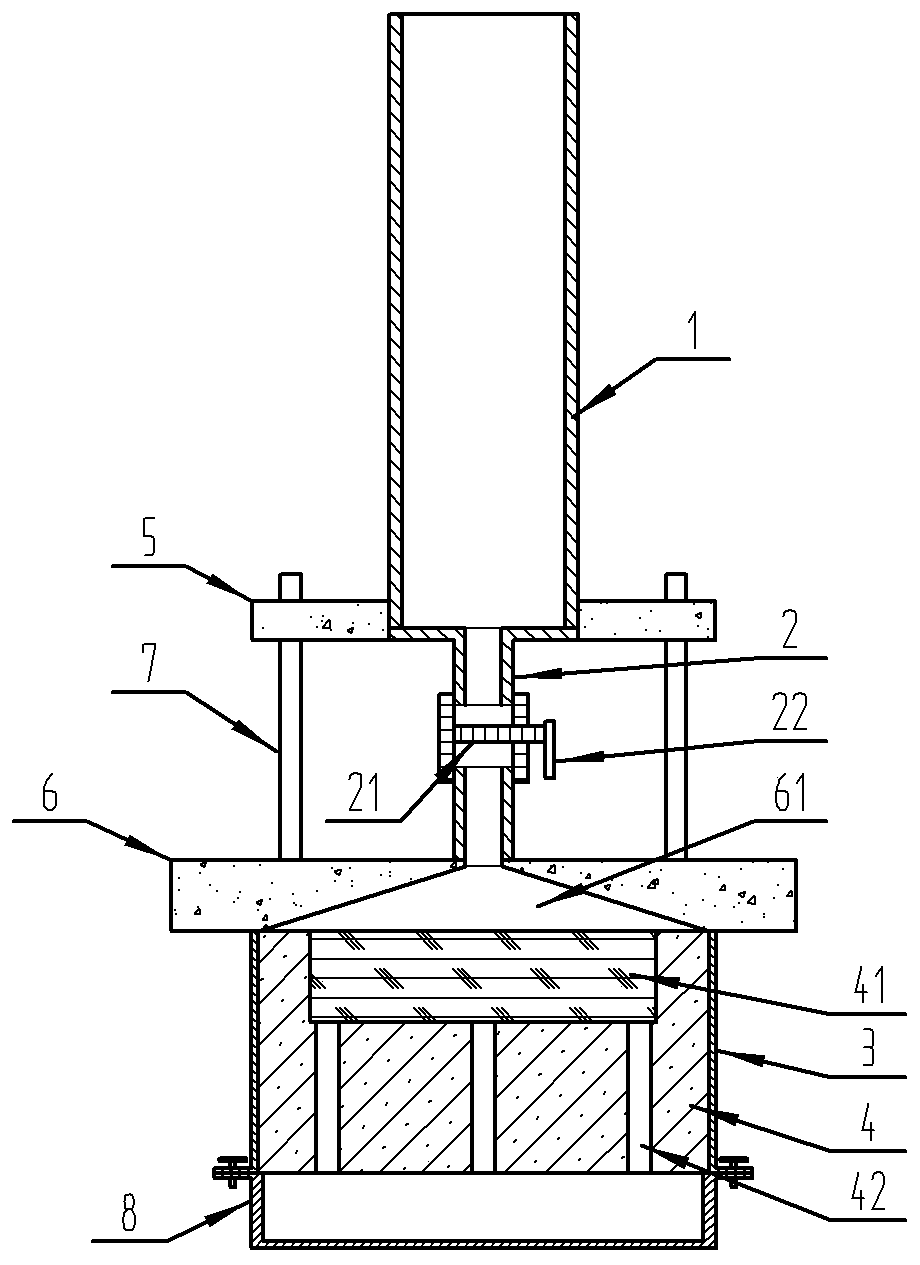

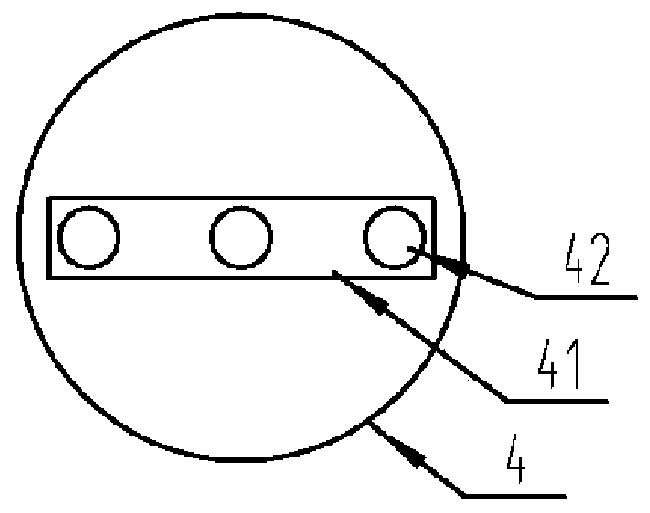

[0038] The reference signs in the drawings of the description include: measuring cylinder 1, conduit 2, valve 21, handle 22, cylinder 3, test piece 4, joint filler 41, leak hole 42, top plate 5, base 6, cavity 61, seal Ring 62, sealing material 63, vertical column 7, water container 8.

[0039] like figure 2 and image 3 As shown, the cement concrete joint filler 41 anti-seepage test method is tested through an indoor water seepage meter.

[0040] The indoor water seepage meter includes a measuring cylinder 1, a conduit 2, a base 6, a cylindrical cylinder 3 with openings at both ends, and a test piece 4. The conduit 2 is provided with a valve 21, and one end of the valve 21 is provided with a handle 22. The internal capacity of the graduated cylinder 1 is 600ml, and the material of the graduated cylinder 1 is transparent organic glass. The upper end of the cylindrical tube 3 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| sand rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com