Automobile battery thermal management simulation method

A technology of automobile battery and simulation method, which is applied in secondary batteries, electrical digital data processing, circuits, etc., can solve the problems of inability to meet the early development cycle of battery pack internal structure layout, inability to obtain battery pack temperature distribution, and low analysis accuracy. , to achieve the effect of short simulation calculation time, easy acquisition and improved simulation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

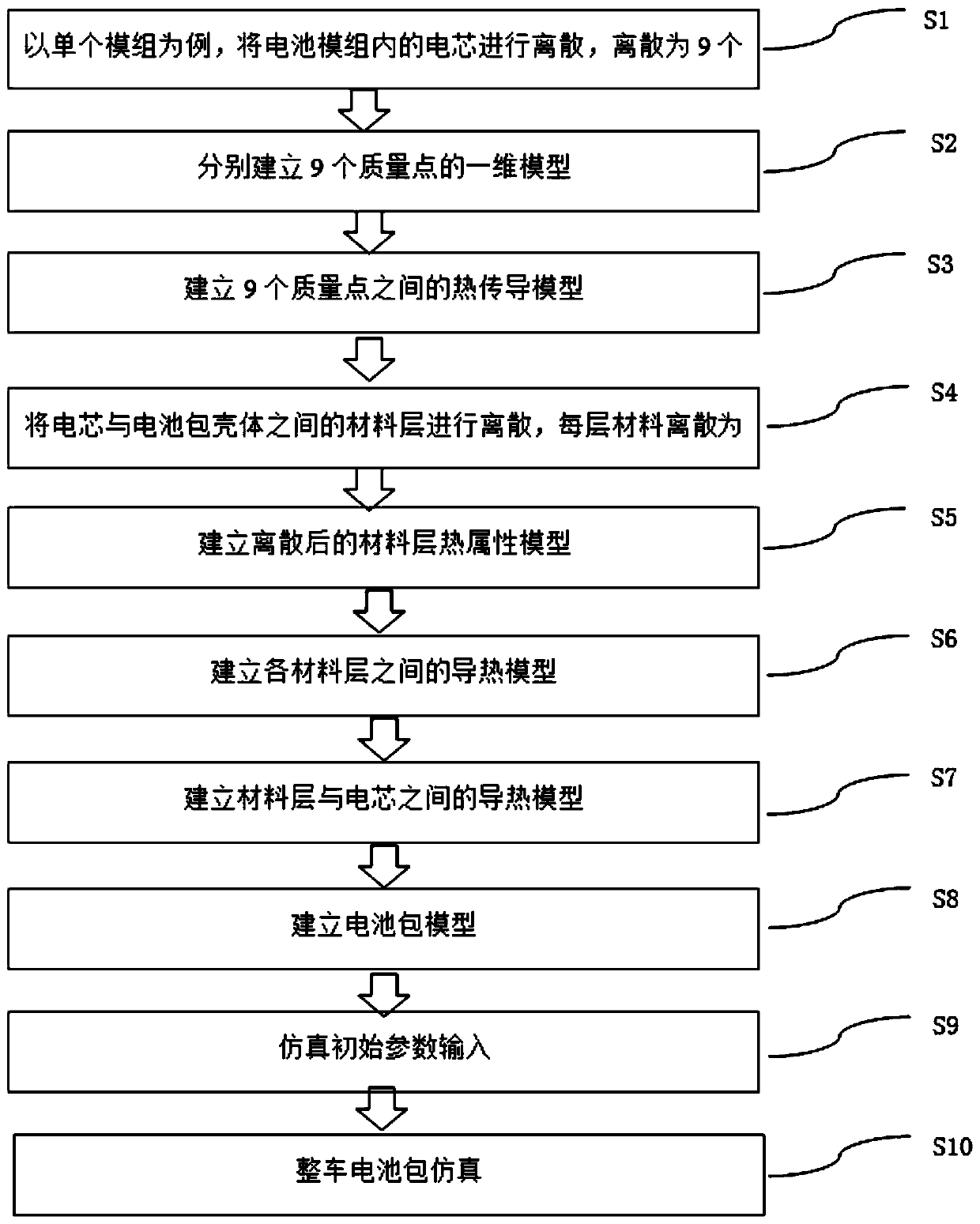

[0044] The present invention provides a thermal management simulation method for an automobile battery. Specifically, assuming that the battery pack contains 12 modules, and the battery cells in each module are arranged in the same manner, the method mainly includes the following steps:

