Automatic adjusting device for built-in volume ratio of fuel cell air compressor

An air compressor and fuel cell technology, applied in the field of air compressors, can solve problems affecting the efficiency of fuel cell systems, waste of power consumption, and reduce compressor efficiency, so as to achieve high applicability, reduce energy consumption, and improve compressor efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

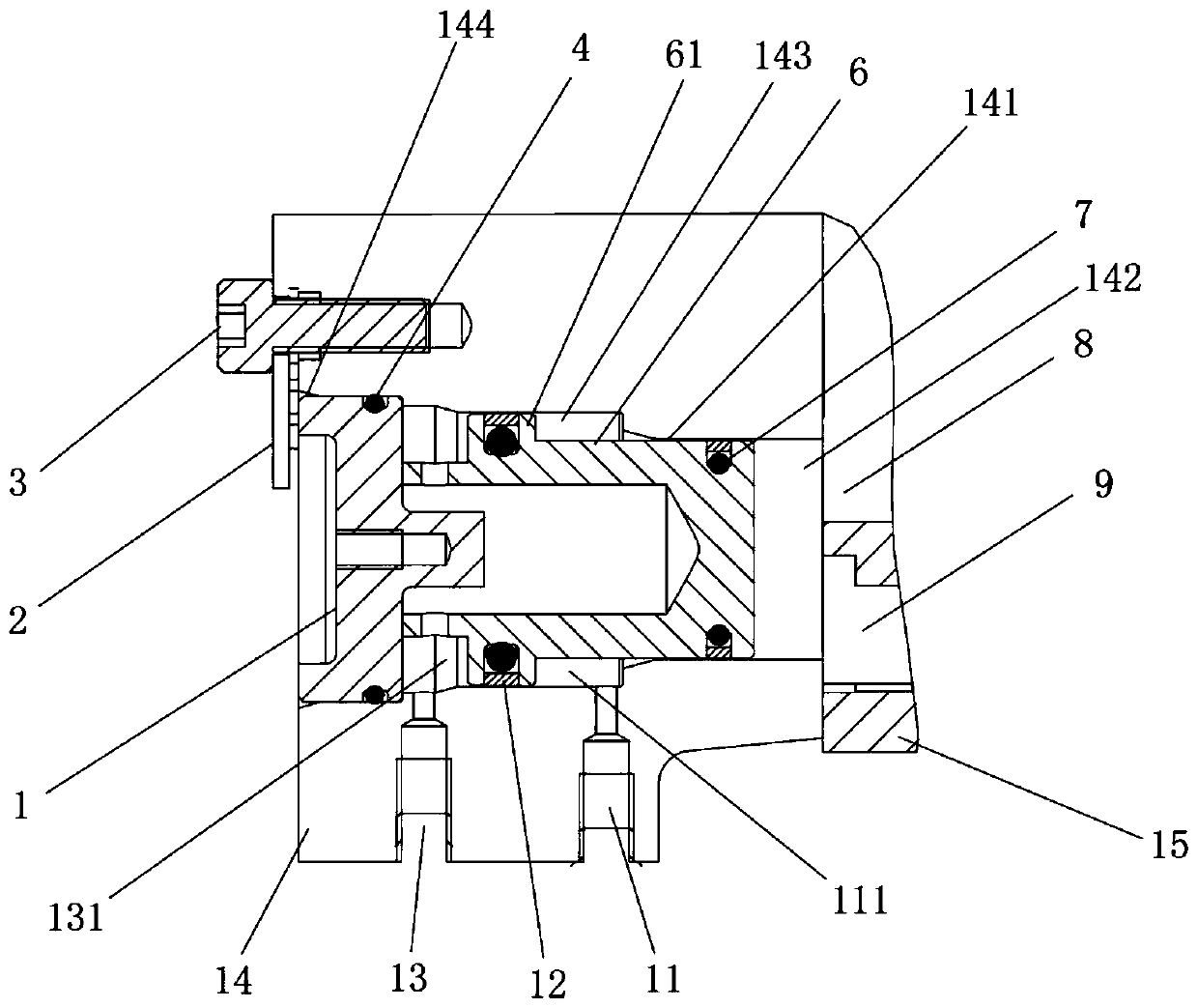

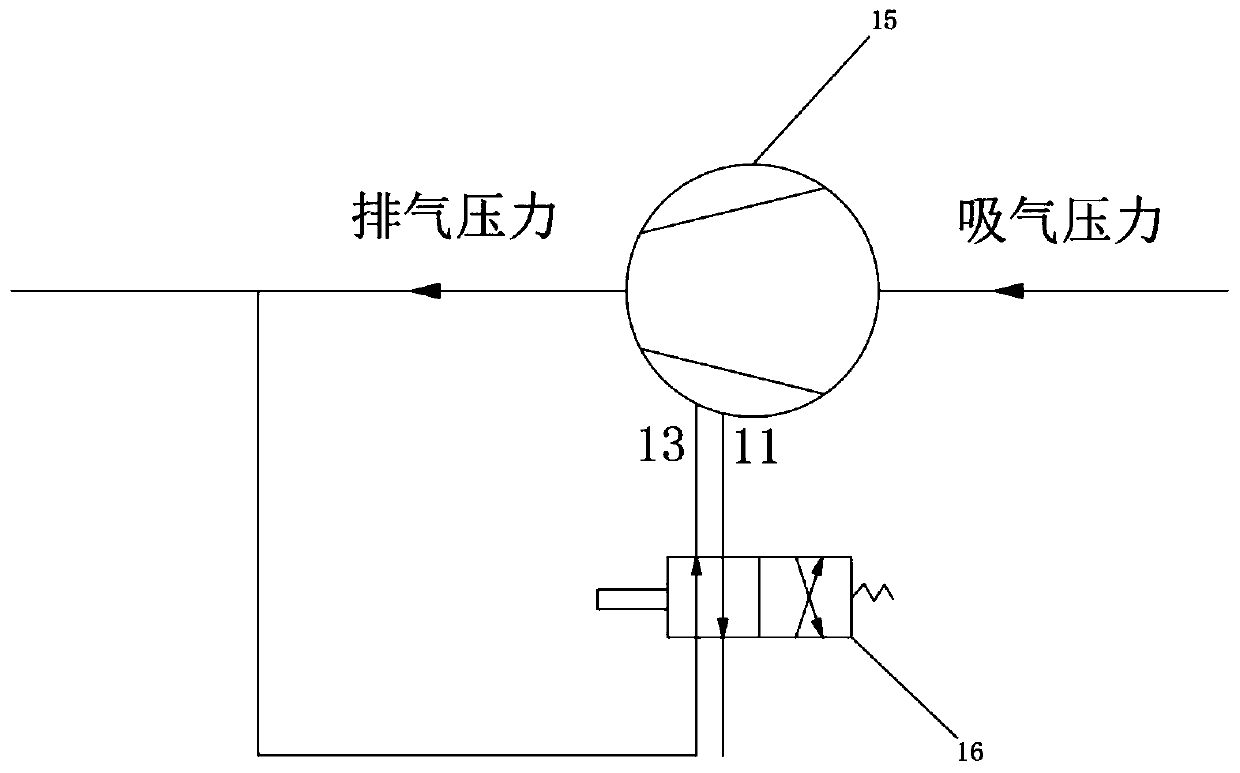

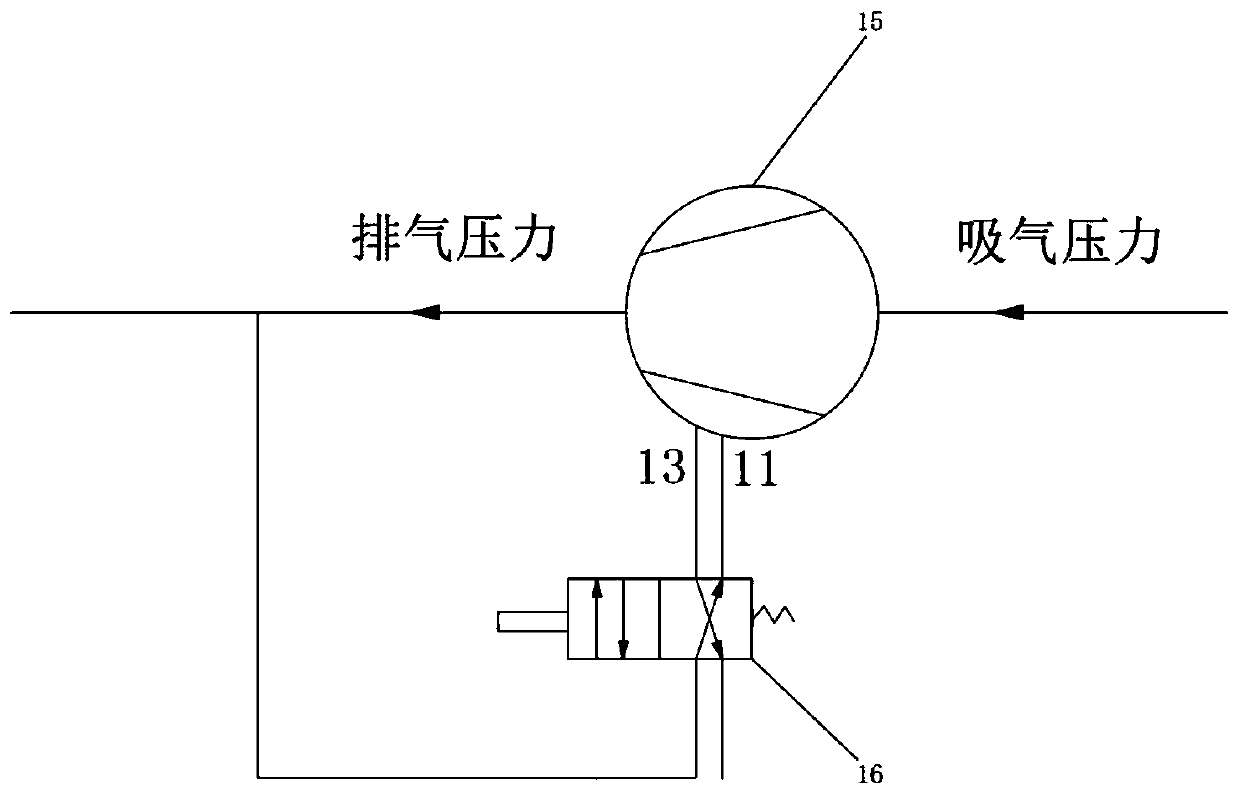

[0047] An automatic adjustment device for the built-in volume ratio of an air compressor for fuel cells, such as figure 1 , figure 2 , image 3 As shown, the exhaust housing 14 is provided on the air compressor; the air compressor is a screw compressor; and the exhaust housing 14 is provided with a mounting through hole 141, and the mounting through hole 141 connects the air compressor The exhaust cavity 8 on the rotor housing 15 is in communication with the bypass air cavity 9; the installation through hole 141 is provided with a capacity plunger 6, when the capacity plunger 6 is attached to the rotor housing 15, exhaust The cavity 8 and the bypass air cavity 9 are not connected. When the volume plunger 6 is separated from the rotor housing 15, the exhaust cavity 8 and the bypass air cavity 9 are connected; in order to ensure the sealing of the volume plunger 6 and the inner wall of the installation through hole 141 The outer wall of the displacement plunger 6 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com