Steel quality detection method based on interval shadow set and density peak clustering

A quality detection method and density peak technology, applied in character and pattern recognition, instruments, computer parts, etc., to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

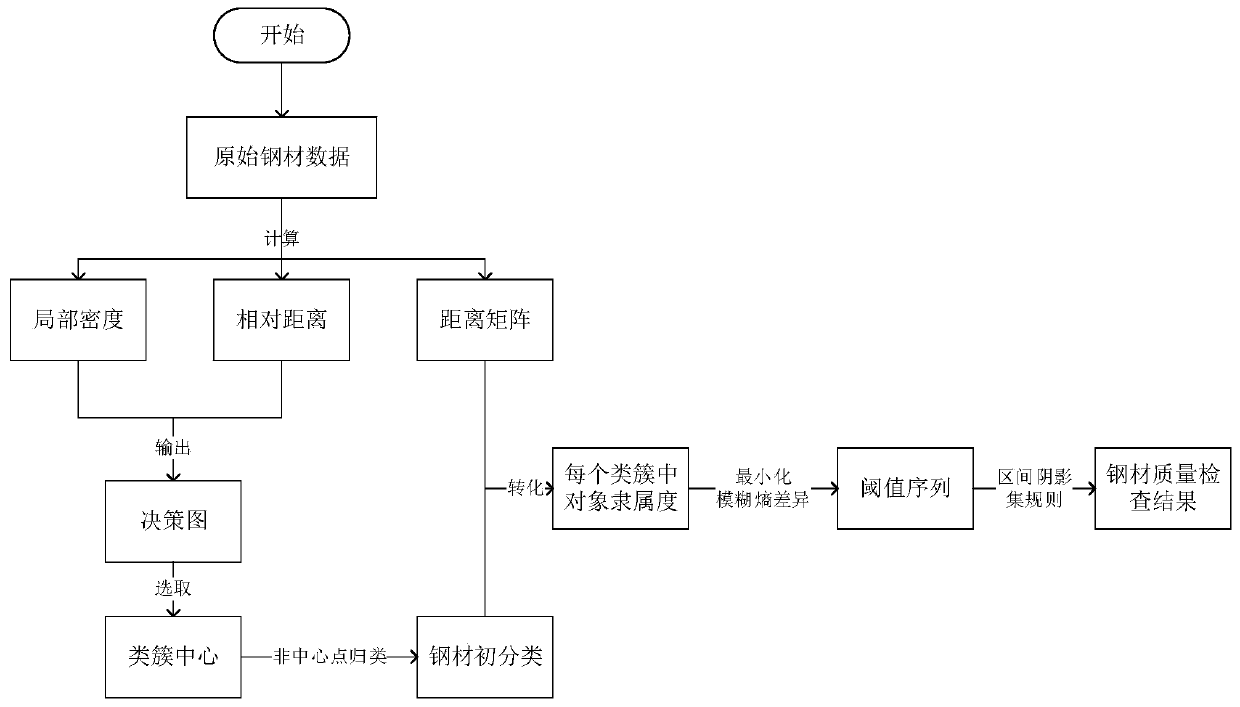

[0043] The present invention adopts a steel quality detection method based on interval shadow set and density peak clustering, and the following is abbreviated as ISS-DPC algorithm based on interval shadow set and density peak clustering; figure 2 As shown, the steel quality inspection method of the present invention includes the following steps:

[0044] Input: Data set S.

[0045] Output:

[0046] Step 1: Initialize parameter d c ;

[0047] Step 2: Calculate the local density ρ of each point by formula (1) or (2), and calculate the relative distance δ by formula (3);

[0048]

[0049]

[0050]

