Quick-drying type SBR-modified emulsified asphalt sealing layer mixture and preparation method thereof

A technology of emulsified asphalt and mixture, which is applied in the field of highway engineering, can solve the problems of long molding time of emulsified asphalt road surface sealant mixture, accelerate the molding efficiency of mixture, and cracking of mixture, so as to improve the ability to resist external environmental damage , improve the overall structure, reduce the effect of cracking problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

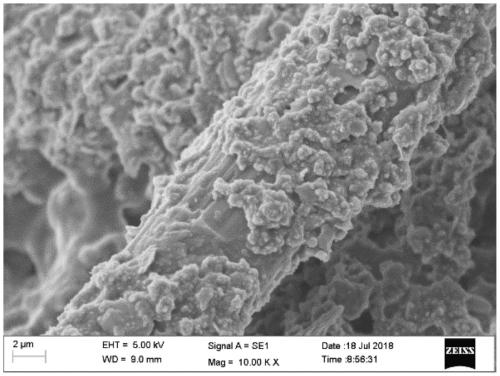

Image

Examples

Embodiment 1

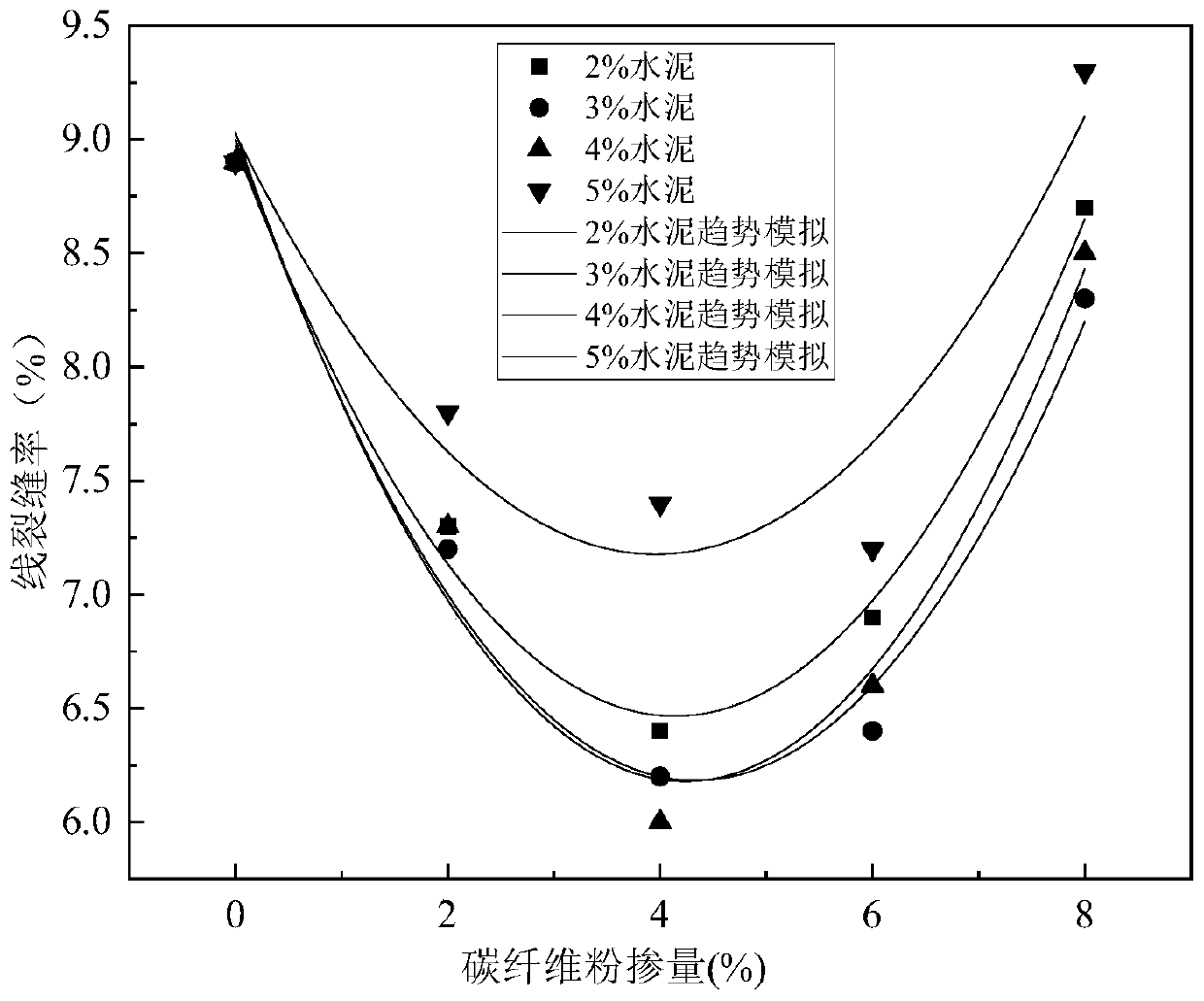

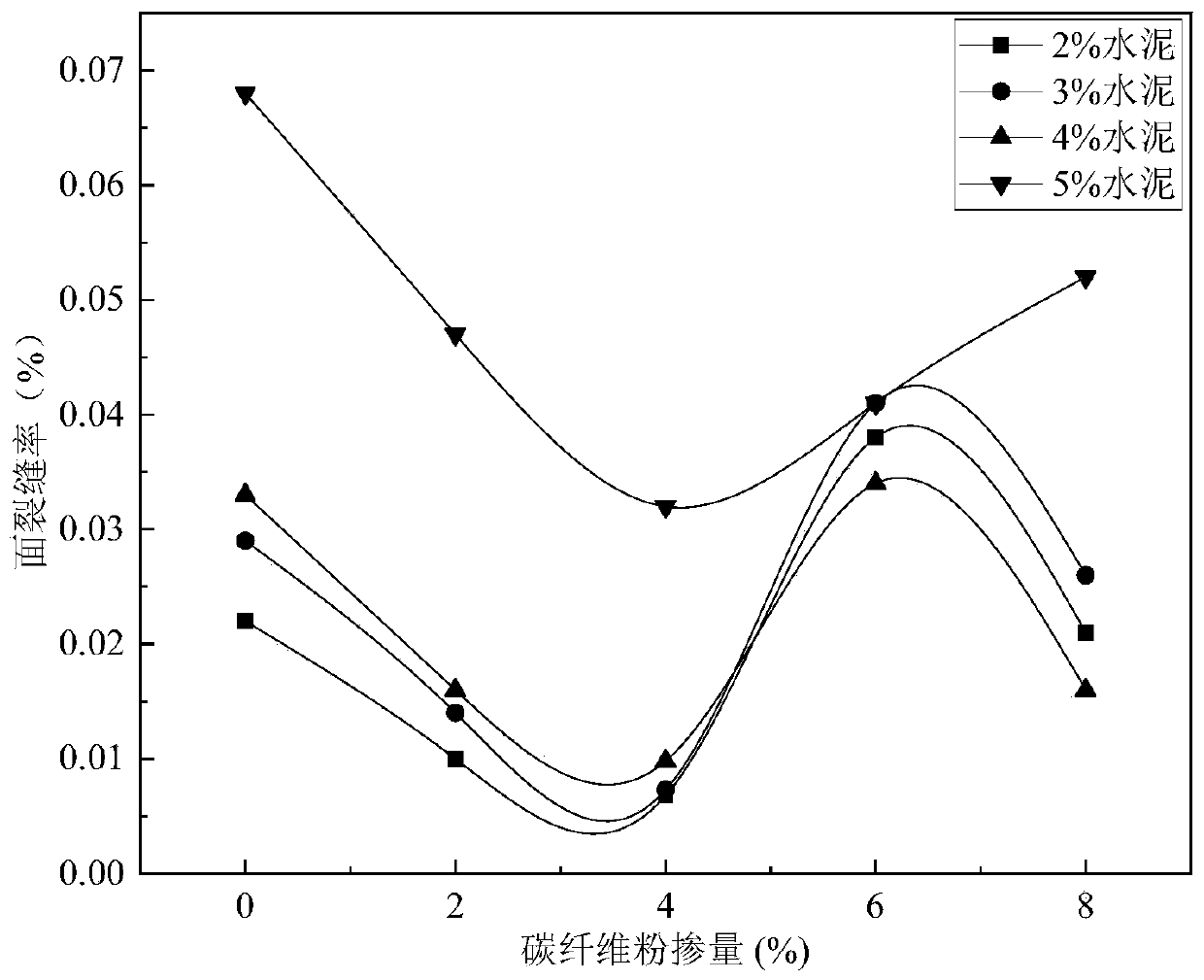

[0038] Example 1, the quick-drying SBR modified emulsified asphalt sealant mixture of the present invention is specifically composed of the following parts by mass: 100 parts of mineral material, 11 parts of SBR modified emulsified asphalt, 3 parts of cement, 5 parts of carbon fiber powder, water 12 parts, water is tap water.

Embodiment 2

[0039] Example 2, the quick-drying SBR modified emulsified asphalt sealant mixture of the present invention is specifically composed of the following parts by mass: 100 parts of mineral material, 13 parts of SBR modified emulsified asphalt, 5 parts of cement, 3 parts of carbon fiber powder, water 14 parts, water is tap water.

Embodiment 3

[0040] Example 3, the quick-drying SBR modified emulsified asphalt sealant mixture of the present invention is specifically composed of the following parts by mass: 100 parts of mineral material, 12 parts of SBR modified emulsified asphalt, 4 parts of cement, 4 parts of carbon fiber powder, water 13 parts, water is tap water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cohesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com