Linear motor position feedback device

A linear motor and feedback device technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of high temperature, dust, oil pollution, difficult installation, difficult production and other problems, and achieve great practical value and economy Benefits, guaranteed reliability and applicability, high anti-pollution level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

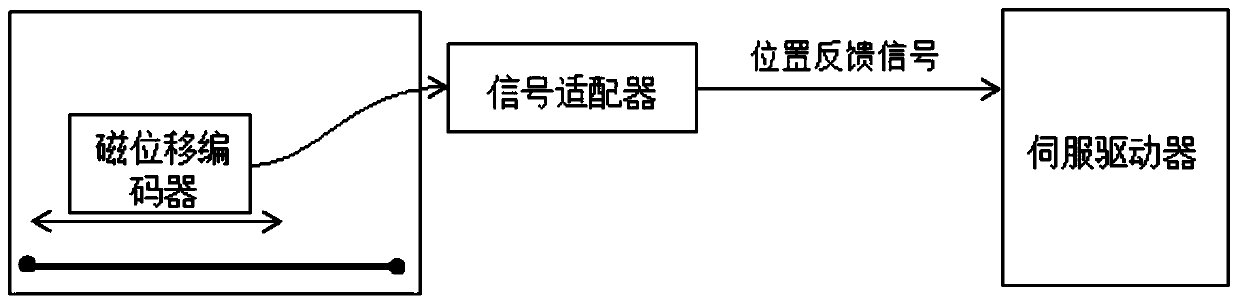

[0030] Such as figure 1 As shown, the linear motor position feedback device of the present invention includes a magnetic displacement encoder, a signal adapter and a connecting wire; the magnetic displacement encoder, the signal adapter and the servo driver are sequentially connected through a connecting wire.

