Device and method for transporting raw material powdered coal used for gasifier high-pressure bin and replacing plunger

A high-pressure bin and gasifier technology, which is applied to the field of the raw material pulverized coal conveying plunger replacement device in the high-pressure bin of the gasifier, can solve the problems of large equipment investment and high operating costs, and achieves low space occupation rate and good sealing effect. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

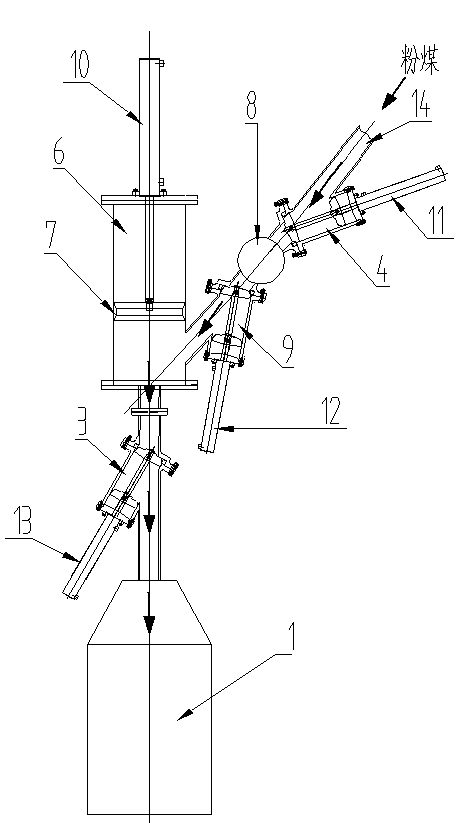

[0049] Embodiment 1: The present invention includes a plunger replacement device for raw pulverized coal delivery and a replacement method.

[0050] The replacement device includes: a plunger cylinder 6, a plunger 7, a plunger driving device 10, a pulverized coal delivery pipeline 14, a plunger cylinder feed valve, a feed pulverized coal sealing valve and a power station;

[0051] The plunger 7 is positioned in the plunger cylinder 6, and one end of the plunger cylinder 6 is connected with a plunger driving device 10, and the driving rod of the plunger driving device 10 is connected with the plunger 7 in the plunger cylinder 6, and the plunger driving device 10 Drive the plunger 7 to realize the driving action;

[0052] The other end of the plunger cylinder 6 is connected with a feed pulverized coal sealing valve, and the feed pulverized coal sealing valve is connected to the raw pulverized coal feed port of the high pressure chamber of the gasifier;

[0053] A plunger cylind...

Embodiment 2

[0071] Embodiment 2: The present invention includes a plunger replacement device for raw pulverized coal delivery and a replacement method.

[0072] The replacement device includes: high-pressure bin feeding lock hopper valve 2, lock hopper valve 5, plunger cylinder 6, plunger 7, plunger driving device 10, pulverized coal delivery pipeline 14, plunger cylinder feed valve, inlet Feed pulverized coal sealing valve and power station;

[0073] The plunger 7 is positioned in the plunger cylinder 6, and one end of the plunger cylinder 6 is connected with a plunger driving device 10, and the driving rod of the plunger driving device 10 is connected with the plunger 7 in the plunger cylinder 6, and the plunger driving device 10 Drive the plunger 7 to realize the driving action;

[0074] The other end of the plunger cylinder 6 is connected with a pulverized coal feed sealing valve, and the pulverized coal feed sealing valve is connected to the raw pulverized coal feed port of the high...

Embodiment 3

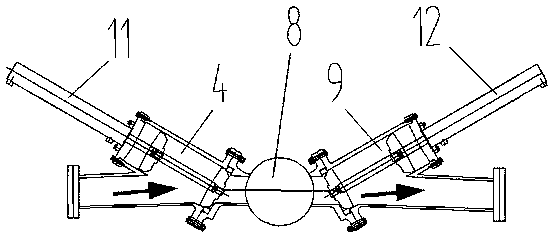

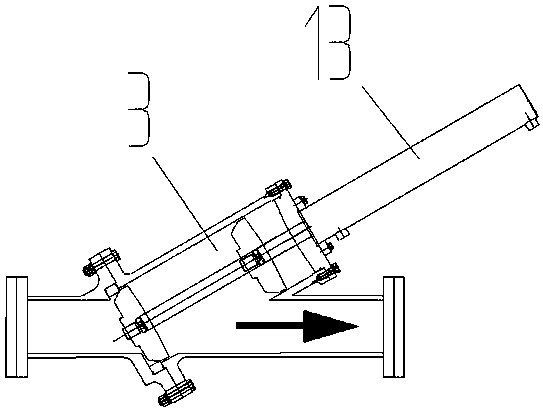

[0093] Embodiment 3: The plunger cylinder feed valve includes: a primary pulverized coal sealing valve 9, a primary driving device 12 and a buffer chamber 8; there are connecting pipes at both ends of the buffer chamber 8, and on the connecting pipe at one end A primary pulverized coal sealing valve 9 is connected; the primary pulverized coal sealing valve 9 is installed on the connecting pipeline; a primary driving device 12 is connected to the primary pulverized coal sealing valve 9 .

[0094] Others are the same as implementation 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com