Robot gripper impact-resistant structure

A robot gripper and impact-resistant technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of robots being susceptible to impact collisions, affecting robot life and grasping efficiency, and heavy waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

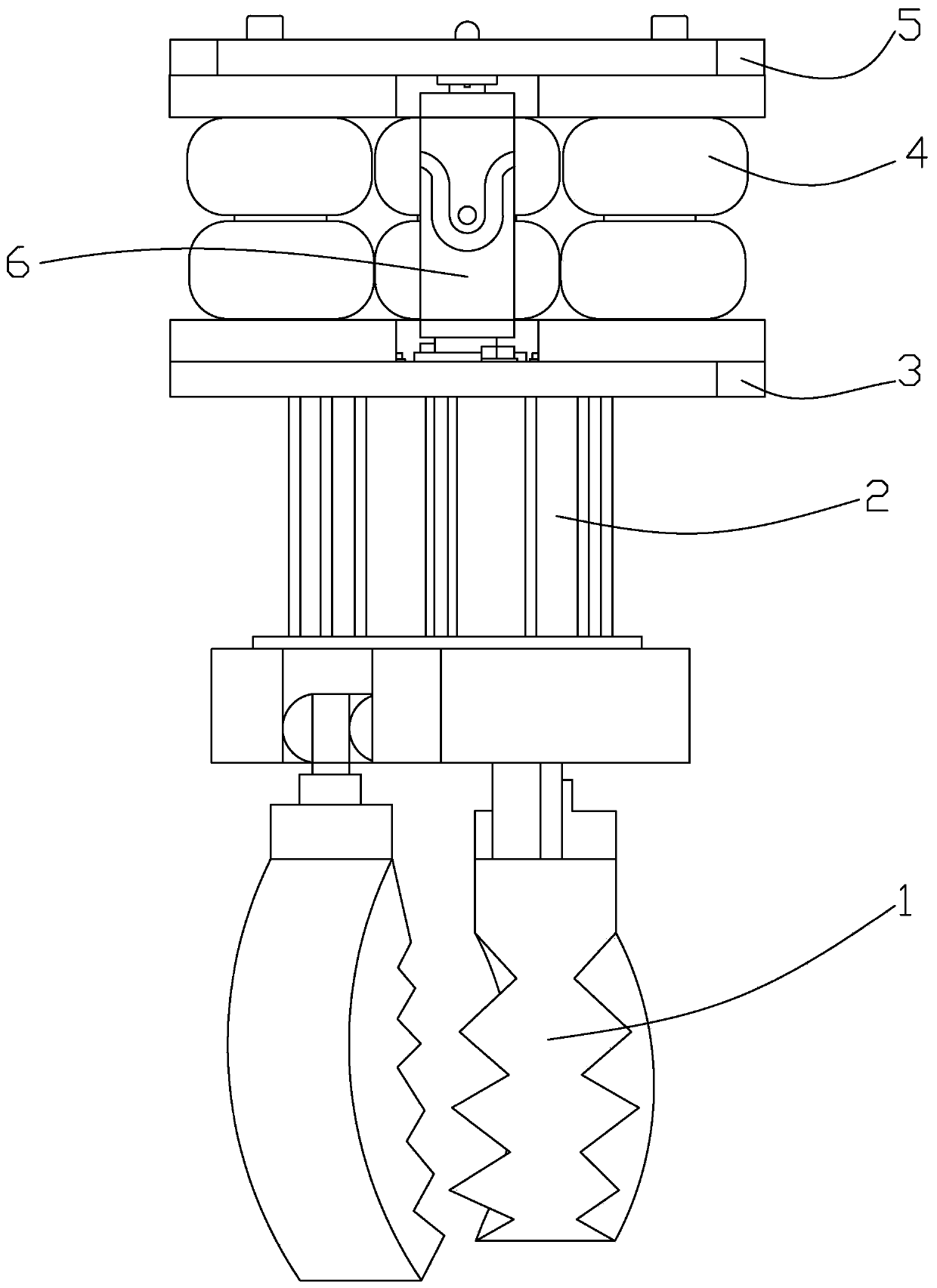

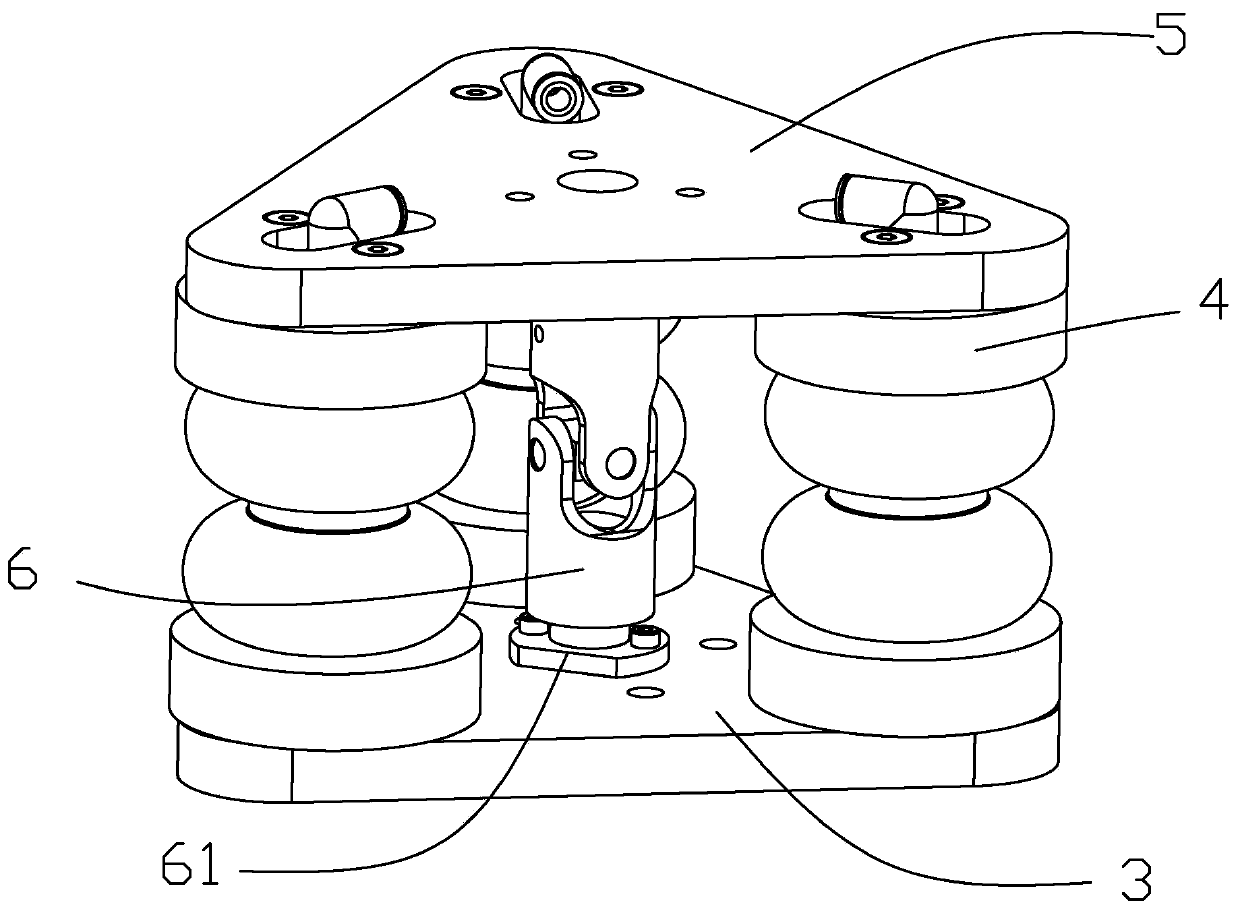

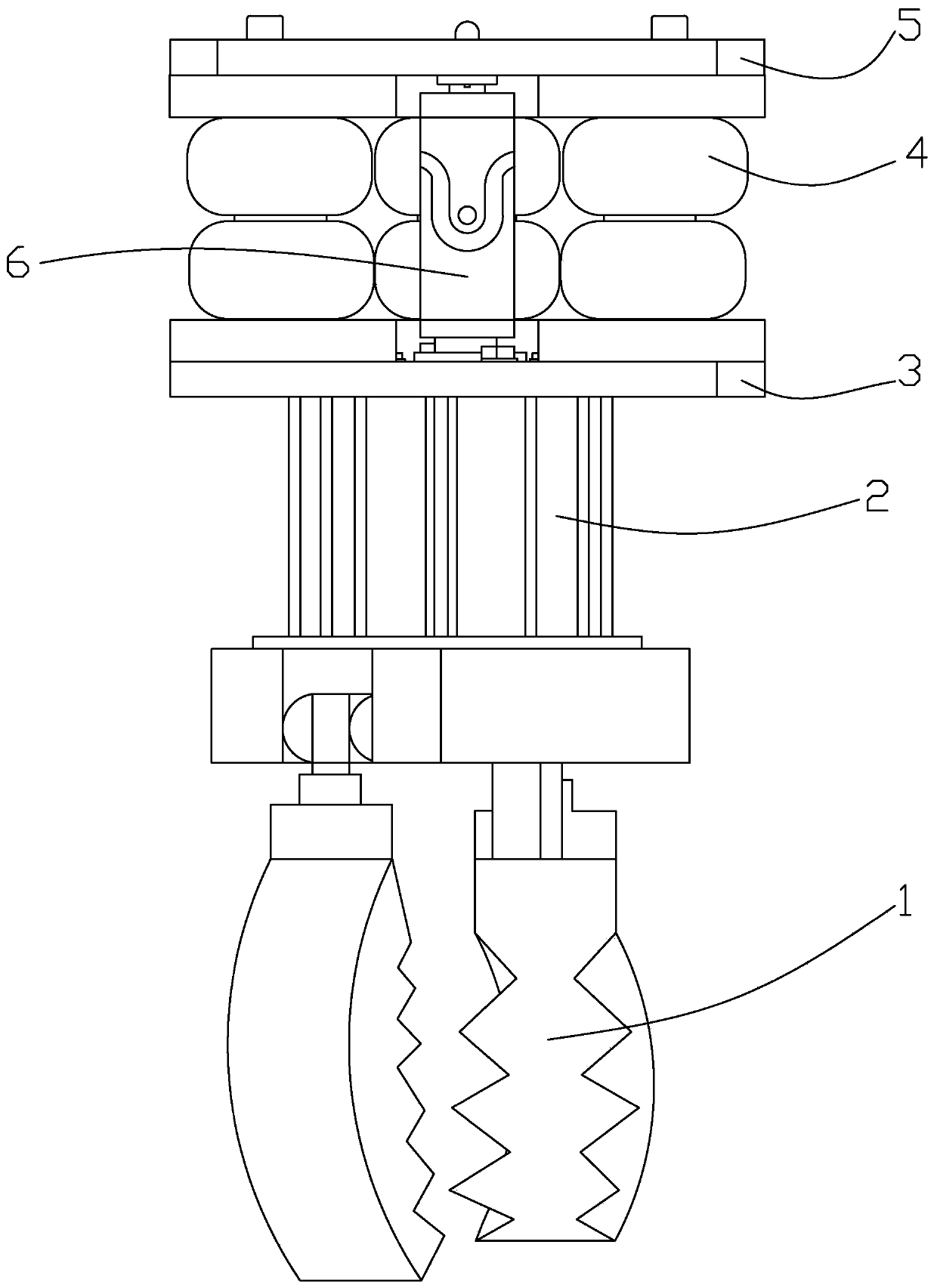

[0015] refer to figure 1 , figure 2 . An anti-shock structure for a robot gripper, comprising an upper hanging plate 5 and a lower hanging plate 3, and an air spring 4 and a universal coupling 6 are installed and connected between the upper and lower hanging plates. The upper surface of the upper hanging plate 5 is installed and fixed on the robot arm, and three air springs 4 are fixed between the upper and lower hanging plates 5 and 3, and are fixed on the two plates by the universal coupling 6 through the upper and lower coupling shafts 61. At the center position of the lower hanging plate 3, the pneumatic component 2 is installed on the lower surface of the lower hanging plate 3, and the pneumatic component 2 controls the gripper 1 of the clamp.

[0016] refer to figure 2 . The hanging boards 5 and 3 are triangular in shape, which is only an embodiment, and does not limit the present invention to be applicable to other shapes, such as square, circular, etc. Before th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com