Positioning device and method for machining gland sealing arc segment in steam turbine

The technology of a positioning device and a positioning method, which is applied in the field of steam turbine parts, can solve the problem that the positioning device cannot meet the processing and positioning of various types of steam seal arcs, and achieve the effect of simple structure, low manufacturing cost and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

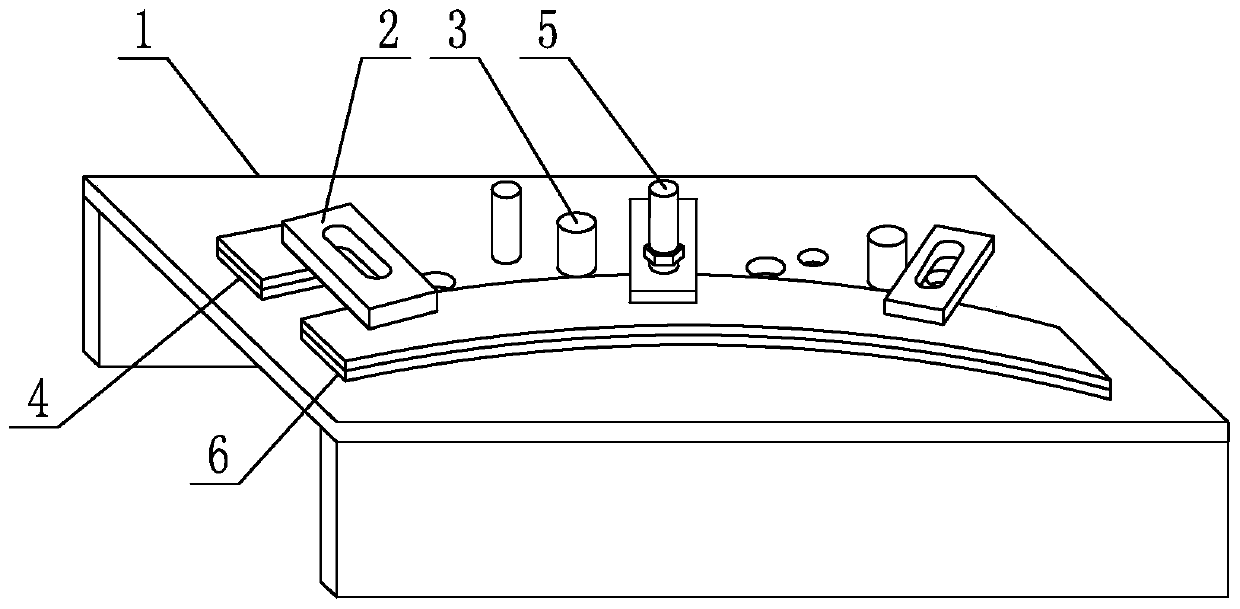

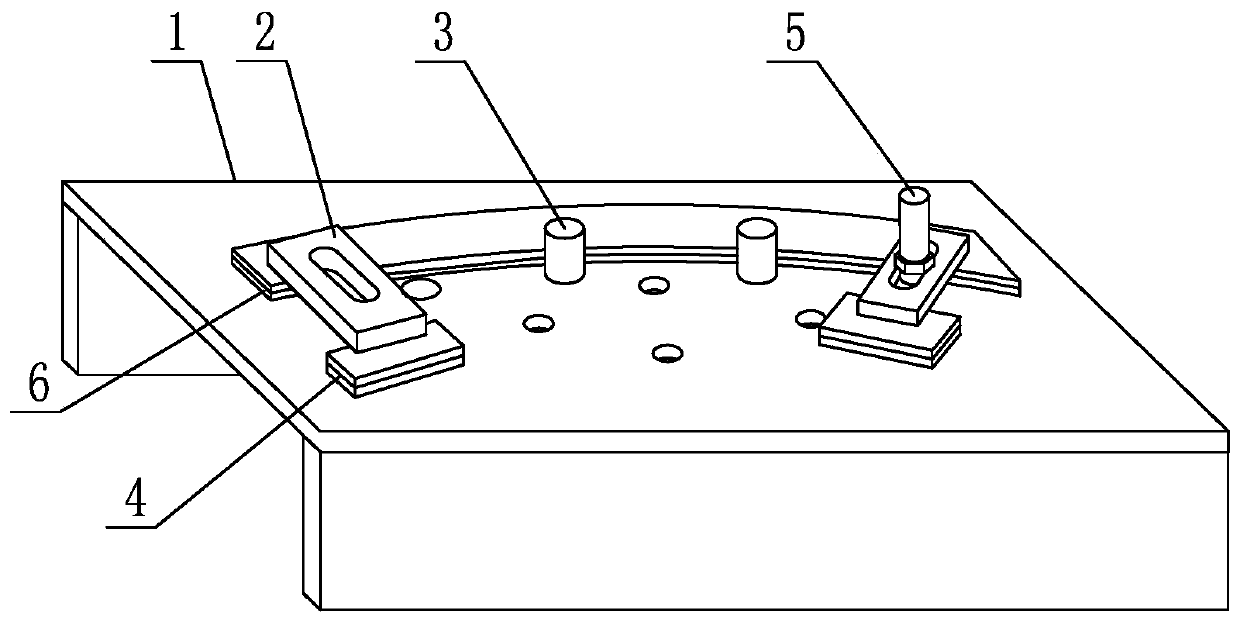

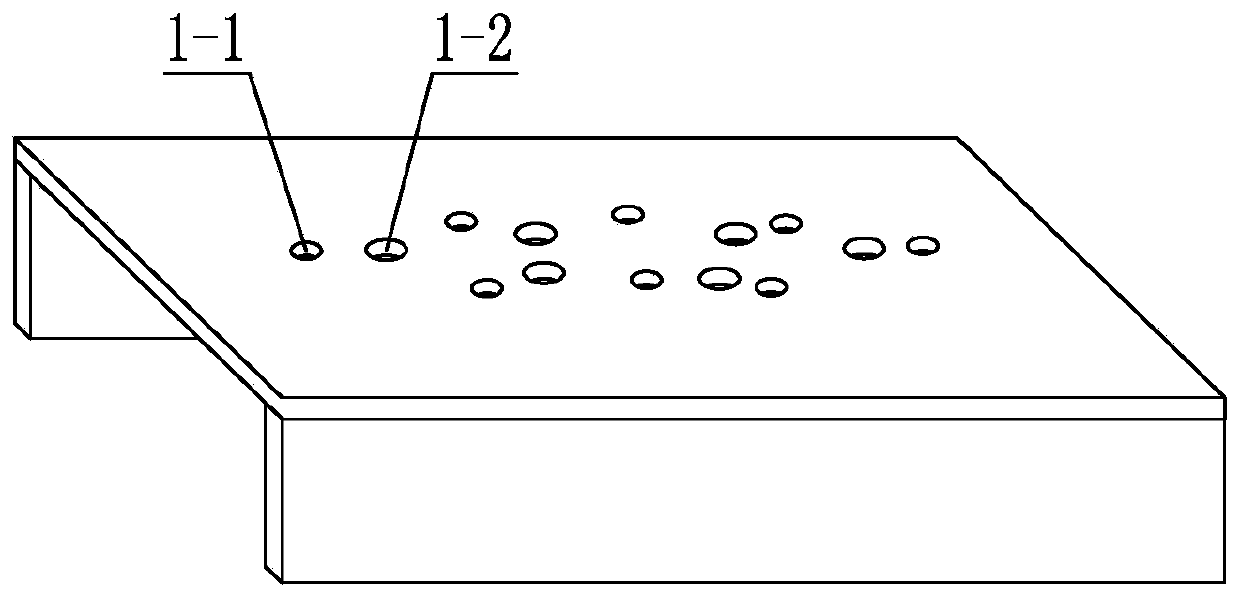

[0025] Specific implementation mode one: as figure 1 and figure 2 As shown, the positioning device described in this embodiment includes a workbench 1, a plurality of pressing plates 2, a plurality of positioning pins 3, a plurality of gaskets 4 and a plurality of compression bolts 5, such as image 3 As shown, there are a plurality of bolt holes 1-1 and a plurality of positioning holes 1-2 on the table of the workbench 1, and a plurality of bolt holes 1-1 and a plurality of positioning holes 1-2 are evenly distributed throughout the work On the table of platform 1, it is beneficial to the positioning and clamping of different types of steam seal arcs,

[0026] Such as Figure 5 As shown, in order to facilitate the adjustment of the position of the pressure plate, a long strip-shaped chute 2-1 is opened on the pressure plate 2 along the length direction of the pressure plate 2, and the pressure plate 2 is fixed and installed on the table top of the workbench 1 through the c...

specific Embodiment approach 2

[0030] Specific implementation mode two: as Image 6 As shown, a threaded column 3-1 is provided on one end surface of the positioning pin 3 described in this embodiment, and the threaded column 3-1 is screwed into the positioning hole 1-2, and the axis of the threaded column 3-1 is aligned with the positioning pin 3. The axes are coincident or parallel.

[0031] Other composition and connection methods are the same as those in Embodiment 1.

specific Embodiment approach 3

[0032] Specific implementation mode three: as Figure 4 As shown, the positioning device described in this embodiment further includes an arc-shaped gasket 6 , and the arc-shaped gasket 6 is placed on the table top of the workbench 1 . The arc gasket 6 can be used to adjust the height of the steam seal arc section.

[0033] Other composition and connection methods are the same as those in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com