Lithium porcelain stone tailings defluorination device based on solvent flotation method

A flotation method, lithium china stone technology, applied in flotation, solid separation and other directions, can solve problems such as affecting the processing progress of glass-ceramic plates, unable to ensure sufficient reaction of additives, waste of resource reaction time, etc., to ensure sufficient consumption, The effect of accelerating defluorination and promoting sufficient reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

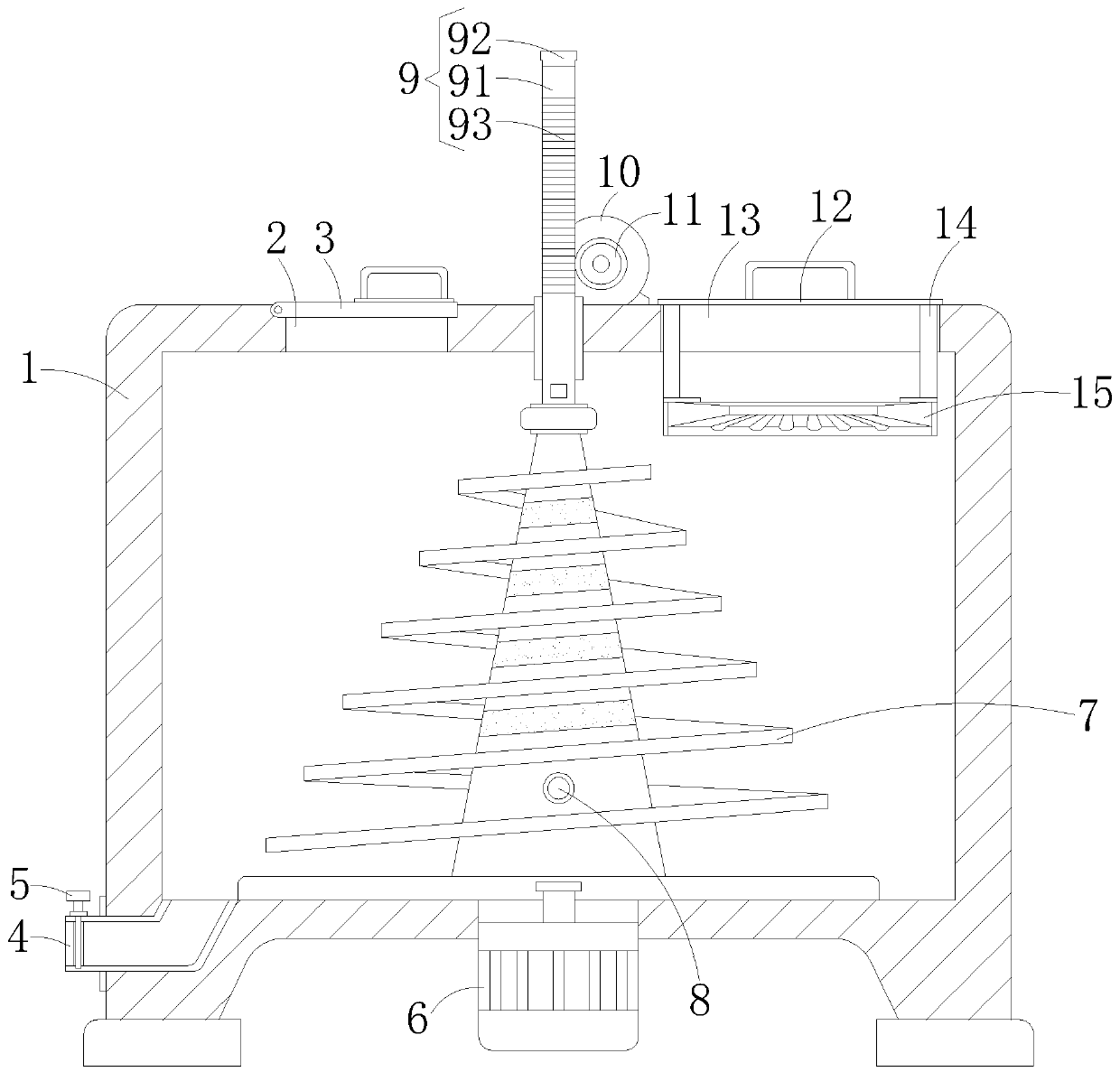