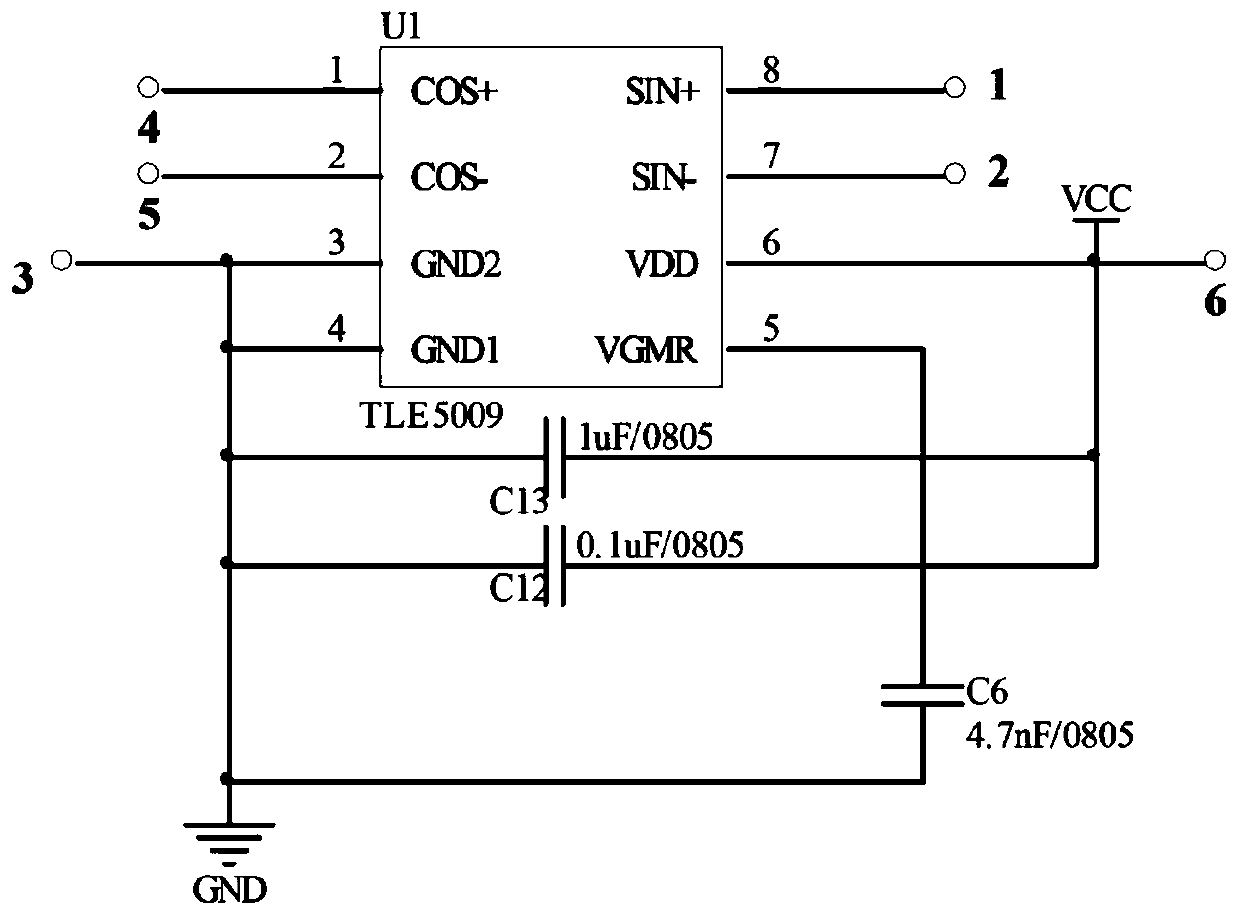

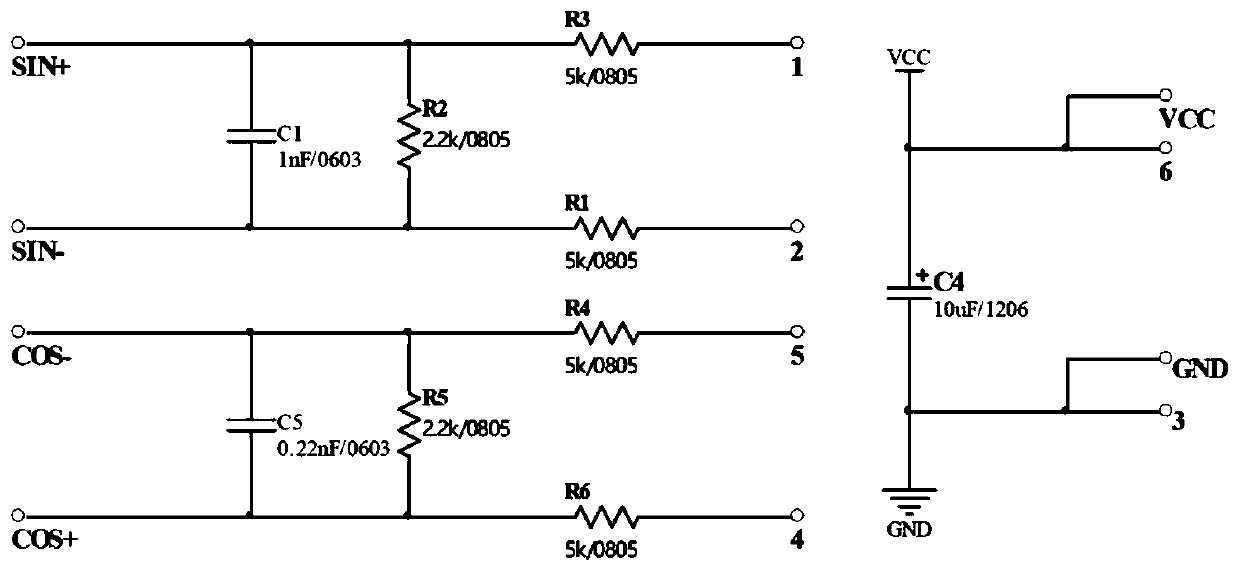

[0031] The magnetic displacement encoder is glued into the encoder mechanism, and the encoder mechanism is installed on the mover of the linear motor, and follows the movement of the mover to detect the change of the magnetic field of the stator of the linear motor in real time; Figure 2-3 As shown, the magnetic displacement encoder includes a first PCB board and a second PCB board inside, and the first PCB board and the second PCB board are respectively covered with a reluctance magnetic field detection circuit and an analog sin-cosine signal output circuit; the first PCB board A reluctance chip is integrated on the board to detect the magnetic field of the linear mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com