A green brick tea production line and production method

A production line, green brick tea technology, applied in the field of green brick tea processing and production equipment, can solve the problems of green brick tea quality instability, high labor intensity, unhygienic, etc., to reduce the reproduction of harmful microorganisms, reduce labor costs, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

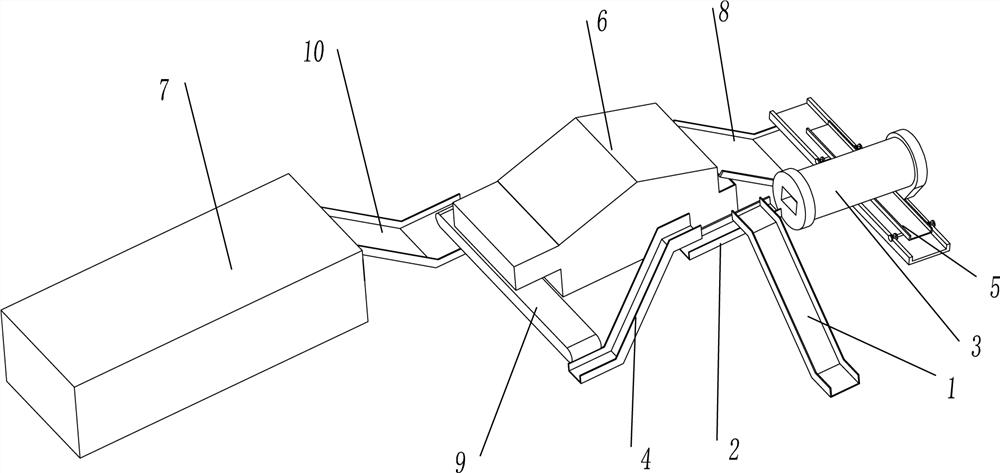

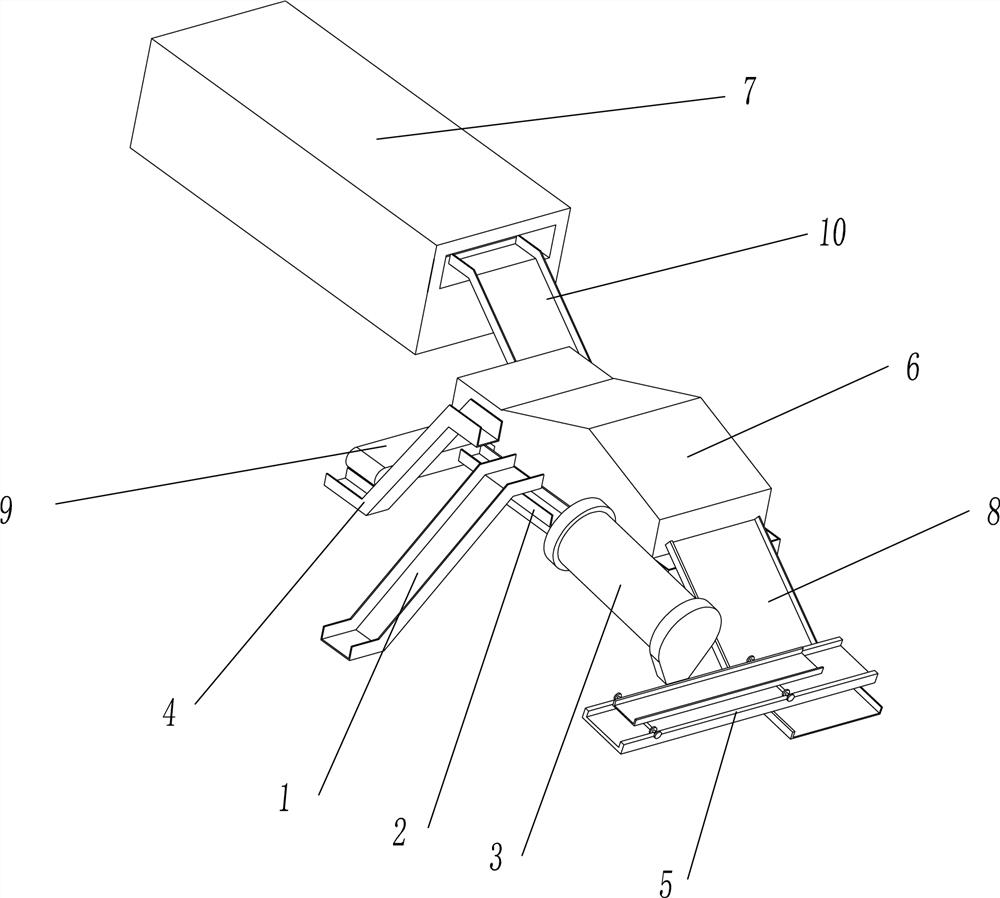

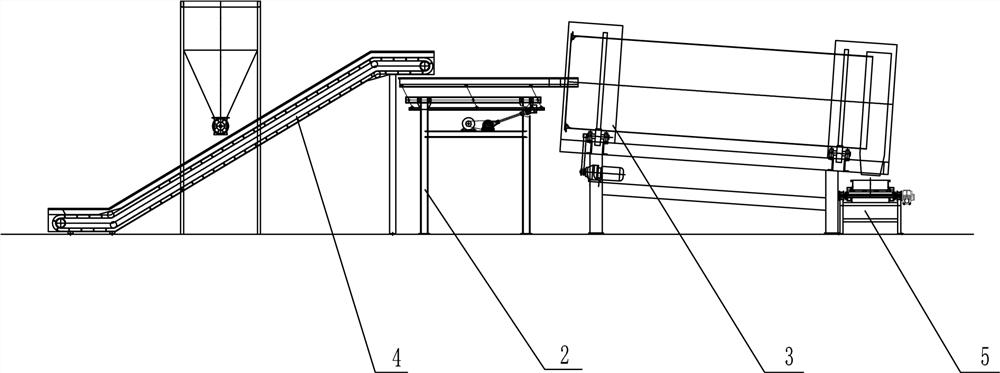

[0081] like Figure 1-6 As shown, a green brick tea production line includes a feeding device 1, a vibrating conveying device 2, a watering device 3, a yeast material adding device 4, a distributing device 5, a fermentation and deblocking device 6 and a drying device 7.

[0082] The discharge port of the feeding device 1 is arranged directly above the vibrating conveying device 2, one side of the vibrating conveying device 2 is directly opposite to the discharging port of the yeast feed adding device 4, and the other side of the vibrating conveying device 2 is directly connected to the sprinkler. The feeding port of the device 3 is facing directly; the output end of the sprinkler device 3 is located directly above one side of the distribution device 5, the other side of the distribution device 5 is located directly above the input end of the first lifting conveyor belt 8, and the upper end of the first lifting conveyor belt 8 extends into the into the fermentation and deblocki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com