Extrusion device for 3D printing of chocolate

A 3D printing and chocolate technology, applied in the field of 3D printing, can solve problems affecting work efficiency, increase operation steps, etc., and achieve the effect of improving work efficiency, improving precision, printing accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means of the present invention and the technical effects that can be achieved more clearly and more perfectly disclosed, the following embodiments are provided hereby, and the following detailed descriptions are made in conjunction with the accompanying drawings:

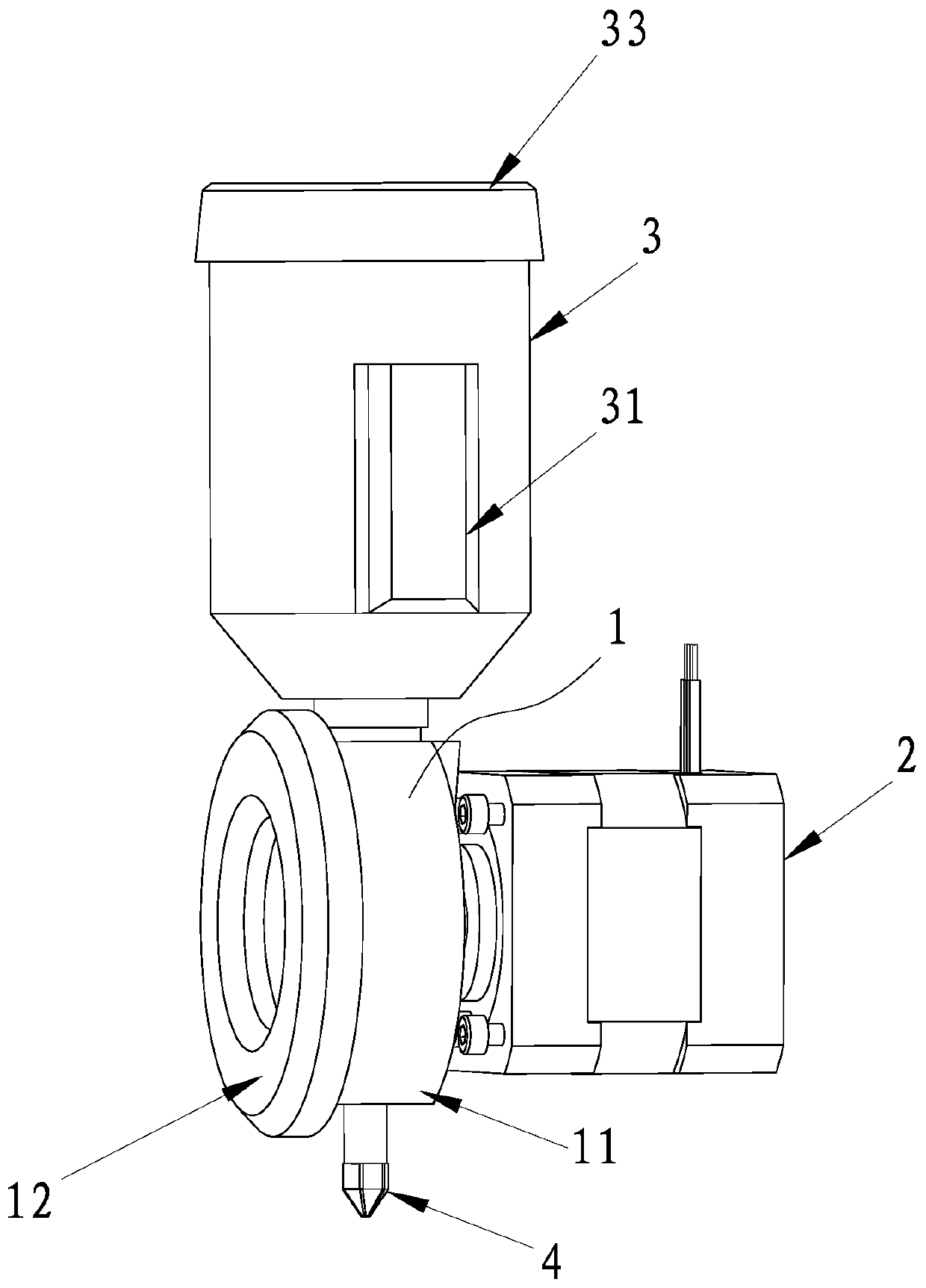

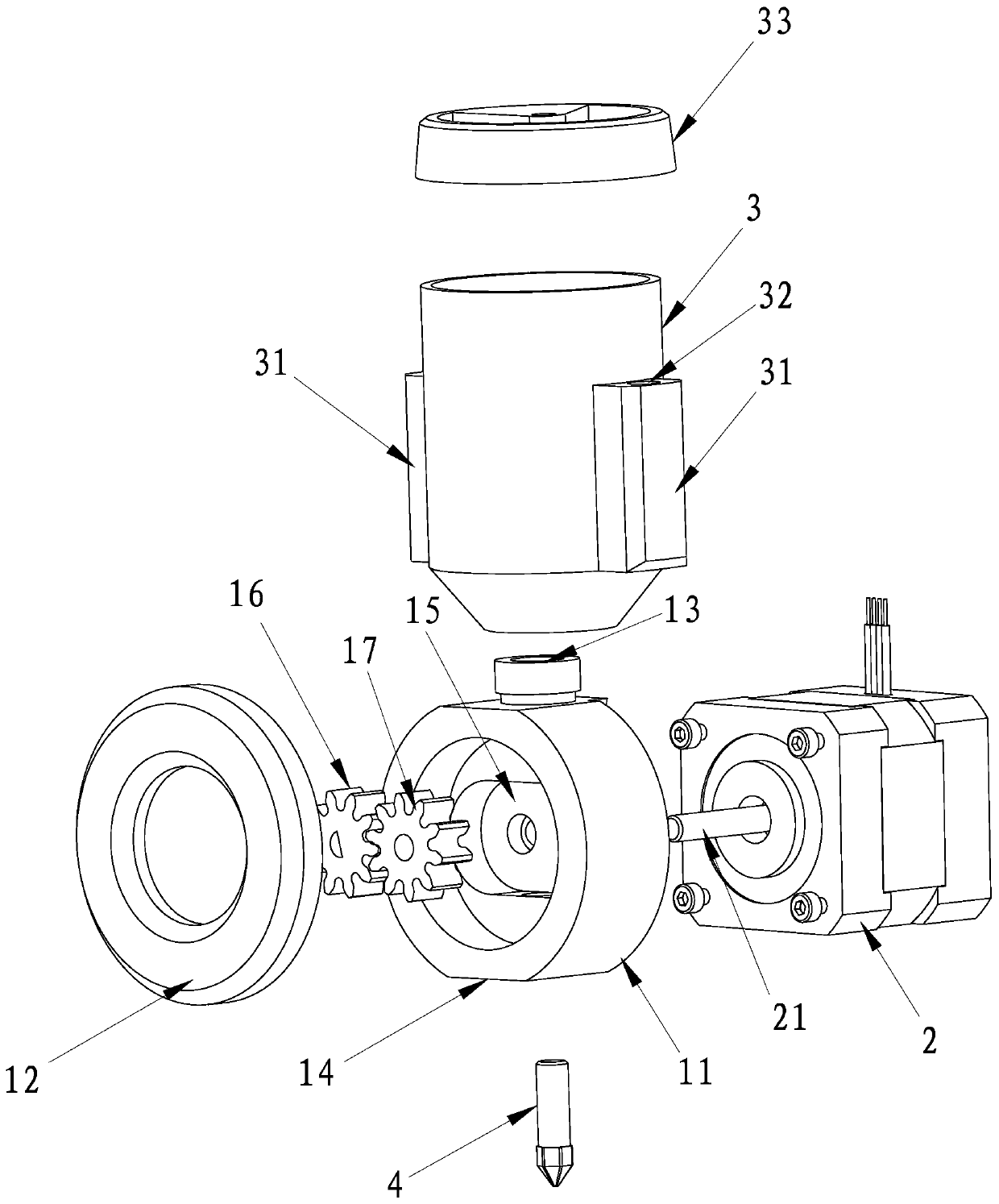

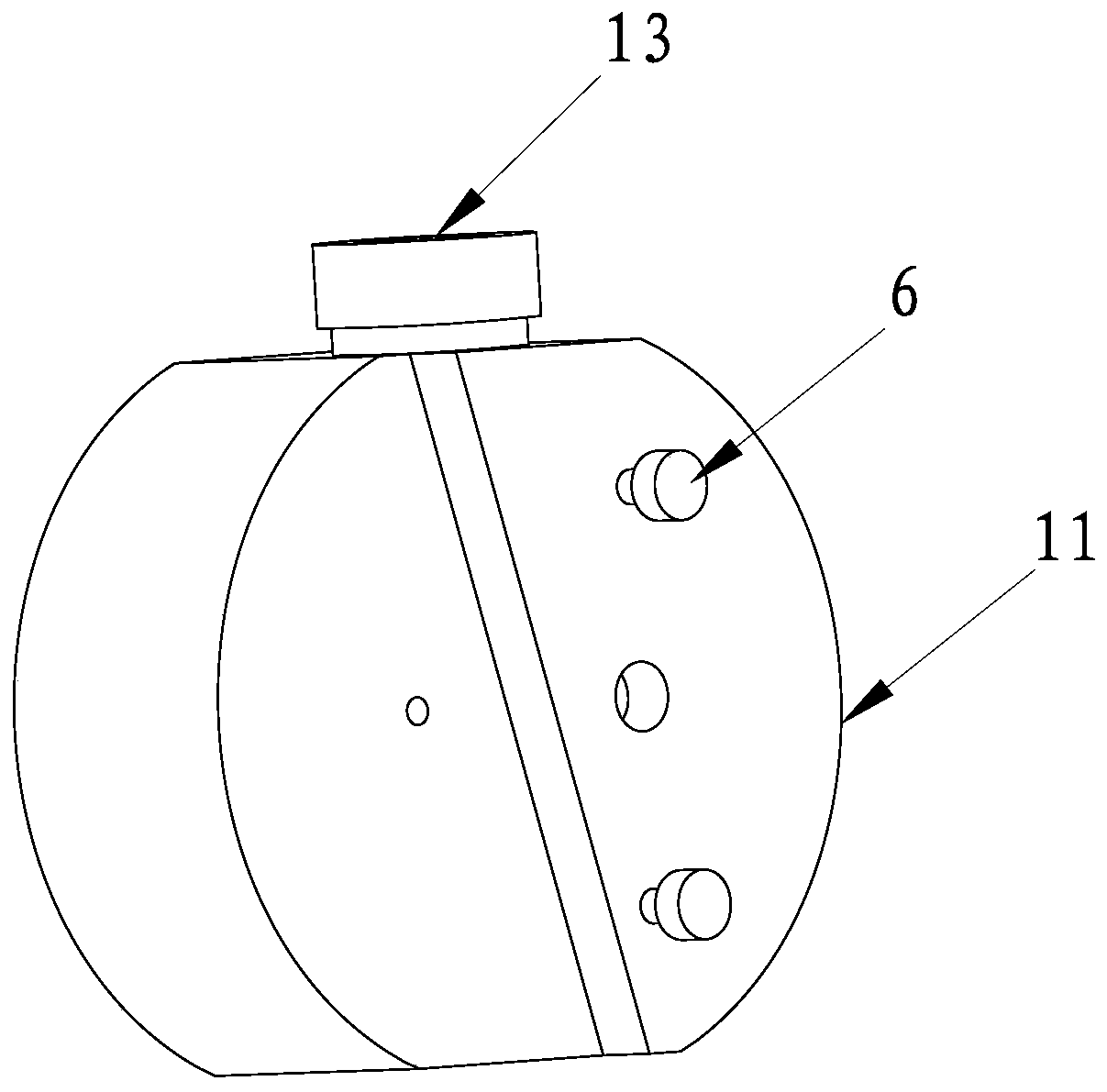

[0029] Chocolate 3D printing extrusion device, including a gear pump 1 with gears inside, a motor 2 connected to the gear pump 1, a feeding tank 3 and a nozzle 4 connected to and communicated with the gear pump 1, and the gear pump 1 is provided with a feeding port 13 and the discharge port 14, the feeding tank 3 is installed at the feed port 13, and the nozzle 4 is installed at the discharge port 14; the motor 2 drives the gear to rotate. The motor 2 drives the gear pump 1 to work, and the melted chocolate contained in the feeding tank 3 is sucked into the gear pump 1 from the feed port 13 , and then extruded from the nozzle 4 along the discharge port 14 . The gear pump 1 is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com