Working method of fully automatic zipper production line

A working method and production line technology, applied in the direction of sliding fastener components, clothing, fasteners, etc., can solve problems such as card blocking production efficiency, and achieve the effects of convenient operation, continuous processing, and optimized process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

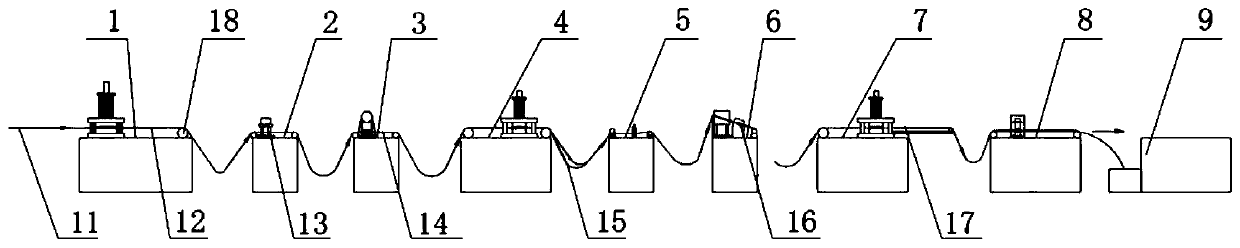

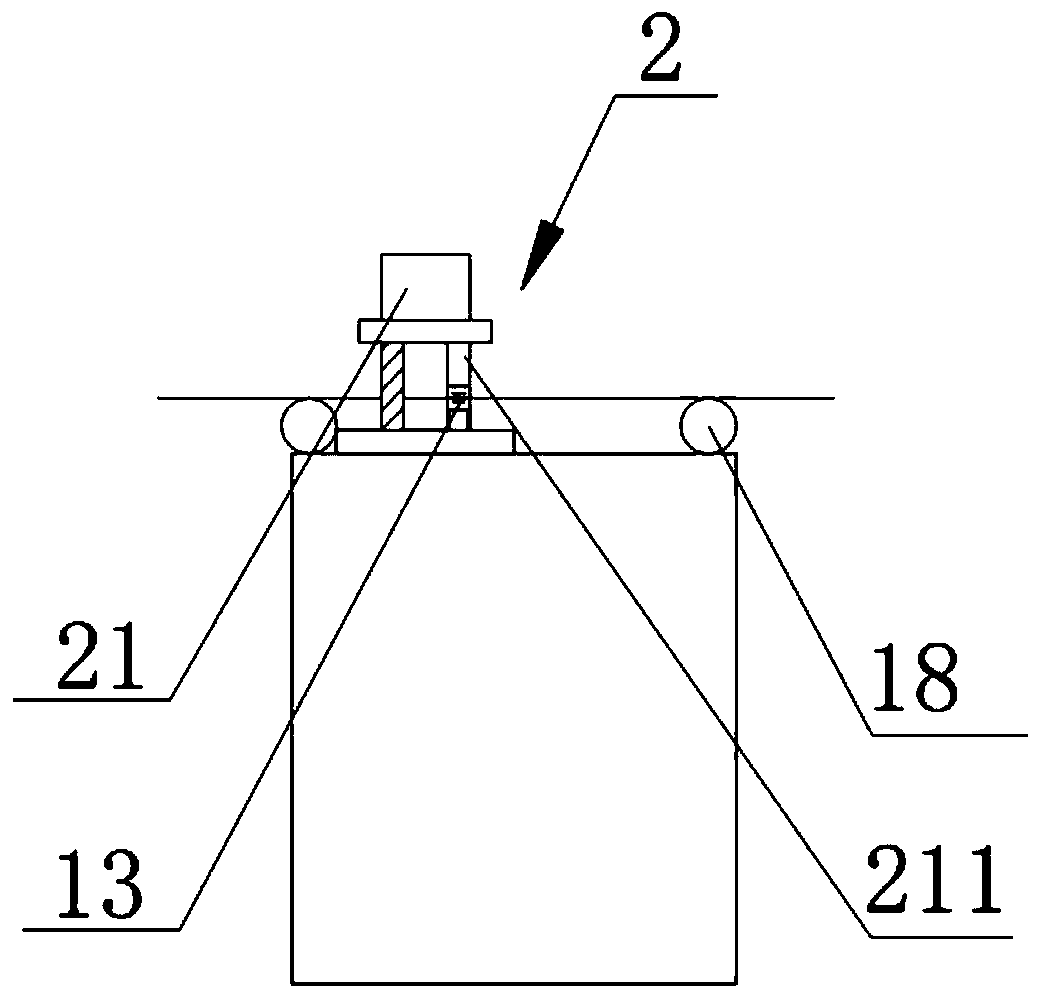

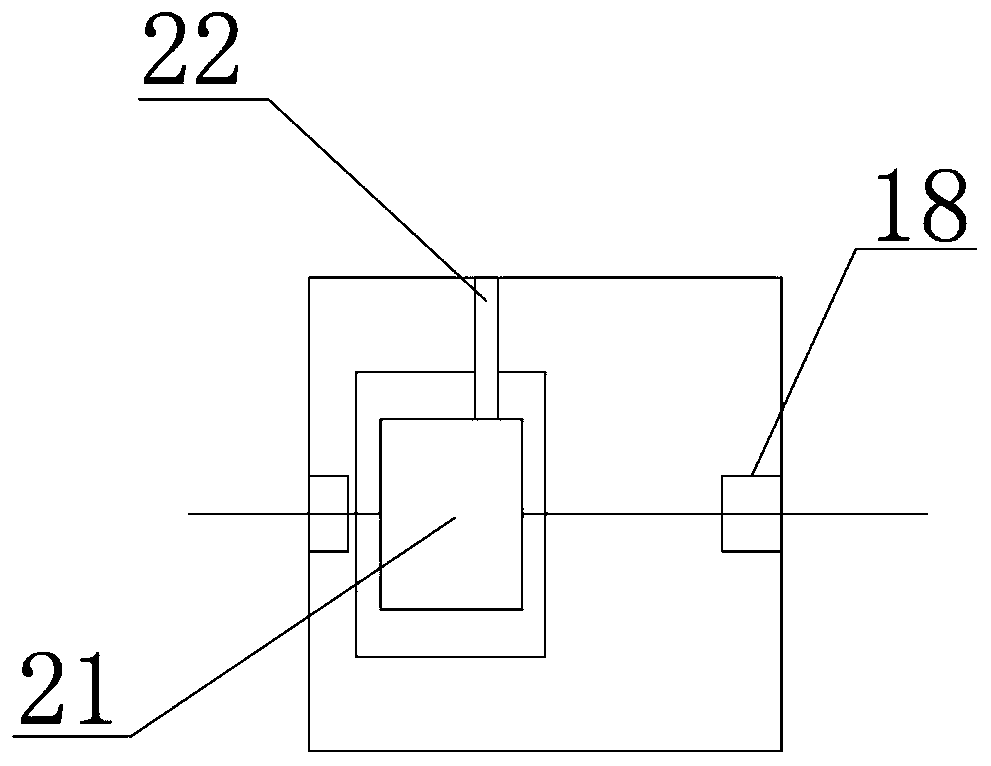

[0035] Such as Figure 1 to Figure 4 , Figure 5-Figure 9 As shown, the working method of the fully automatic zipper production line of the present embodiment, the fully automatic zipper production line includes equipment arranged in sequence according to the procedure, and the equipment includes a rice discharge machine 1, a gluing machine 2, a punching machine 3, a separate injection molding machine 4, The chain closing machine 5, the head pulling machine 6, the top stop injection molding machine 7 and the cutting machine 8, each equipment is connected in series through the conveyor belt in turn, and the input and output ends of each equipment are equipped with a belt guide device 18 connected to the conveyor belt, and the belt guide device 18 includes a roller driven by a motor, and the bottom of the transmission belt is matched with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com