Nonlinear dynamics analysis method for rotor-bearing system

A technology of nonlinear dynamics and analysis method, applied in the field of rotor-bearing system nonlinear dynamics analysis, which can solve problems such as errors and achieve accurate response calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

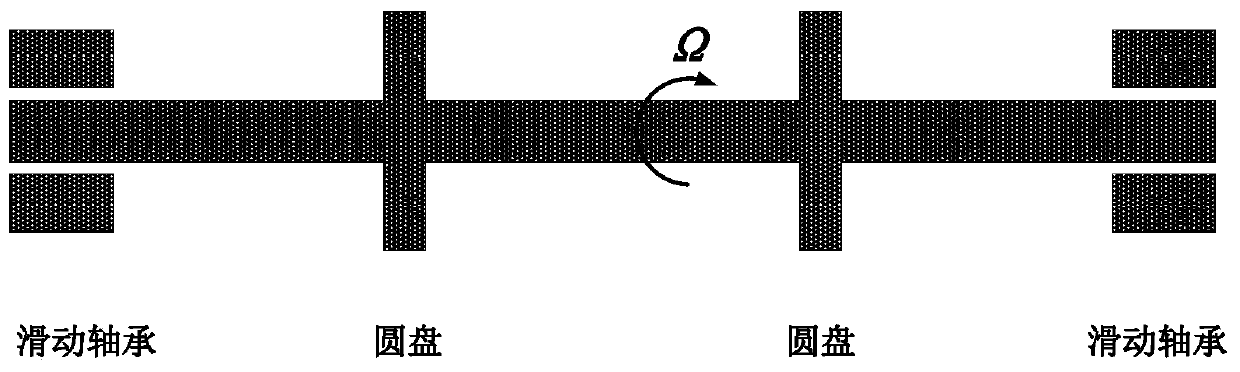

[0064] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0065] The present invention includes:

