Matte brick grinding crack-removing polishing liquid and preparation method thereof

A polishing liquid and matt brick technology, applied in the field of polishing liquid, can solve problems such as hindering development and grinding head marks, and achieve the effects of reducing flocculation, increasing transparency and reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

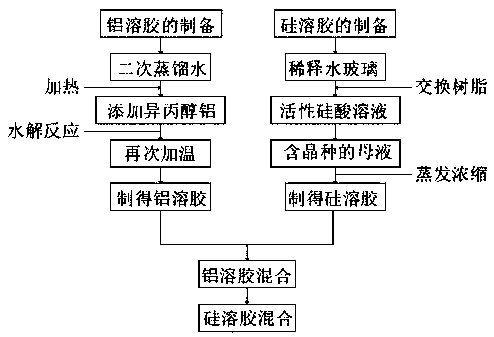

[0034] see figure 1 , a polishing solution for removing grinding marks of matt tiles, its composition includes: polishing solution A component, polishing solution B component, polishing solution C component and polishing solution D component, the polishing solution A component is silica sol, Component B of polishing liquid is aluminum sol, component C of polishing liquid is dispersant and catalyst, component D of polishing liquid is deionized water, component A of polishing liquid, component B of polishing liquid, component C of polishing liquid and polishing liquid Component D, according to the mass ratio, is 10 parts of silica sol, 30 parts of aluminum sol, 0.1 part of dispersant and 80 parts of deionized water. It can realize the mixing of two kinds of inorganic materials, which can not only repair matt bricks but also polish them with water. The wear marks produced in the process will not change the luminosity of the original tiles, so as to achieve the double effect of re...

Embodiment 2

[0045] A polishing solution for removing grinding marks on matt tiles, the composition of which includes: component A of the polishing solution, component B of the polishing solution, component C of the polishing solution, and component D of the polishing solution. The component A of the polishing solution is silica sol. Liquid B component is aluminum sol, polishing liquid C component is dispersant and catalyst, polishing liquid D component is deionized water, polishing liquid A component, polishing liquid B component, polishing liquid C component and polishing liquid D The components, according to the mass ratio, are 30 parts of silica sol, 10 parts of aluminum sol, 0.5 parts of dispersant and 80 parts of deionized water, which can realize the mixing of two kinds of inorganic materials, which can not only repair matt bricks in the process of water grinding and polishing of bricks The wear marks produced in the process will not change the luminosity of the original tiles, so as...

Embodiment 3

[0056] A polishing solution for removing grinding marks on matt tiles, the composition of which includes: component A of the polishing solution, component B of the polishing solution, component C of the polishing solution, and component D of the polishing solution. The component A of the polishing solution is silica sol. Liquid B component is aluminum sol, polishing liquid C component is dispersant and catalyst, polishing liquid D component is deionized water, polishing liquid A component, polishing liquid B component, polishing liquid C component and polishing liquid D Components, according to the mass ratio, are 20 parts of silica sol, 20 parts of aluminum sol, 0.3 parts of dispersant and 60 parts of deionized water, which can realize the mixing of two kinds of inorganic materials, which can not only repair matt bricks in the process of brick water grinding and polishing The wear marks produced in the process will not change the luminosity of the original tiles, so as to achi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com