Soil micro-plastics separating device and separating method

A separation device and technology for microplastics, which are applied in solid separation, preparation of samples for testing, etc., can solve the problems of not considering the surface adsorption of microplastics, tedious and time-consuming extraction of microplastics, and low recovery rate, and shorten the processing time. , save resources, increase the effect of separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

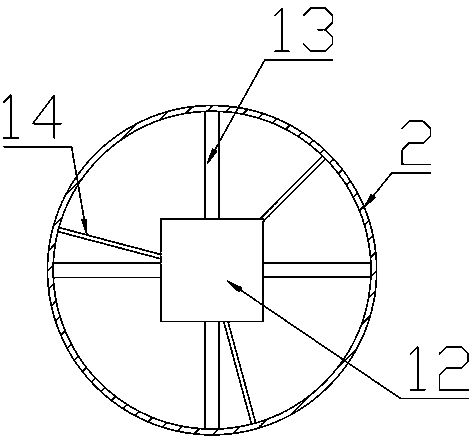

[0040] refer to Figure 1 ~ Figure 3 and Figure 7 , a microplastics separation device in soil, characterized in that it comprises a fixed box 5, a sample collection pool 2 and a vibrator 15, the fixed box 5 is provided with a conveying pipe 6, and the bottom of the conveying pipe 6 is provided with several A circular hole with a diameter of 2 cm is provided with a clip 16 matching the delivery pipe 6 below the circular hole. One end of the delivery pipe 6 passes through the fixed box 5 and is connected with an air pump 9, the air outlet end of the air pump 9 is provided with a gas flowmeter 8, and the other end of the delivery pipe 6 passes through the fixed box 5 and is connected with a filter 7, The fixed box 5 is opened along a side of the length direction of the conveying pipe 6, so as to observe the separation of microplastics in the soil. The filter 7 is trumpet-shaped, and the small-diameter end of the filter 7 is connected to the delivery pipe 6. The large-diameter ...

Embodiment 2

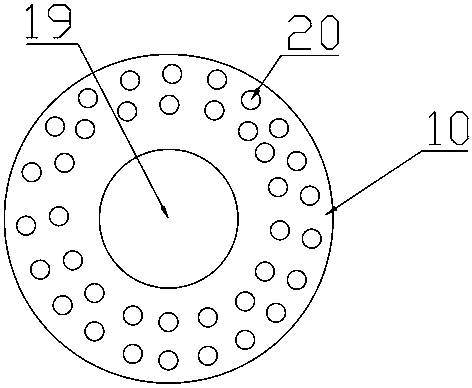

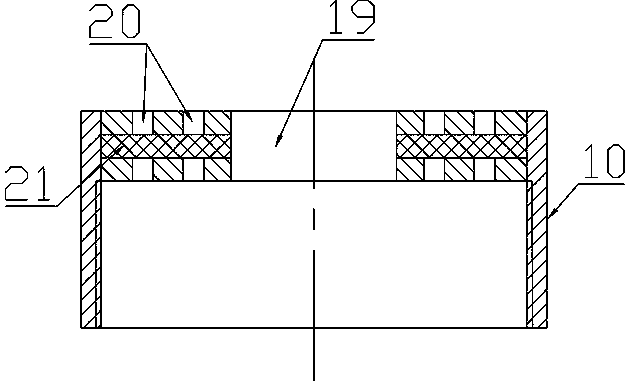

[0044] refer to Figure 4 ~ Figure 6 and Figure 7 , the present embodiment is basically the same as Embodiment 1, and the similarities will not be repeated. The difference is that: one end of the delivery pipe 6 is connected with an air pump 9, and the other end is connected with a sample collection bottle 11; A section of delivery tube 6 between the tube 23 and the sample collection bottle 11 is in the shape of an upward convex arc. A second support plate 22 is fixedly connected to the outside of the fixed box 5 , and the second support plate 22 is used to support the sample collection bottle 11 . The sample collection bottle 11 is threadedly connected with an air outlet cover 10, and a through hole 19 is arranged in the middle of the sealing portion of the air outlet cover 10, and the conveying pipe 6 passes through the through hole 19 and stretches into the sample collection bottle 11, and the sealing portion of the air outlet cover 10 It includes upper, middle and lower...

Embodiment 3

[0046] A method for separating microplastics in soil, comprising the steps of:

[0047] Step 1: Sampling: Collect soil from microplastic-polluted areas;

[0048] Step 2: Pretreatment: Air-dry the soil sample collected in step 1 after removing impurities to obtain a sample to be treated;

[0049] Step 3: preliminary selection: put the sample obtained in step 2 into the filter funnel 1, the sample falls into the vibrating plate 4 through the 5mm filter sieve on the filter funnel 1, and screen to obtain a soil sample with a particle size less than 5mm, turn on the vibrator 15, The vibrating plate 4 vibrates and drives the soil sample to vibrate. The microplastic particles with a lighter density in the soil sample gradually float on the soil surface with the vibration. Turn on the fan 3 and adjust the wind speed to blow the microplastics on the soil surface into the sample collection pool 2 middle;

[0050] Step 4: Check again: the microplastic particles separated into the sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com