Battery internal circulation heat management system

A thermal management system and battery technology, applied in secondary batteries, battery components, circuits, etc., can solve problems such as environmental pollution, waste of phase change materials, slow evaporation, etc., achieve huge heat transfer capacity and prolong service life Life, the effect of prolonging the working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

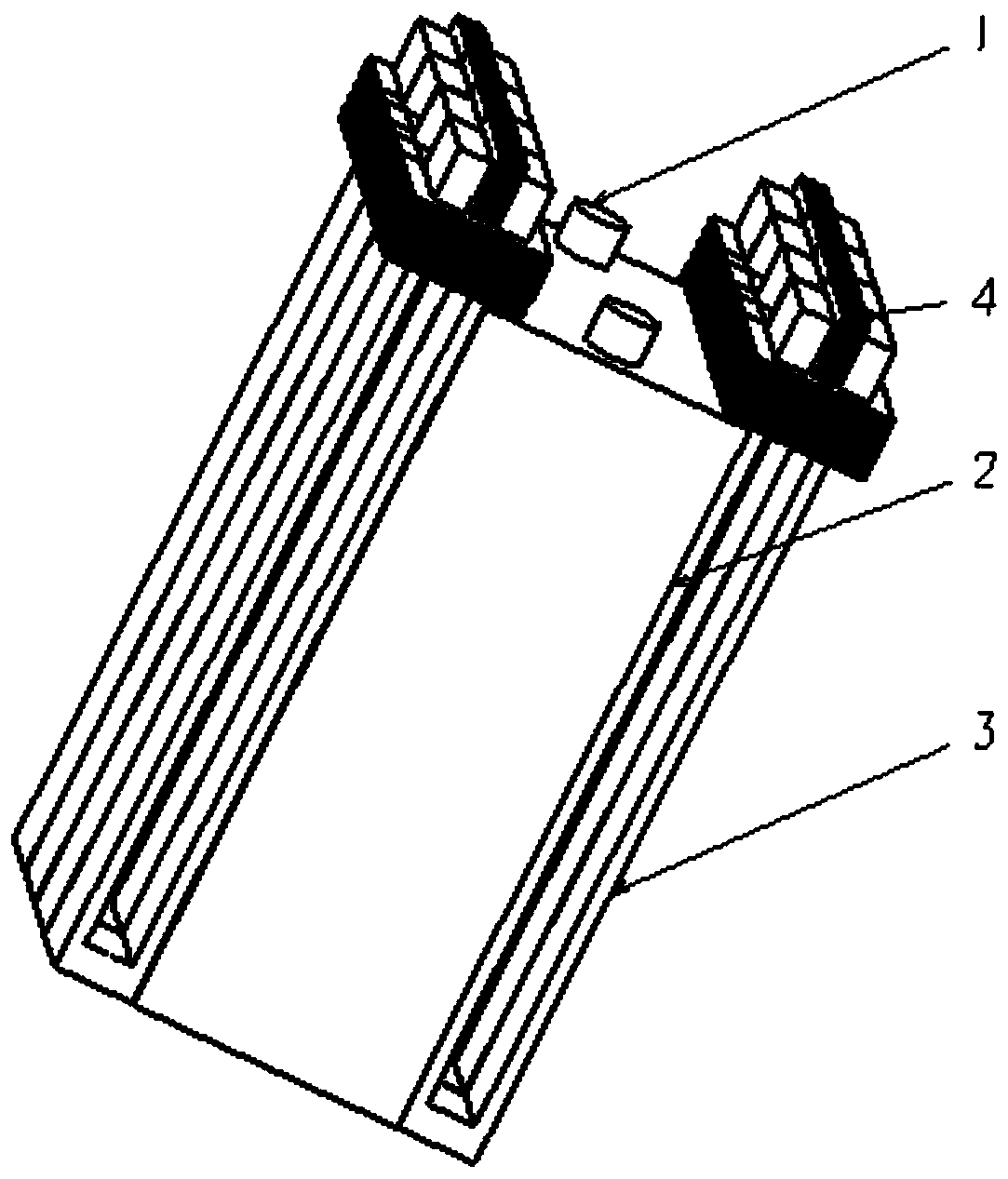

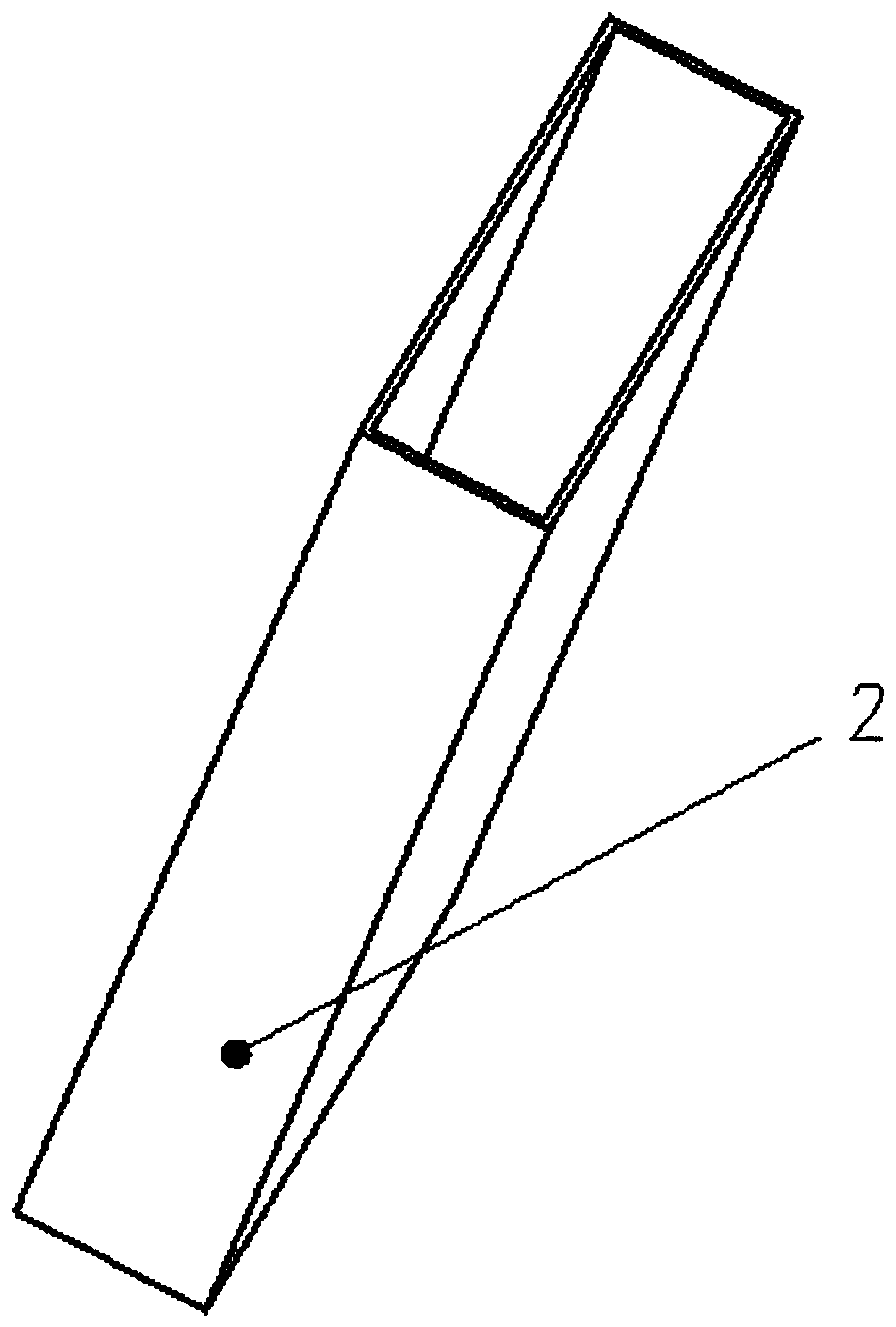

