Pyroelectric ceramic material and preparation method thereof

A technology of pyroelectric ceramics and raw materials, which is applied in the field of functional ceramic materials, can solve the problems of increased phase transition temperature range, increased product cost, and false reporting, and achieves the effect of high pyroelectric coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

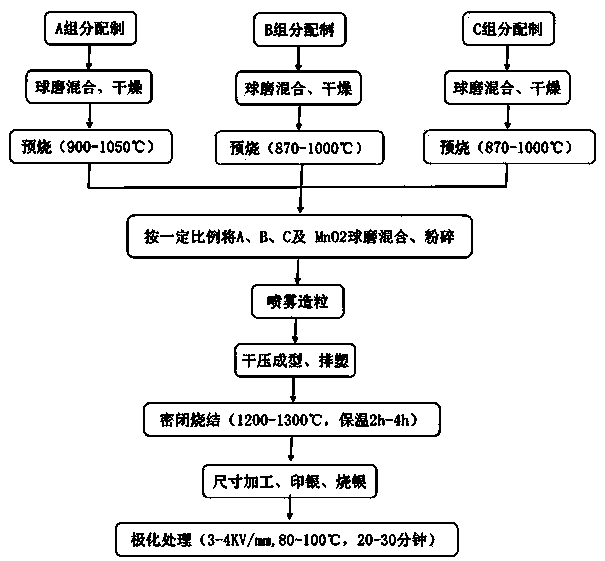

Method used

Image

Examples

Embodiment 1

[0032] respectively according to

[0033]

[0034] will analyze pure Pb 3 o 4 , ZrO 2 、TiO 2 , Nb 2 o 5 , Fe 2 o 3 , ZnO, La 2 o 3 , SrCO 3 The raw materials are prepared according to the stoichiometric ratio of three kinds of powders A, B, and C, wherein x=0.008, y=0.03, z=0.02; the prepared three kinds of powders are mixed evenly according to the wet ball milling method, specifically, the wet The ball milling process is: material: grinding medium: deionized water = 1:2:0.8, the grinding medium is zirconium balls of Φ6mm~Φ16mm, and the ball milling time is 12 hours; Carry out airtight pre-firing in an aluminum crucible according to the synthesis process in Table 2.

[0035] Component

Pre-burning temperature (°C)

Holding time (h)

A

980

4

B

950

4

C

930

4

[0036] Preliminary crushing of pre-burned A, B, and C materials and analysis of pure MnO 2The raw materials were weighed and prepared according to the ...

Embodiment 2

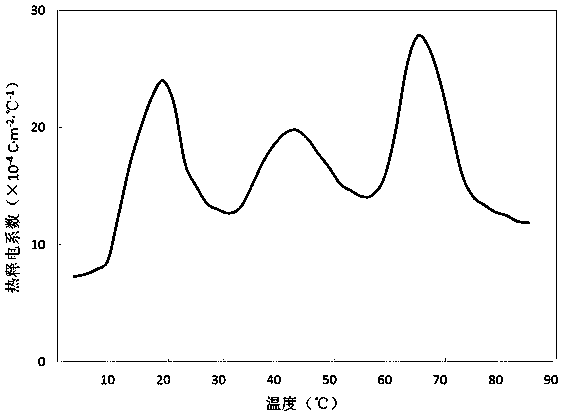

[0046] The difference between Example 2 and Example 1 is that the three-component calcining process of A, B, and C is different. The specific calcining process is shown in Table 6, and the A and B components used in Examples 2-1~2-3 , C three component mass ratio and MnO 2 The addition amount corresponds to Example 1-1~1-3 (Table 3), and other preparation steps are exactly the same as Example 1, and the performance parameters of the obtained pyroelectric ceramic material are shown in Table 4 and Table 5.

[0047] Component

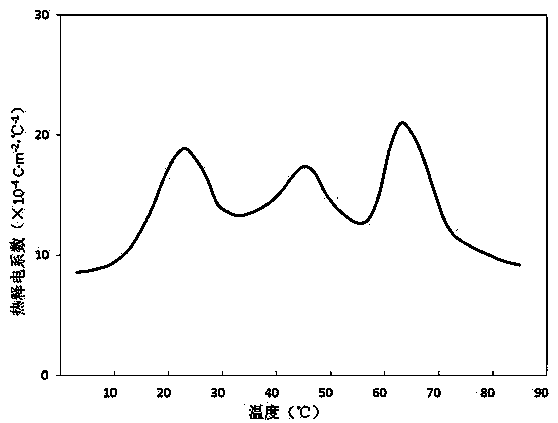

[0048] Industrial Applicability: It can be seen from the above introduction that the pyroelectric ceramic material prepared by the present invention has a higher pyroelectric coefficient at room temperature, a lower dielectric loss, and a moderate dielectric constant. Compared with the prior art In the temperature range of 10°C~80°C, the pyroelectric coefficient and detection value are relatively high, and the thickness of the ceramic sheet is ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com