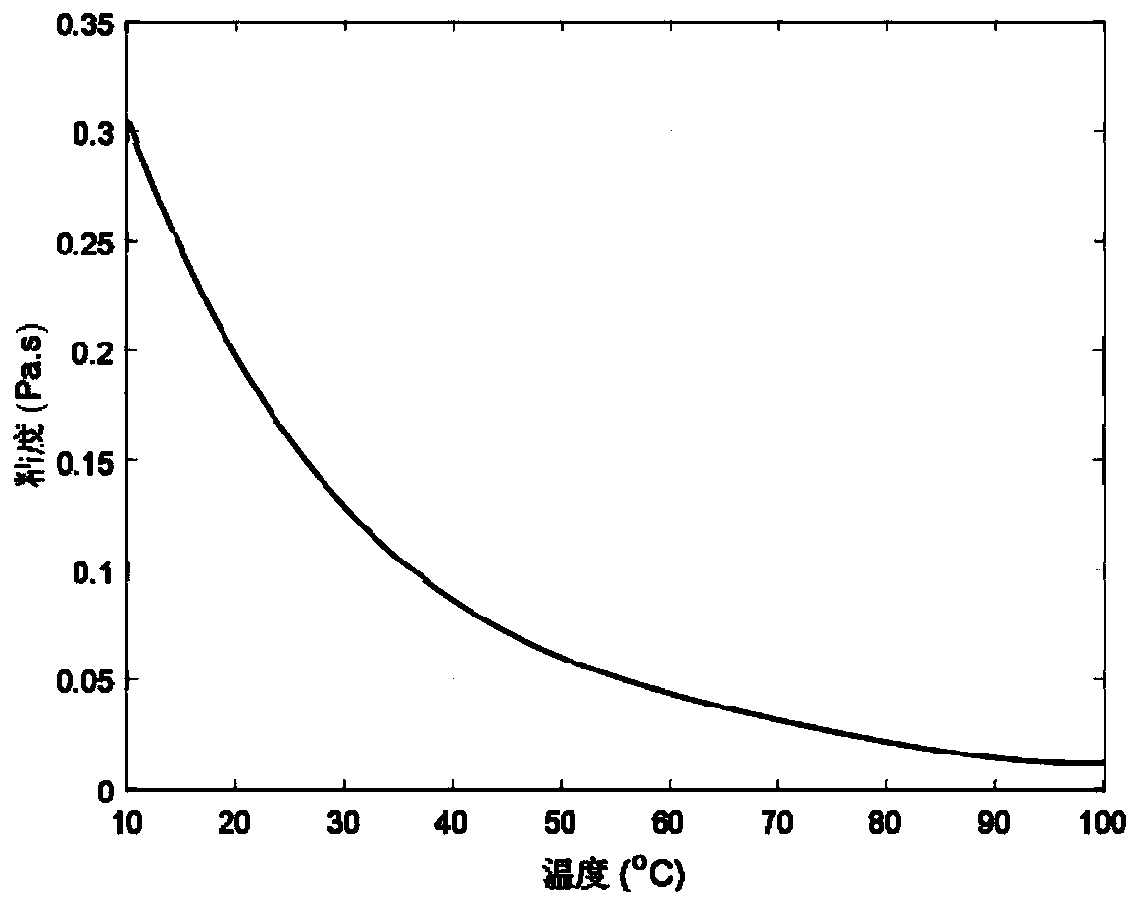

[0066] Step 1: Input calculation parameters, including: rotor length, rotor diameter, rotor material parameters, speed, disc length and thickness, disc diameter, disc material parameters, bearing width, bearing diameter, bearing radius clearance, lubricating oil viscosity, lubrication Oil density, oil inlet temperature.

[0067] Step 2: Calculate the overall mass matrix, stiffness matrix, damping matrix and gyro effect matrix of the system.

[0068] Step 3: Calculate the unbalanced excitation of the rotor.

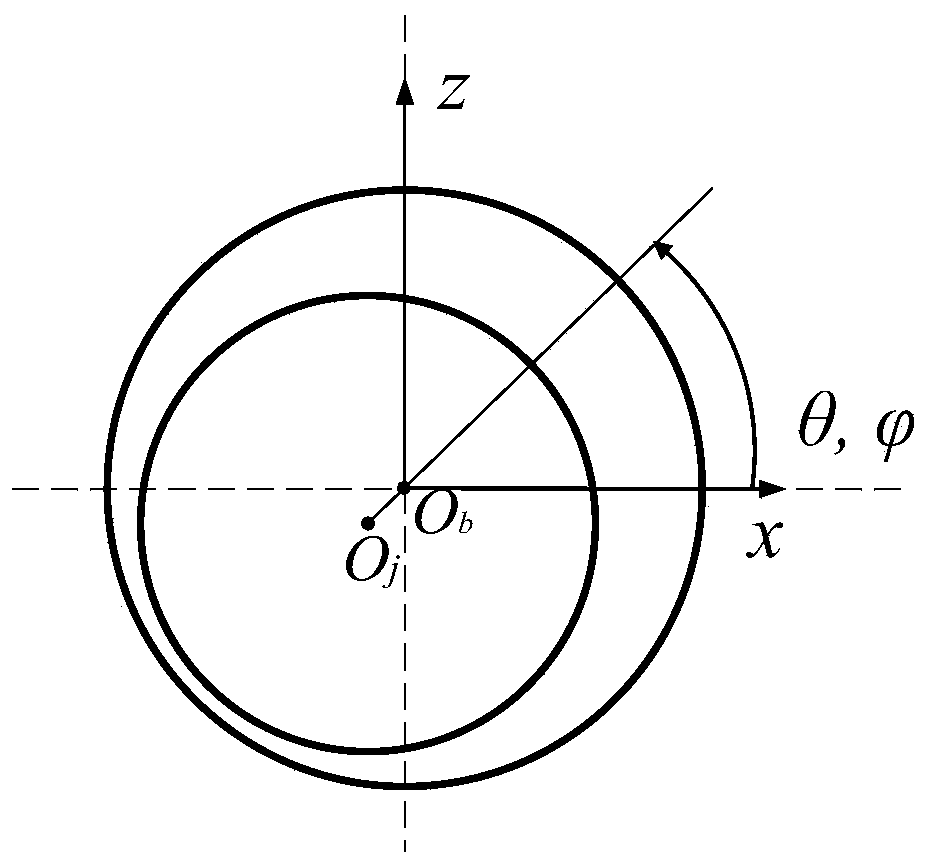

[0069] Step 4: Calculate the bearing oil film thickness at time t.

[0070] Step 5: Calculate the bearing oil film pressure at time t. Determine whether the oil film pressure satisfies the convergence condition, and if so, proceed to the next step of calculation; if not, return to step 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com