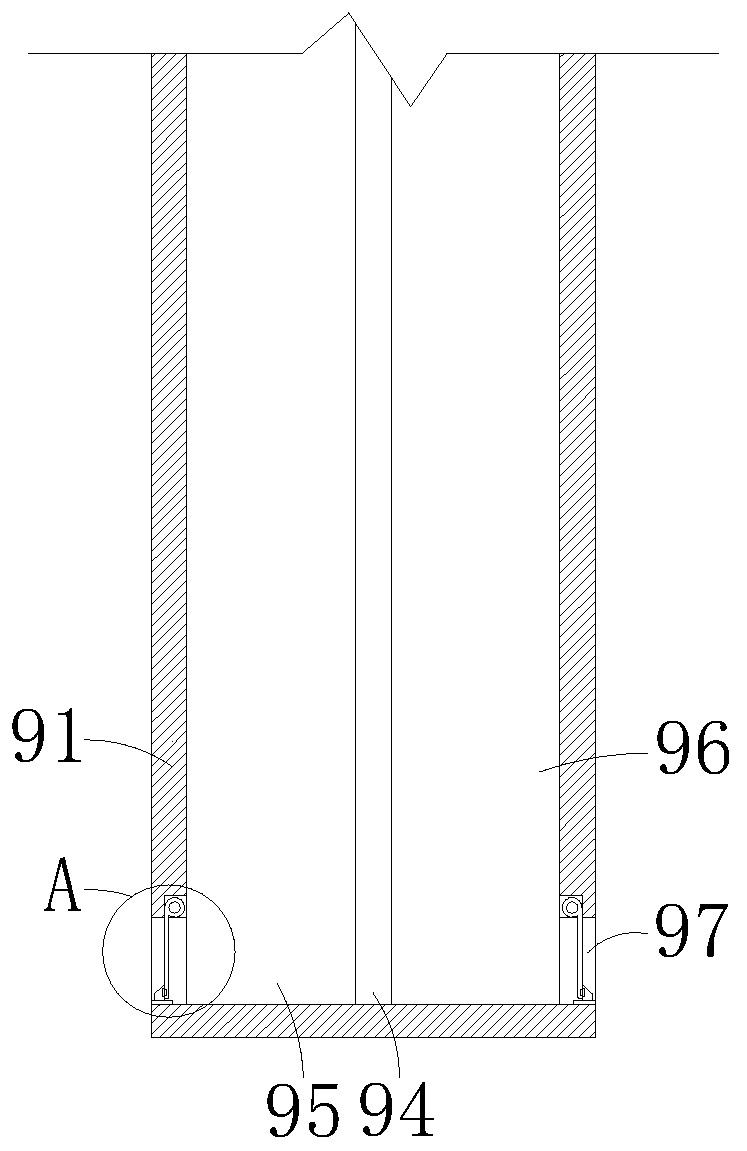

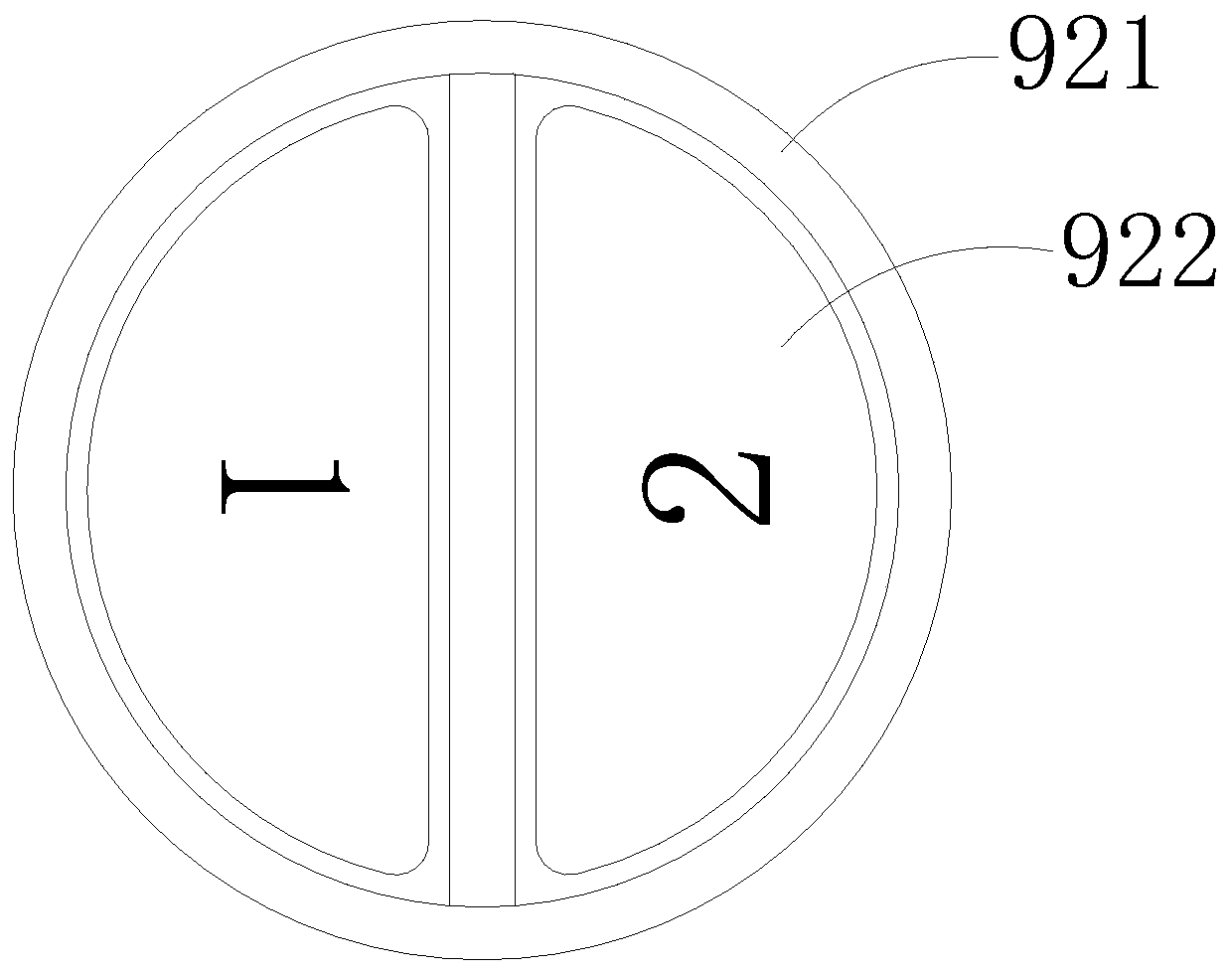

[0029]see Figure 1-7 , the present invention provides a technical solution: a lithium china stone tailings defluorination equipment based on solvent flotation, including a body 1, a drive motor 6, an acceleration mechanism 7, a one-way valve 8, a feeding mechanism 9, and a rotating motor 10 , gear 11, cover plate 12, port 13, connecting rod 14 and collection mechanism 15, driving motor 6 is fixedly installed in the middle part of body 1 bottom, and the output shaft of driving motor 6 runs through the middle part of body 1 inner bottom and is connected with the acceleration mechanism The middle part of the bottom of 7 is fixedly connected, the bottom of the acceleration mechanism 7 is slidingly connected to the inner bottom of the body 1, the one-way valve 8 is fixedly installed on the bottom of the front of the acceleration mechanism 7, and the upper and lower ends of the feeding mechanism 9 respectively run through the top middle of the body 1 and the bottom of the feeding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com