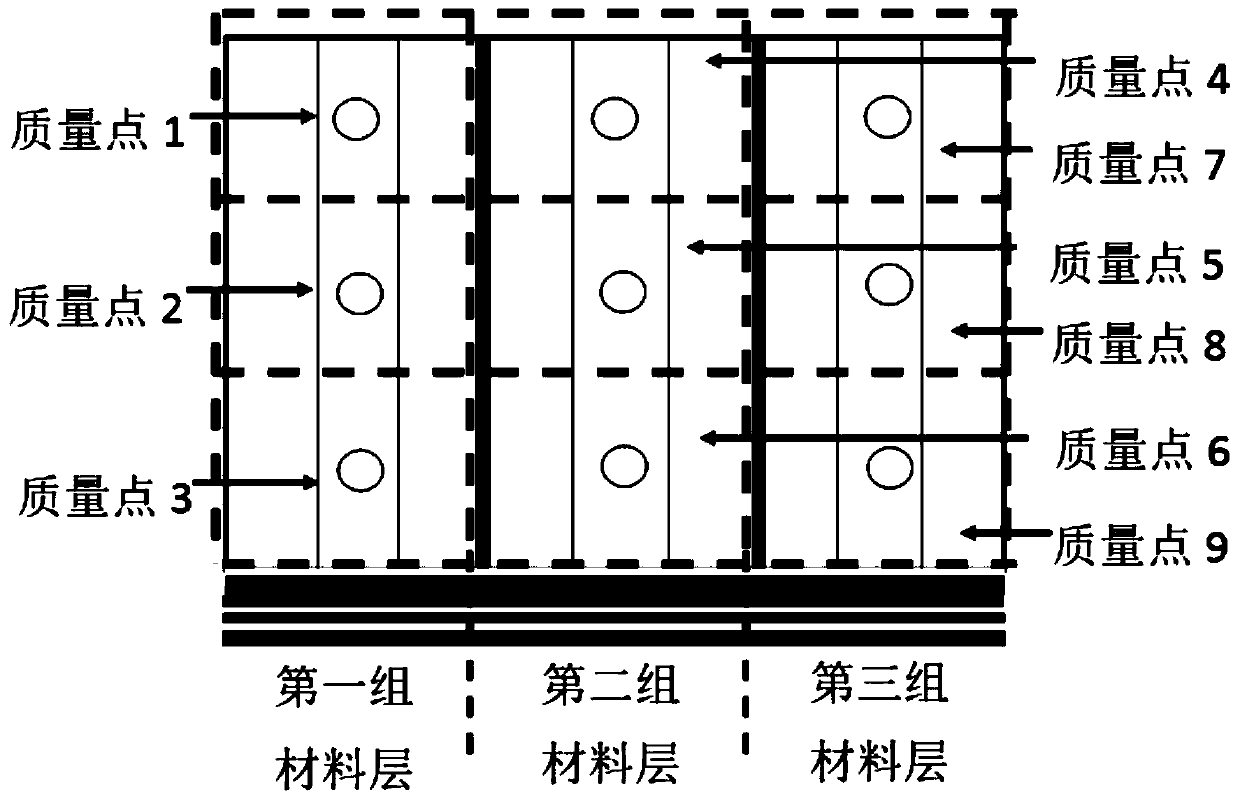

[0045] S1: Take a single module as an example, discretize the cells in the battery module into 9 mass points. Engineers can discretely divide the batteries in the module into any number according to actual needs, such as 3, 6, 8, 10 and so on.

[0046] S2: Establish the one-dimensional thermal property models of 9 mass points respectively.

[0047] S3: Establish a heat conduction model between 9 mass points.

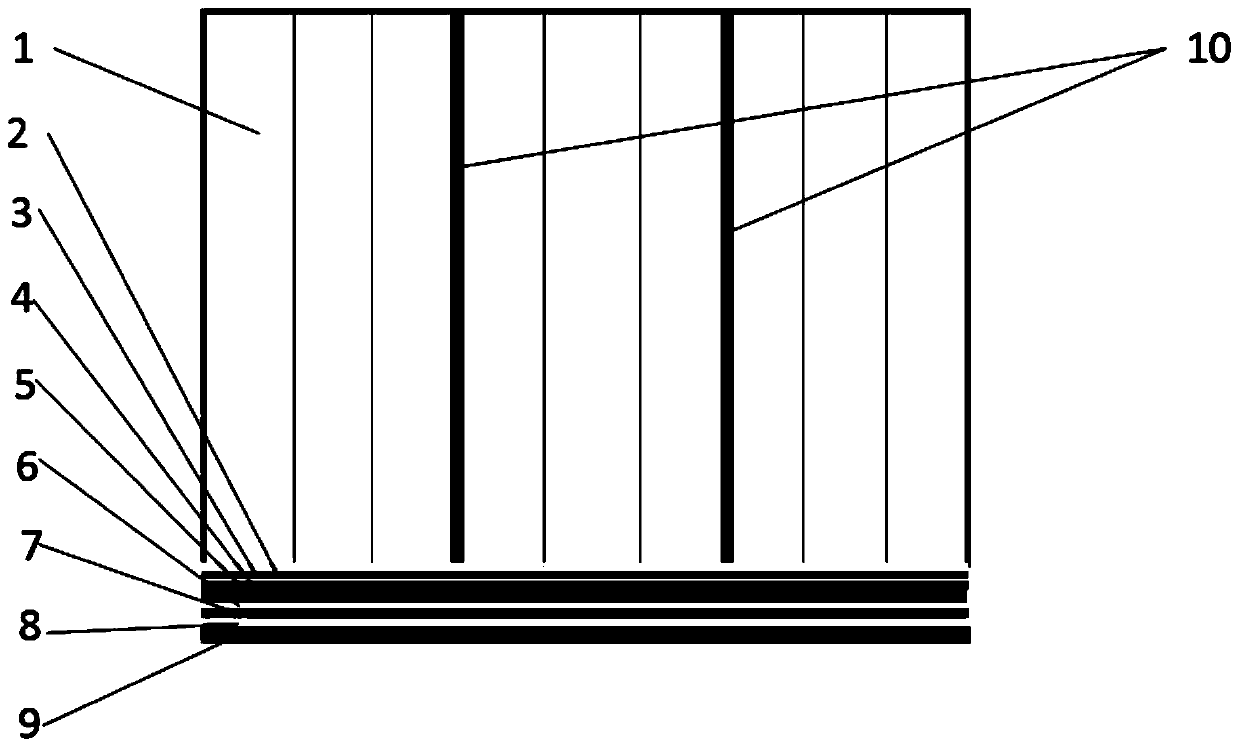

[0048] S4: Discrete the material layer between the battery cell and the battery pack case, and each layer of material is divided into 3 parts; the material layer that needs to be discrete here includes the heat conduction layer, the cooling water plate, the heat insulation layer, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com