A Method for Predicting the Stress-Strain Response and Strength of Braided Ceramic Matrix Composites

A composite material and prediction method technology, applied in the direction of instrumentation, design optimization/simulation, calculation, etc., can solve problems such as low process efficiency, large dispersion of measurement results, and difficulty in guaranteeing the accuracy of prediction results, so as to avoid prediction errors and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

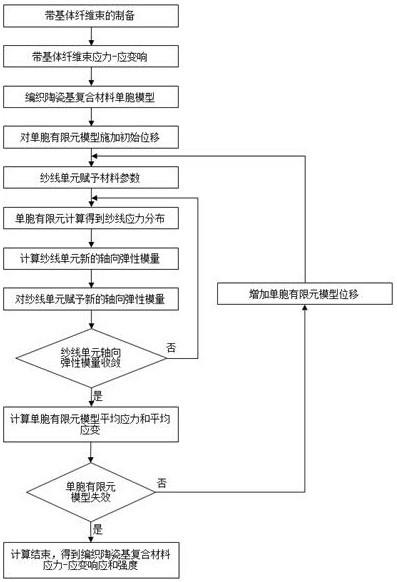

[0029] The invention will be described in detail below with reference to the accompanying drawings. Such as figure 1 As shown, the present invention provides a prediction method of stress-strain response and intensity of braided ceramic matrix composite material, which includes the following steps:

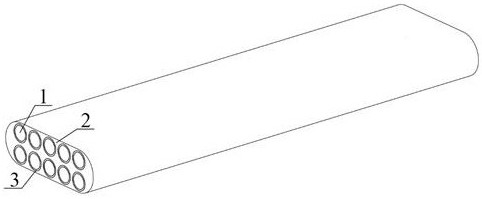

[0030] Step 1: A fiber bundle, the fibers and the woven ceramic matrix composite material are the same grade, and the fiber bundle is placed in the furnace to deposit the interface layer and the substrate together with the woven ceramic matrix composite. After deposition, the woven ceramic matrix composite preform is a braided ceramic matrix composite, and the fiber bundle is a band base fiber bundle. Such as figure 2 As shown, the belt of the base fiber bundle is composed of the interface layer 3 between the fibers 1, the base 2, and the fiber / matrix. Because of the formulating of the braided ceramic base composite, the base fiber bundle performance is clearly the same as the in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com