A kind of method for preparing 2-chloronicotinic acid with 2,3-pyridinedicarboxylic acid as raw material

A technology of dipicolinic acid and chloronicotinic acid is applied in the field of production of pesticides and pharmaceutical products, can solve the problems of unsuitability for industrial production, long process route, easy volatility and the like, and achieves easy mass production and easy availability of raw materials. , Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

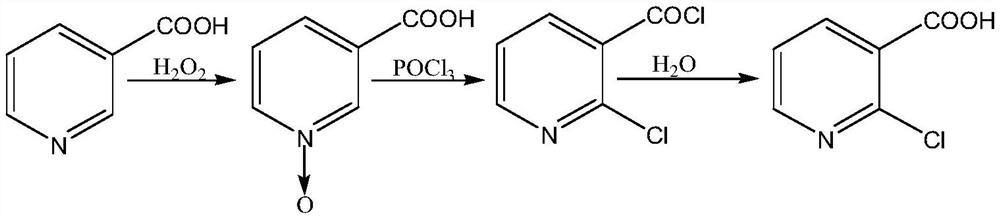

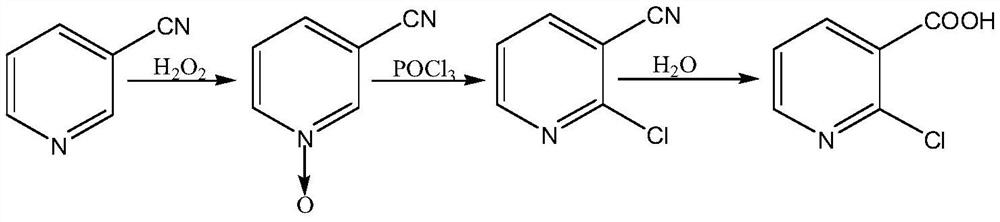

Problems solved by technology

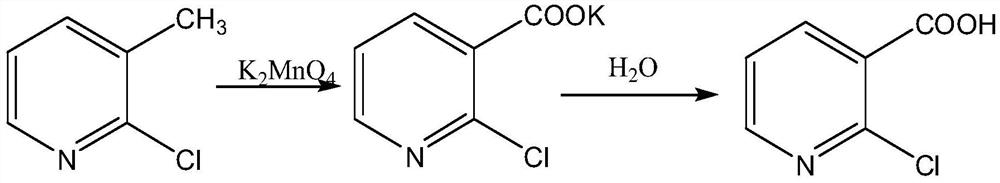

Method used

Image

Examples

Embodiment 1

[0035] 16.7g (0.1mol) of quinolinic acid was added to 150ml of water, and 31.6g of KMnO was added in batches under stirring. 4 (0.2mol), slowly warming up to 85-90°C, keep feeding chlorine gas into the system at this temperature range, monitor the reaction by TLC after 1-1.5 hours until the raw materials disappear, and the reaction is complete;

[0036] Then add 3.0g activated carbon to the reaction solution and continue to stir for 0.5 hours to decolorize, perform hot filtration at 75°C, and cool the filtrate to room temperature, add 20% NaOH aqueous solution to adjust the pH value to 5, filter , and washed the filter cake with water to obtain 14.5 g of the product 2-chloronicotinic acid with a yield of 91% and a purity of 99.1%.

[0037] After testing, the melting range of the product is: 181-182°C;

[0038] MS (m / z): 157 (M+), 140, 112, 76, 50.

Embodiment 2

[0040] Add 16.7g (0.1mol) of quinolinic acid into 300ml of NaClO aqueous solution (mass percentage is 13%), slowly heat up to 85-90°C under stirring, keep this temperature and feed chlorine into the system, 1-1.5 Hours later, TLC monitors the reaction until the raw material disappears, and the reaction is complete;

[0041] Then add 3.0g activated carbon to the reaction solution and continue to stir for 0.5 hours to decolorize, perform hot filtration at 75°C, and cool the filtrate to room temperature, add 20% NaOH aqueous solution to adjust the pH value to 5, filter , washed the filter cake with water to obtain 11.8 g of the product 2-chloronicotinic acid with a yield of 74% and a purity of 99.2%.

[0042] After testing, the melting range of the product is: 181-182°C;

[0043] MS (m / z): 157 (M+), 140, 112, 76, 50.

Embodiment 3

[0045] 16.7g (0.1mol) of quinolinic acid was added to 300ml of chloroform, and 111g of Pb(OAc) was added in batches under stirring 4 (0.25mol), keep stirring and slowly heat up to reflux, feed chlorine into the system, monitor the reaction by TLC after 3-3.5 hours until the raw materials disappear, and react completely;

[0046]Then dropwise adding 450ml of 450ml mass percentage in the reaction solution is 5% NaOH aqueous solution, separate the water layer after stirring, wash the organic layer with water and merge the water layer; the obtained water phase is heated to reflux, add 3.0g gac to continue Stir for 0.5 hours to decolorize, perform hot filtration at 75°C, and cool the filtrate to room temperature, add 20% NaOH aqueous solution to it to adjust the pH value to 5, filter, and wash the filter cake with water to obtain the product 2-chloro Niacin 13.5g, the yield is 84.7%, and the purity is 99.2%.

[0047] After testing, the melting range of the product is: 181-182°C; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com