Hot runner system for processing and manufacturing main runner and branch runner from one block of material

A technology of material processing and hot runner, which is applied in the field of hot runner, can solve the problems of unstable heating performance, affecting work efficiency, and prone to glue leakage, etc., to achieve fast, uniform and stable heating performance, reduce maintenance links, and reduce glue leakage links Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

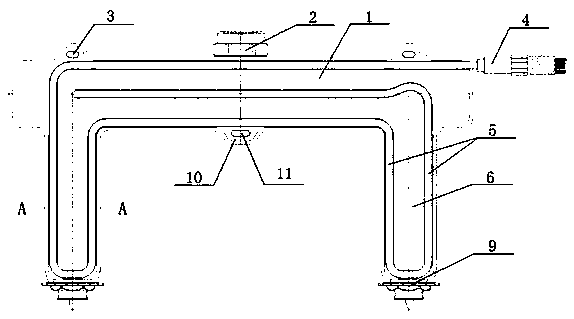

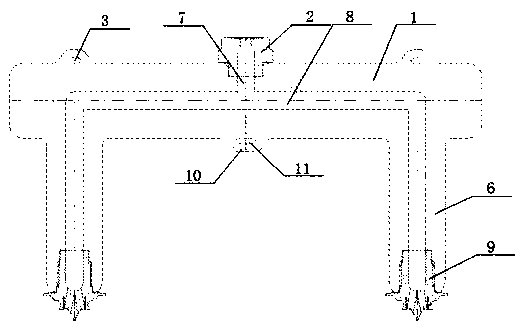

[0023] The hot runner system that completes the main channel and the sub-runner by processing and manufacturing from one piece of material, the technical solution it adopts is: it includes the hot runner panel 1, the main nozzle 2, the bolt hole 3, the terminal head 4, the heating tube 5, and the distribution column 6 , main channel 7, branch channel 8, hot nozzle 9, center nail 10, the upper center of the hot runner panel 1 is provided with a main nozzle 2, the main nozzle 2 is a "T" shaped main nozzle, the main nozzle 2 The lower end of the main nozzle 2 is connected to the hot runner panel 1, the upper end of the main nozzle 2 is stuck on the upper surface of the hot runner panel 1, a bolt hole 3 is provided on both sides of the upper end of the hot runner panel 1, and the bottom of the hot runner panel 1 is provided with Two splitter columns 6 with the same structure, the hot runner panel 1 is integrally connected with the two splitter columns 6, and the bottom of each spli...

Embodiment 2

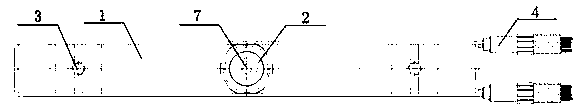

[0025] The hot runner system that completes the main channel and the sub-runner by processing and manufacturing from one piece of material, the technical solution it adopts is: it includes the hot runner panel 1, the main nozzle 2, the bolt hole 3, the terminal head 4, the heating tube 5, and the distribution column 6 , the main channel 7, the branch channel 8, the hot nozzle 9, the hot runner panel 1 is a long hot runner panel, the upper center of the hot runner panel 1 is provided with the main nozzle 2, and the upper end of the hot runner panel 1 is provided on both sides. There is a bolt hole 3, the bottom of the hot runner panel 1 is provided with a splitter column 6, and the splitter column 6 is set at the right end of the hot runner panel 1, the hot runner panel 1 and the splitter column 6 are integrally connected, and the bottom of the splitter column 6 There is a hot nozzle 9, the right end of the hot runner panel 1 is provided with a terminal 4, the terminal 4 is conn...

Embodiment 3

[0027] The hot runner system that completes the main channel and the sub-runner by processing and manufacturing from one piece of material, the technical solution it adopts is: it includes the hot runner panel 1, the main nozzle 2, the bolt hole 3, the terminal head 4, the heating tube 5, and the distribution column 6 , main channel 7, runner 8, hot nozzle 9, center nail 10, hot runner panel 1 is a hot runner panel with three long panels arranged in an equilateral triangle, and the center of the upper end of hot runner panel 1 is provided with a main nozzle 2. There is a center nail 10 corresponding to the bottom of the main nozzle, and the center nail 10 is set at the bottom of the hot runner panel 1. There is a bolt hole 3 at the upper end of each strip panel, and the bottom of each strip panel corresponds to There is a splitter column 6, and the hot runner panel 1 is integrally connected with the three splitter columns 6. The bottom of each splitter column 6 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com