Sealing material for repairing sealing defects of oil-immersed equipment and its preparation device

A plugging material and a technology for preparing a device are applied in the field of leakage plugging, which can solve the problems of unsatisfactory bonding effect, affecting the shape and structure of electrical equipment, and falling off of plugging materials, achieving high strength and anti-corrosion properties, and improving plugging. Efficiency and plugging performance, strength and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

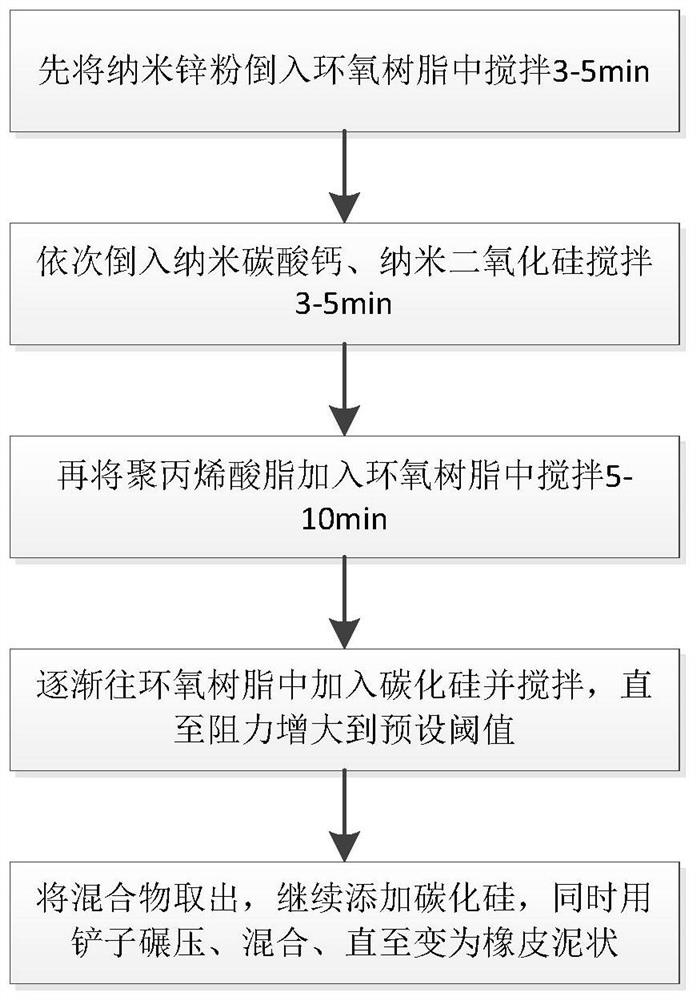

[0036] This embodiment discloses a plugging material for repairing sealing defects of oil-immersed equipment, including two components of 70% base material and 30% auxiliary material, wherein:

[0037] The base material is 15% according to the proportion of epoxy resin E44, 15% of polyacrylate, 8% of nano-silicon dioxide, 36% of nano-silicon carbide, 20% of nano-calcium carbonate, and 20% of nano-zinc powder. It is made by mixing and stirring with a specific gravity of 6%;

[0038] The auxiliary materials are mixed according to the proportion of FS-2B curing agent of 21%, the proportion of nano-silicon dioxide is 7%, the proportion of nano-silicon carbide is 44%, the proportion of nano-calcium carbonate is 19%, and the proportion of nano-zinc powder is 9%. made;

[0039] Before mixing and stirring, the nano-silica, nano-silicon carbide, nano-calcium carbonate and nano-zinc powder are dried, dehydrated, and degassed. For 2 ~ 3h.

