method for diagnosing the damage degree of a bearing under different working conditions based on a GS-SVM

A technology of bearing damage and diagnosis method, which is applied in the direction of mechanical bearing testing, instrumentation, calculation, etc., can solve the problem that the impact signal is difficult to be extracted, and achieve the effects of short calculation time, high efficiency, and avoiding impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

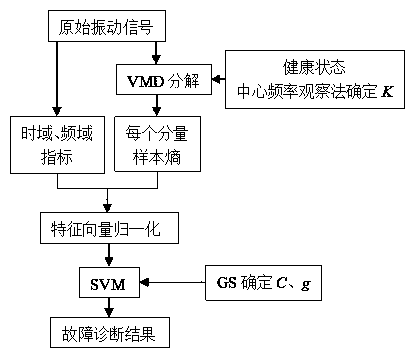

[0035] refer to figure 1 , a GS-SVM-based method for diagnosing the degree of bearing damage under different working conditions of the present invention specifically includes the following steps.

[0036] Step S1: Build a rotating machinery test bench, set the inner ring fault of the bearing of the output shaft, and identify it as a weak fault, a moderate fault, and a serious fault according to the size of the bearing damage. Use the acceleration sensor to collect the vibration signal of the gearbox bearing seat, the sampling frequency is f s The frequency is 12000Hz, and the total sampling points are 4096 points. In order to more fully fit the vibration signal of bearing damage under actual working conditions, 4 different bearing states are used for data collection at 0Hp, 1Hp, 2Hp, and 3Hp respectively, including health status, weak bearing faults, moderate bearing faults, and severe bearing faults 40 sets of data each, 10 sets of different loads in each state, a total of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com