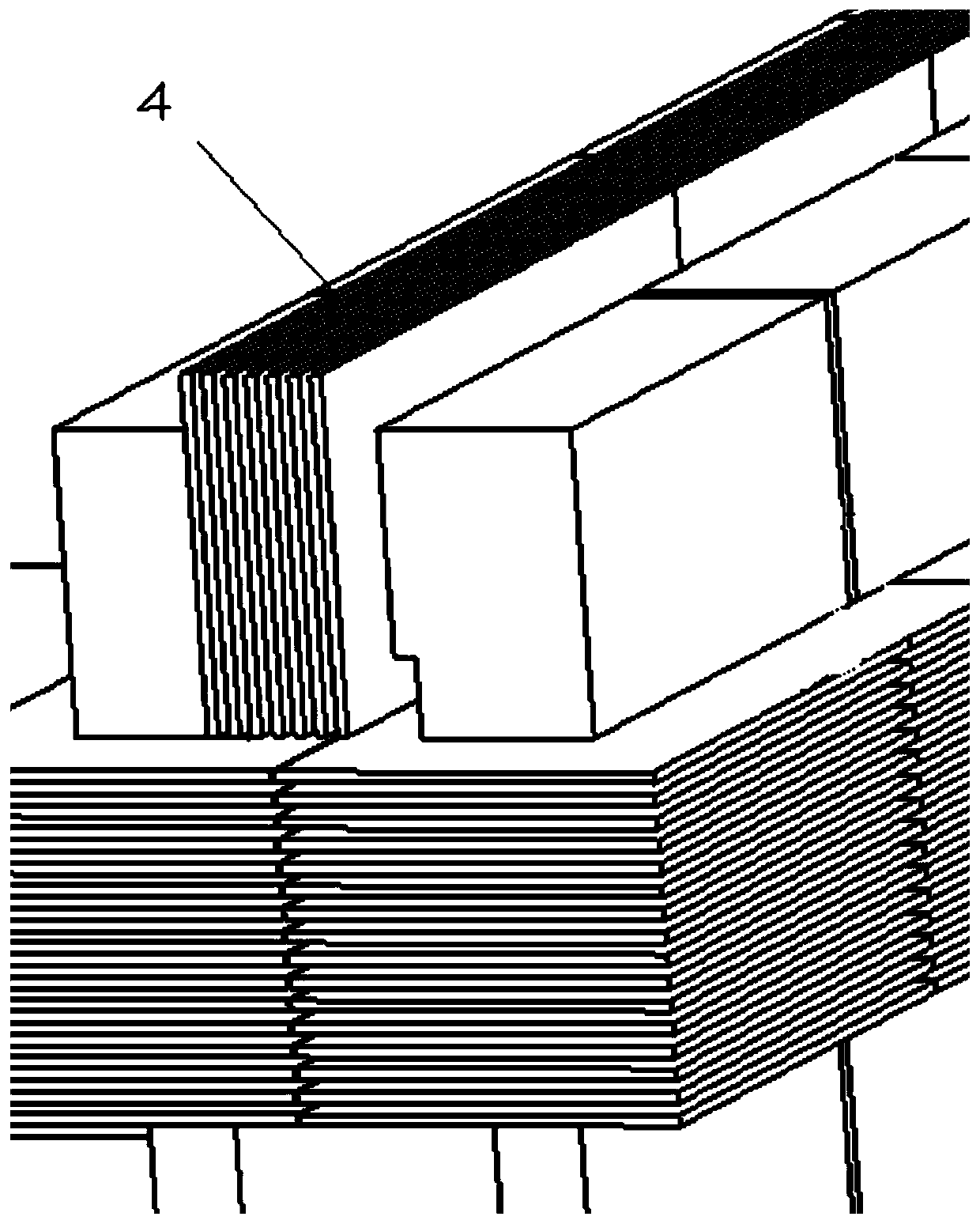

[0027] figure 1 It is a schematic diagram of the overall structure of the present invention, figure 2 is the schematic diagram of the structure of the graphene sleeve, image 3 is a partial enlarged schematic diagram of the structure of the fin, Figure 4 is the schematic diagram of the structure of the battery holder, Figure 5 is the schematic diagram of the structure of the insulation board, Image 6 It is a partial enlarged schematic diagram of the cross-section of the water-absorbing fiber, Figure 7 It is a schematic diagram of the cross pins for fixing the upper part of the water-absorbing fiber. As shown in the figure, the battery internal cycle thermal management system in this embodiment includes a graphene sleeve 2 attached to the surface of the battery 1 and a multi-layer sleeve set in the graphene sleeve 2. A group of annular thermal cycle pipes 3; the annular thermal cycle pipe 3 includes a liquid holding section, an endothermic evaporation section, a conden...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com