Inorganic functional slurry with ultrahigh weather resistance, low light transmittance and high heat insulation, and preparation method thereof

A technology of light transmittance and weather resistance, which can be used in pigment paste, photovoltaic power generation, climate change adaptation, etc., and can solve problems such as low light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

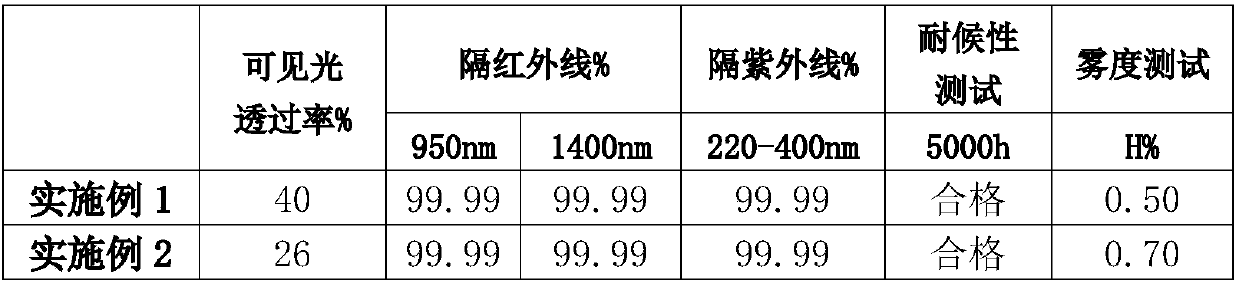

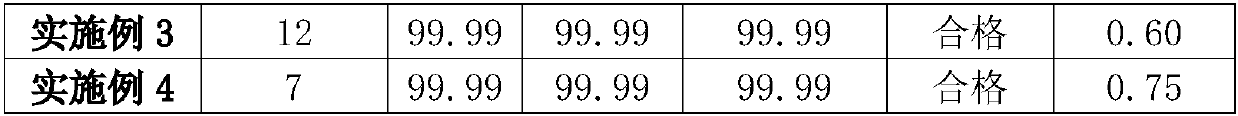

Embodiment 1

[0015] Weigh 200g of dispersant BYK 110, add it to 44.8Kg of xylene, and disperse for 15 minutes with EYJ-1500 (500rpm) high-speed disperser; then add 5Kg of S-P100 powder, increase the speed to 800rpm / min, and disperse for 4 hours. Then use the NETZSCH ZETA nano-scale circulating sand mill to perform circular grinding for 12 hours to obtain ultra-high weather resistance, low light transmittance, high heat insulation inorganic functional slurry, and the average particle size of the slurry is 40nm.

Embodiment 2

[0017] Weigh 300g dispersant BYK 161, add it to 39.7Kg ethyl acetate, and disperse it with EYJ-1500 (500rpm) high-speed disperser for 15 minutes; then add 10Kg S-P100 powder, increase the speed to 800rpm / min, and disperse for 4 hours . Then use the NETZSCH ZETA nano-scale circulating sand mill to perform circular grinding for 12 hours to obtain ultra-high weather resistance, low light transmittance, high heat insulation inorganic functional slurry, and the average particle size of the slurry is 40nm.

Embodiment 3

[0019] Weigh 400g of dispersant BYK 110, add it to 37.1Kg of xylene, disperse for 15 minutes with EYJ-1500 (500rpm) high-speed disperser; then add 12.5Kg of S-P100 powder, increase the speed to 800rpm / min, and disperse for 4 hours . Then use the NETZSCH ZETA nano-scale circulating sand mill to perform circular grinding for 12 hours to obtain ultra-high weather resistance, low light transmittance and high heat insulation inorganic functional slurry, and the average particle size of the slurry is 40nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com