Drilling device for computer production

A drilling device and computer technology, applied in the computer field, can solve problems such as low versatility, troublesome, inability to drill plates of different sizes and thicknesses, etc., and achieve the effects of easy adjustment, convenient use and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

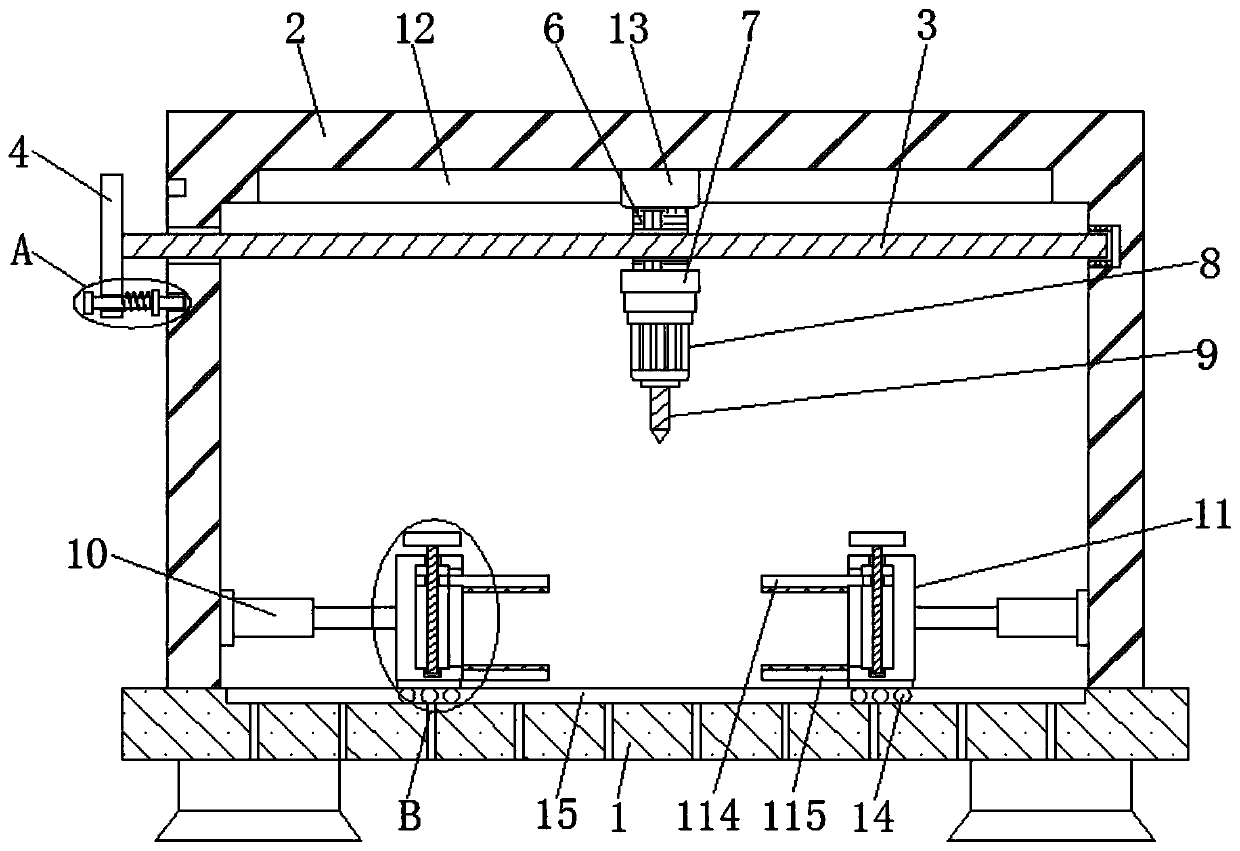

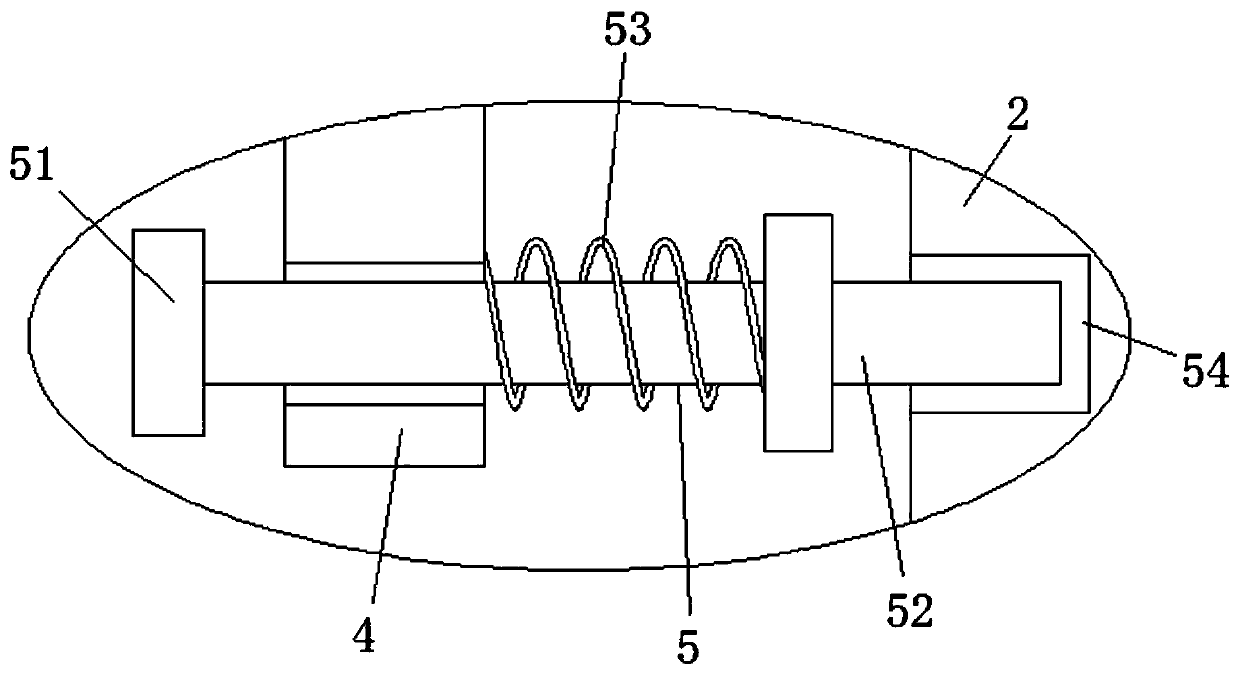

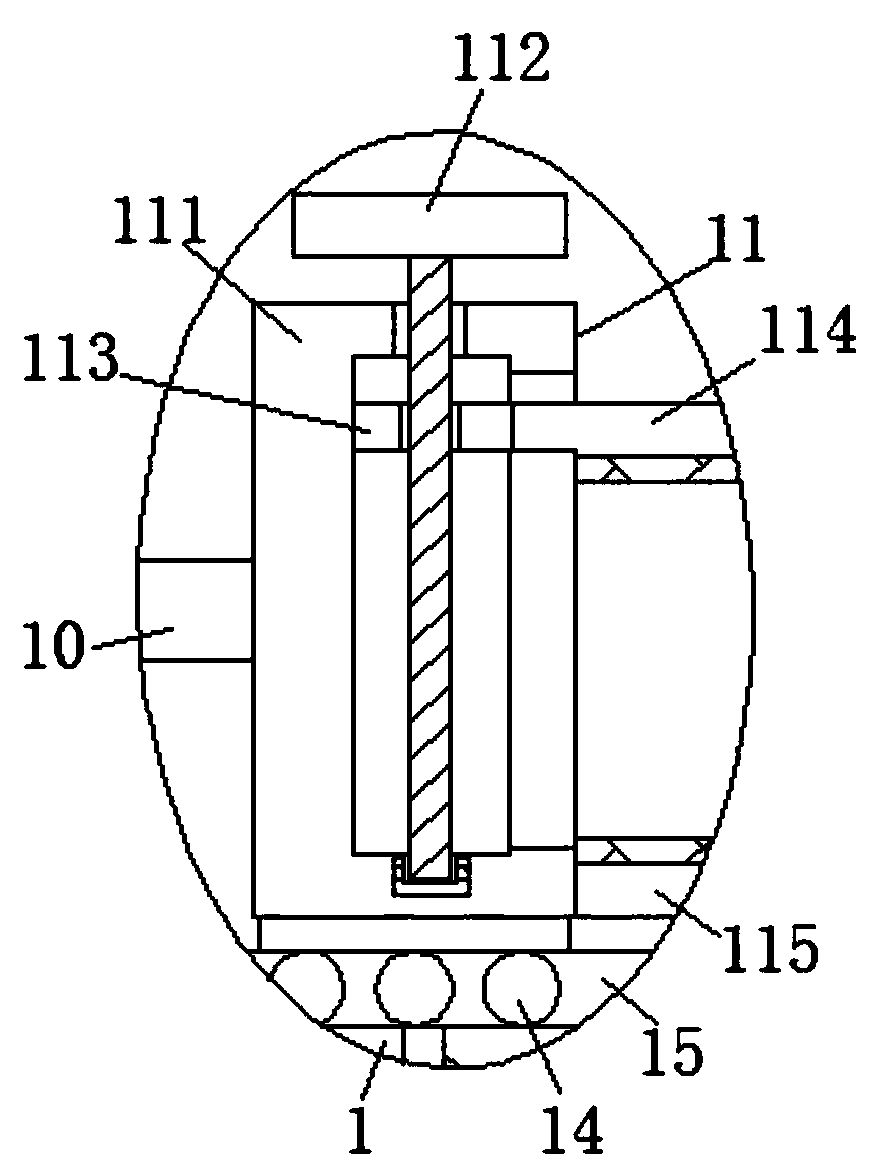

[0030] see Figure 1-3 , a drilling device for computer production, comprising a drilling platform 1, the top of the drilling platform 1 is fixedly connected with a support frame 2, the inside of the support frame 2 is provided with a threaded rod 3, the right end of the threaded rod 3 is embedded in the support The inner ring of the first bearing on the inner wall on the right side of the frame 2 is fixedly connected, the left end of the threaded rod 3 runs through and extends to the left side of the support frame 2, the left end of the threaded rod 3 is fixedly connected with the turntable 4, and the turntable 4 is provided with a limiting device 5. The threaded rod 3 and the internal thread of the support frame 2 are connected with a threaded circle 6, the bottom of the threaded circle 6 is fixedly connected with a hydraulic telescopic rod 7, and the bottom of the pressure telescopic rod 7 is fixedly connected with a drive motor 8, and the drive motor 8 The model is YY5612,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com