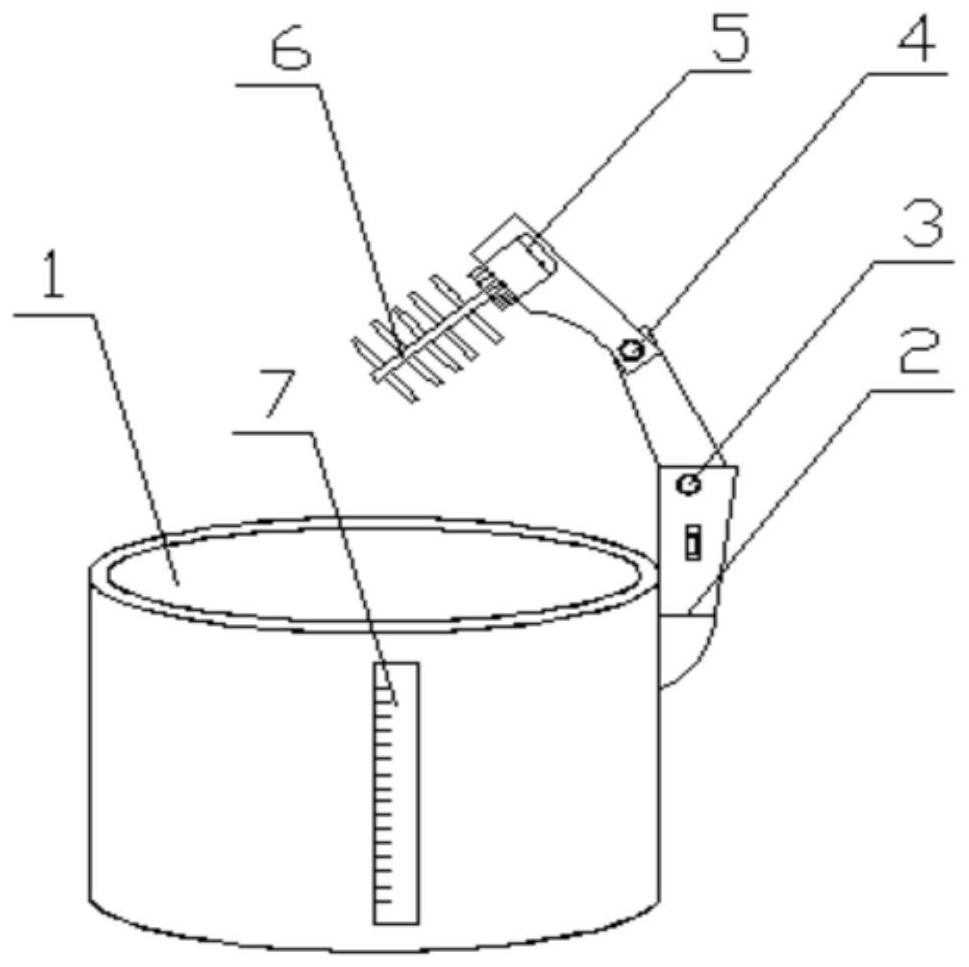

[0040] like figure 1 As shown, the preparat...

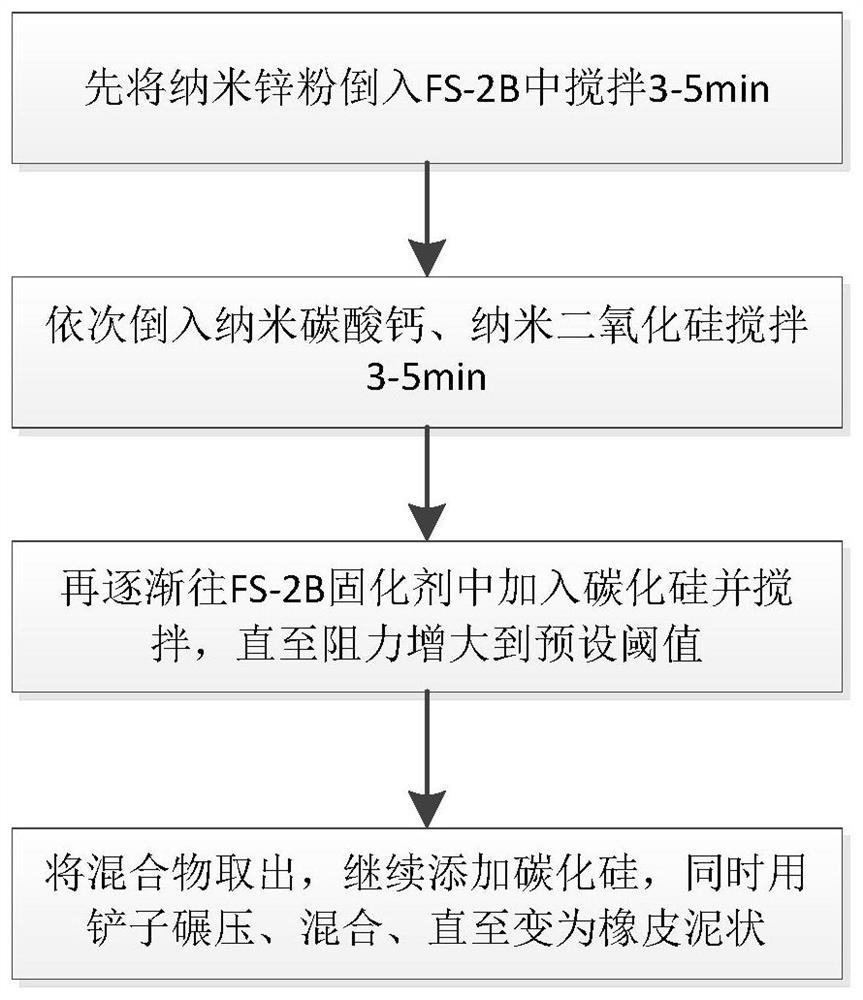

Embodiment 2

[0053] The difference between embodiment 2 and embodiment 1 is that no polyacrylic resin is added, and the base material is 30% by epoxy resin E44 proportion, and the proportion of nano silicon dioxide is 8%, the proportion of nano silicon carbide is 36%, and the proportion of nano calcium carbonate The specific gravity is 20%, and the specific gravity of nano-zinc powder is 6% by mixing and stirring;

[0054] The auxiliary materials are still mixed according to the proportion of FS-2B curing agent of 21%, the proportion of nano-silicon dioxide is 7%, the proportion of nano-silicon carbide is 44%, the proportion of nano-calcium carbonate is 19%, and the proportion of nano-zinc powder is 9%. to make;

[0055] Before mixing and stirring, the nano-silica, nano-silicon carbide, nano-calcium carbonate and nano-zinc powder are dried, dehydrated, and degassed. For 2 ~ 3h.

[0056] The preparation process of the substrate is as follows:

[0057] (a) Pour the nano-zinc powder into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com