Method for impregnating graphite by using polytetrafluoroethylene

A technology of polytetrafluoroethylene and impregnated graphite, which is applied in the chemical industry, can solve problems such as poor temperature resistance, achieve the effect of improving corrosion resistance and high temperature resistance, and broadening the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

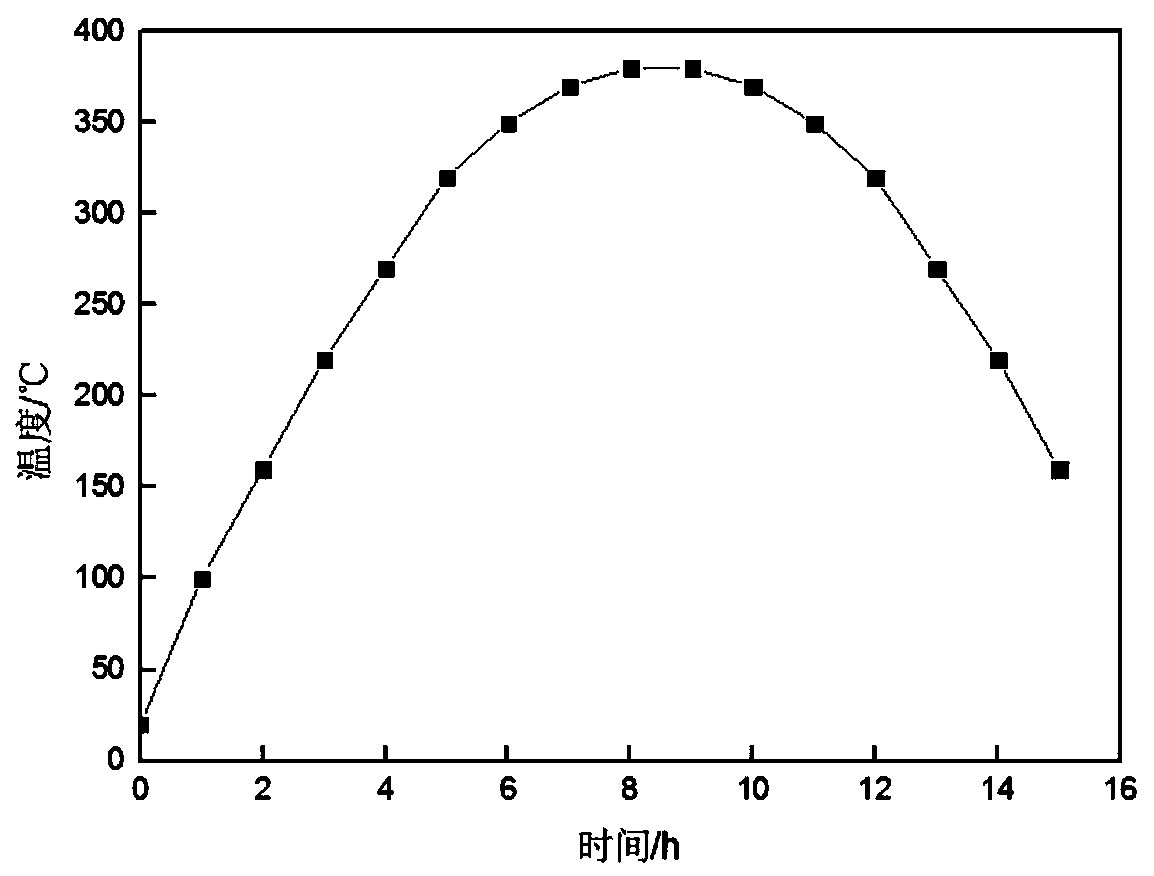

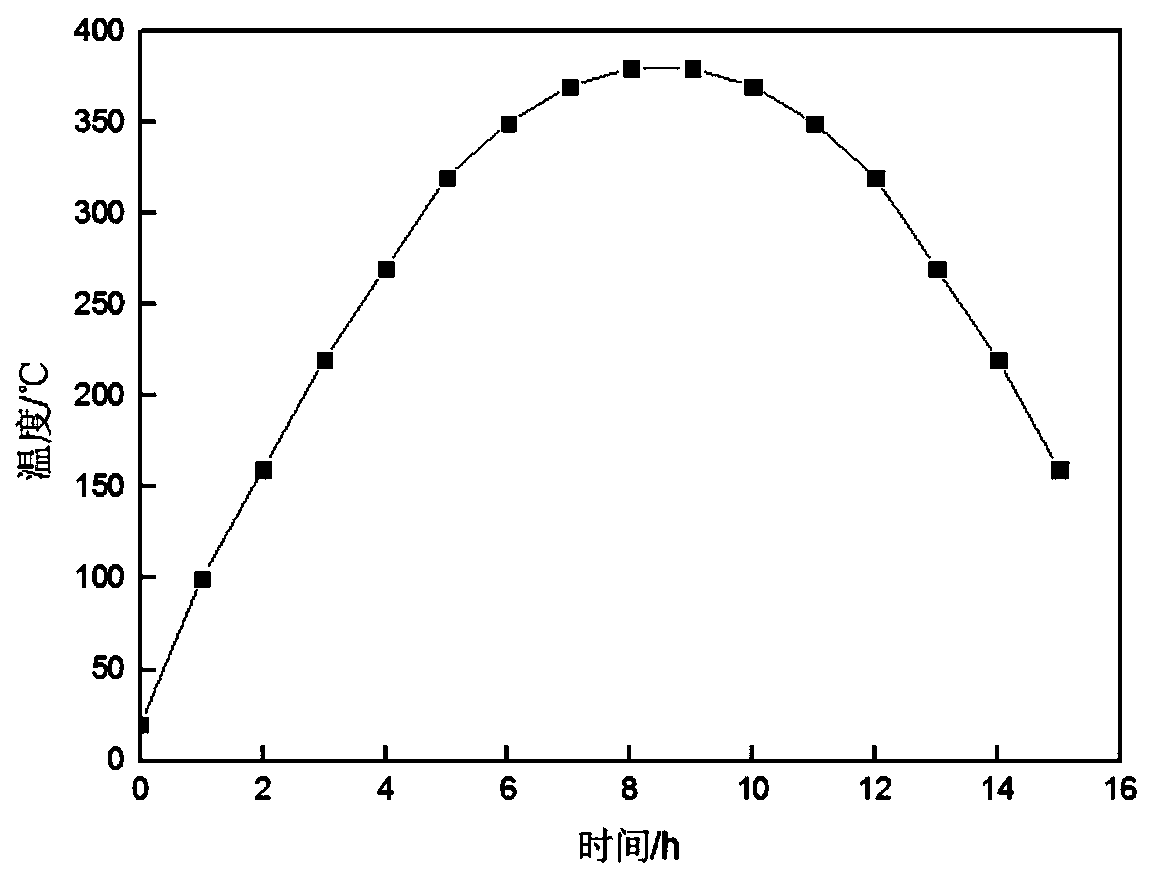

[0019] Embodiment: a kind of method and production technology thereof of polytetrafluoroethylene impregnated graphite, comprise the steps:

[0020] (1) Pretreatment of the graphite material: clean the surface of the graphite sample, dry it in a drying oven (120° C.) to a constant weight and then cool it to room temperature;

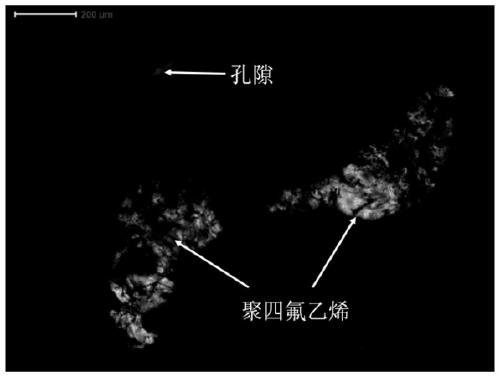

[0021] (2) The first impregnation of graphite material: put the dried graphite material in the impregnation kettle, keep the distance between graphite materials at about 5mm, vacuumize to -0.08MPa at room temperature, keep the vacuum state for 4 hours, and use the negative pressure in the kettle to vacuum The polytetrafluoroethylene impregnating agent is sucked into the impregnation kettle, so that the level of the polytetrafluoroethylene impregnating liquid is 10mm-20mm higher than that of the graphite material. After 0.5h, the vacuum is removed, and the pressure in the kettle is increased to 0.7MPa, and the pressure is released after immersing for 5h. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com