Vibration power generation device of automobile

A technology for vibration power generation and automobiles, applied in the field of vehicles, can solve the problems of shortening the service life of the battery, damage to the battery, and small electric energy, and achieve the effect of prolonging the service life and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings.

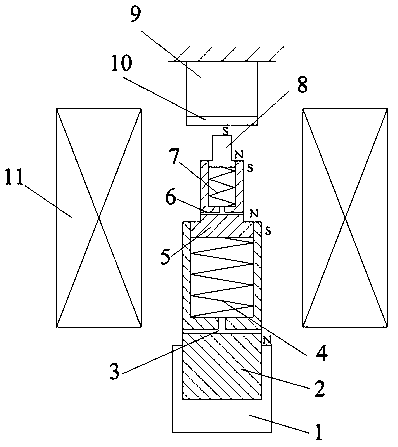

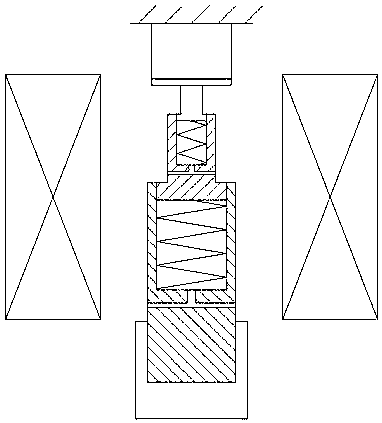

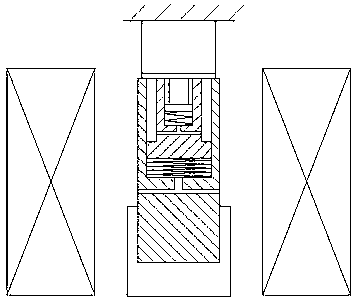

[0039] A vibration power generation device for a car, as attached figure 1 As shown, it includes a hollow induction coil mechanism 11 and a permanent magnet telescopic mechanism fixedly connected with the shock absorber 1 of the automobile. The permanent magnet telescopic mechanism can move back and forth in the direction of the central axis of the induction coil mechanism 11. Arranged along the direction of the central axis of the induction coil mechanism 11, a plurality of permanent magnets are arranged on the permanent magnet expansion mechanism, and the plurality of permanent magnets can move away from or approach each other when the permanent magnet expansion mechanism stretches, thereby generating different magnetic fields. The fixed end is used to be connected with the shock absorber 1 of the automobile, and the limit stopper 9 that can be contacted w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com