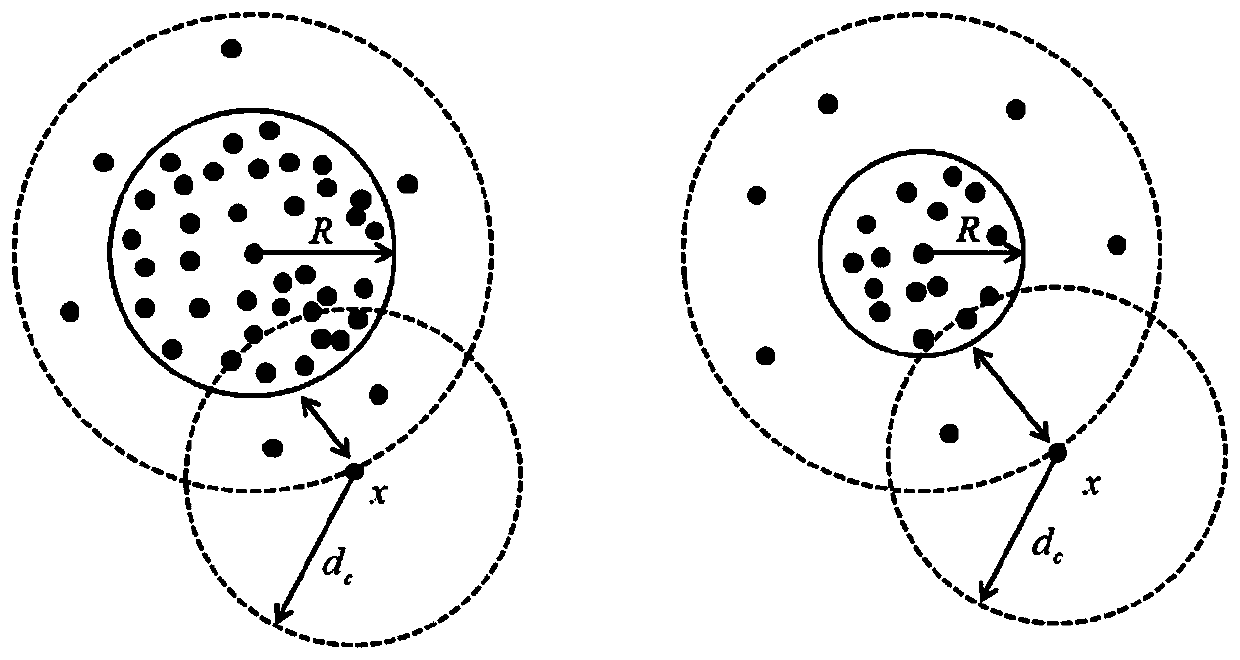

[0051] Where ρ i Represents the local density of the i-th object; δ i Indicates the relative distance of the i-th object; d ij Means x i With x j Distance between, parameter d c Is the cutoff distance; x i Represents the i-th object in the steel data set S; S={x 1 ,x 2 ,...,X n }; n represents the total number of objects in the steel data set; I S Represents the object index set, I S ={k∈I ...

Embodiment 2

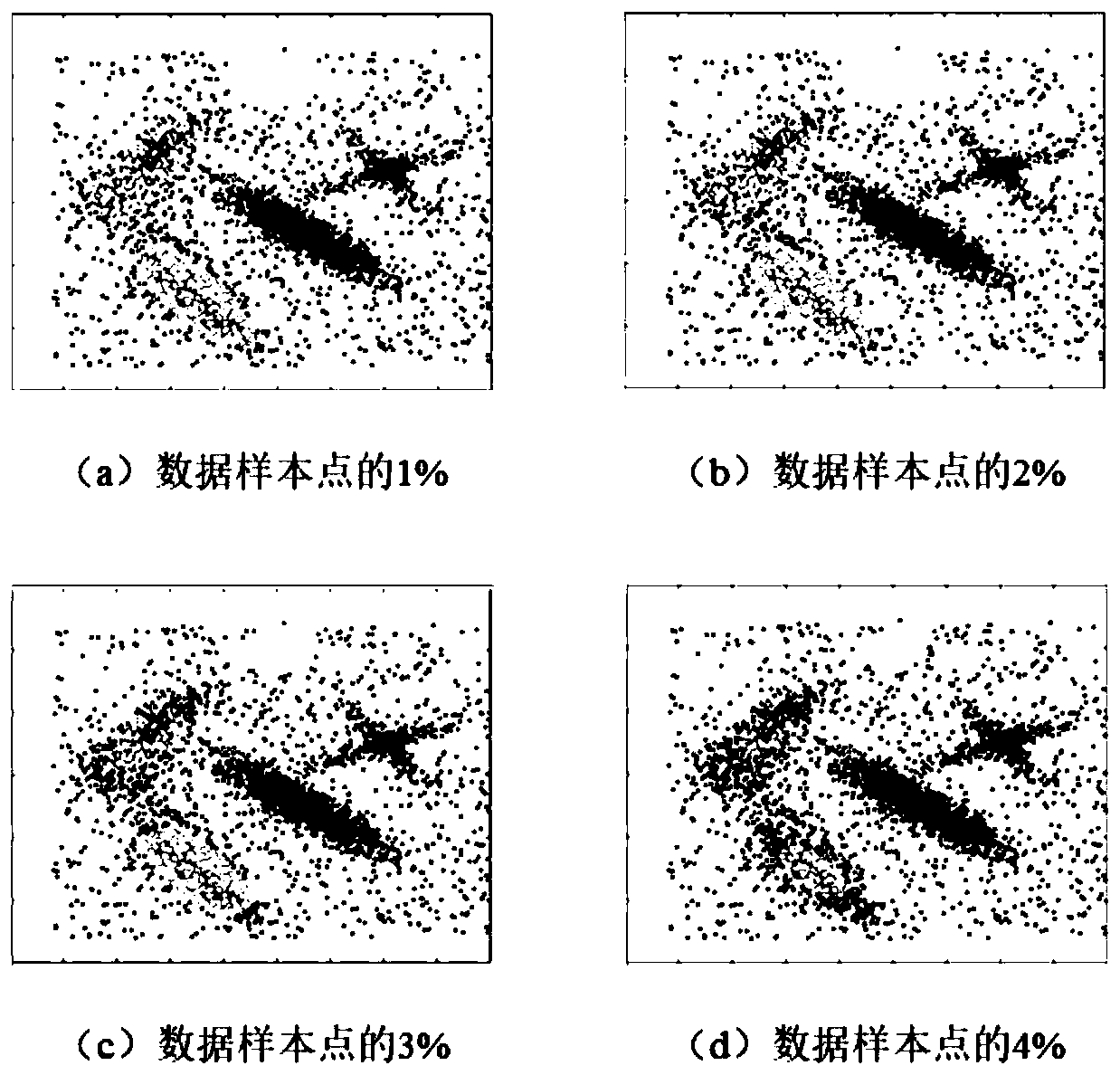

[0094] This example takes the steelmaking data of a steel plant as an example. For the convenience of presentation and explanation of the problem, the present invention selects two columns of data as an example for cluster analysis. The selected two columns of data are the target end temperature in the furnace and the molten steel temperature, total 800 pieces of data. As shown in Table 1, the first 10 data in the original table are listed:

[0095] Table 1 Part of the original data

[0096]

[0097] In the original data table, each row of data records related indicators in the steelmaking process. When the target end temperature in the furnace differs from the molten steel temperature, the higher the quality of the steel produced; on the contrary, the greater the difference, the lower the quality of the steel. Therefore, this example uses cluster analysis to quickly determine the quality of steel.

[0098] Table 2 lists the distance matrix of the first 10 data in the original tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com