Ball valve machining method

A processing method and ball valve technology, applied in the field of mechanical processing, can solve the problems of high production cost, low production efficiency, inability to meet the user's demand for mass product delivery, etc., to reduce production costs, efficient operation, and reduce inner hole finishing. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

[0022] This embodiment takes the machining of a cemented carbide ball valve as an example to give a detailed explanation of the method for machining the outer circle and inner hole of a cemented carbide ball valve provided by the present invention.

[0023] In this embodiment, the process dimensions of the cemented carbide ball valve with the inner hole and the outer circle are as follows: the outer circle size of the cemented carbide ball valve is required to be SΦ45+(0~0.02)mm, the roughness is Ra0.025, and the inner hole size is required to be Φ25+(0 ~0.2) mm.

[0024] The method for processing the above-mentioned cemented carbide ball valve provided in this embodiment includes the following steps:

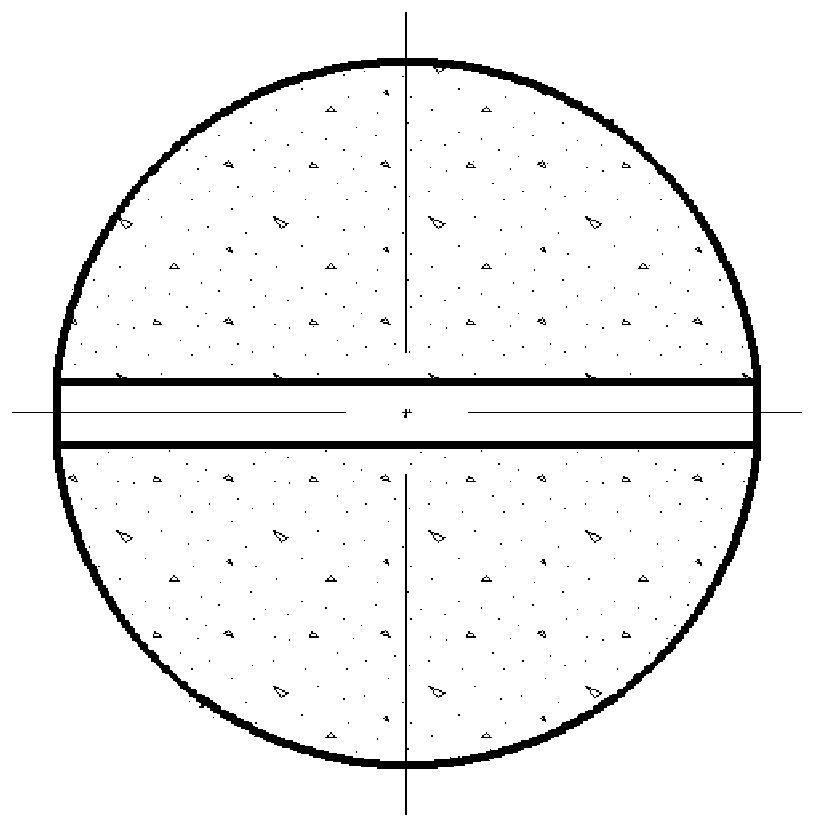

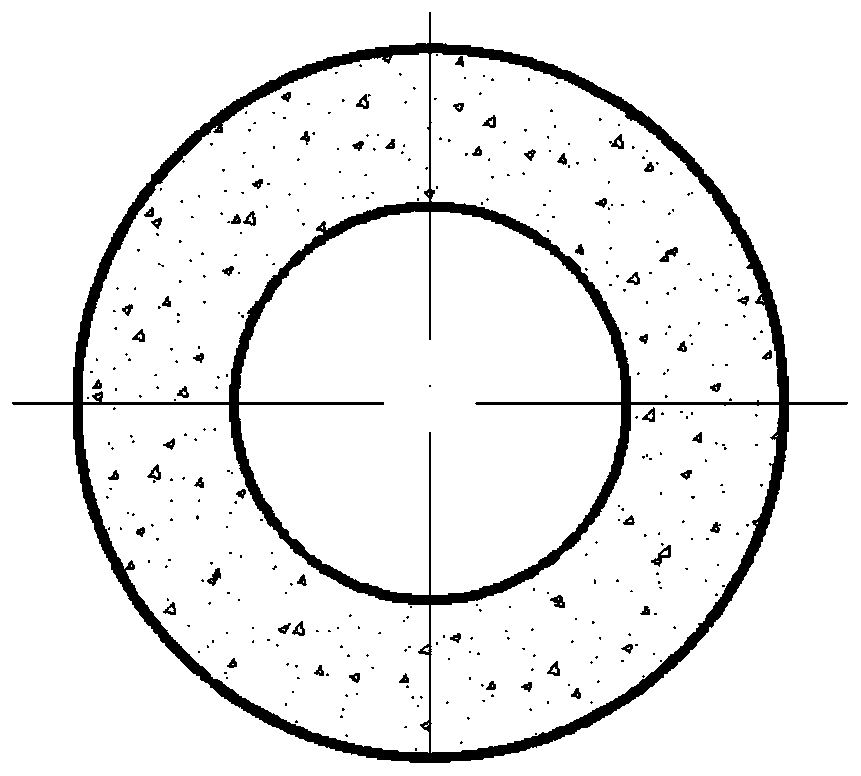

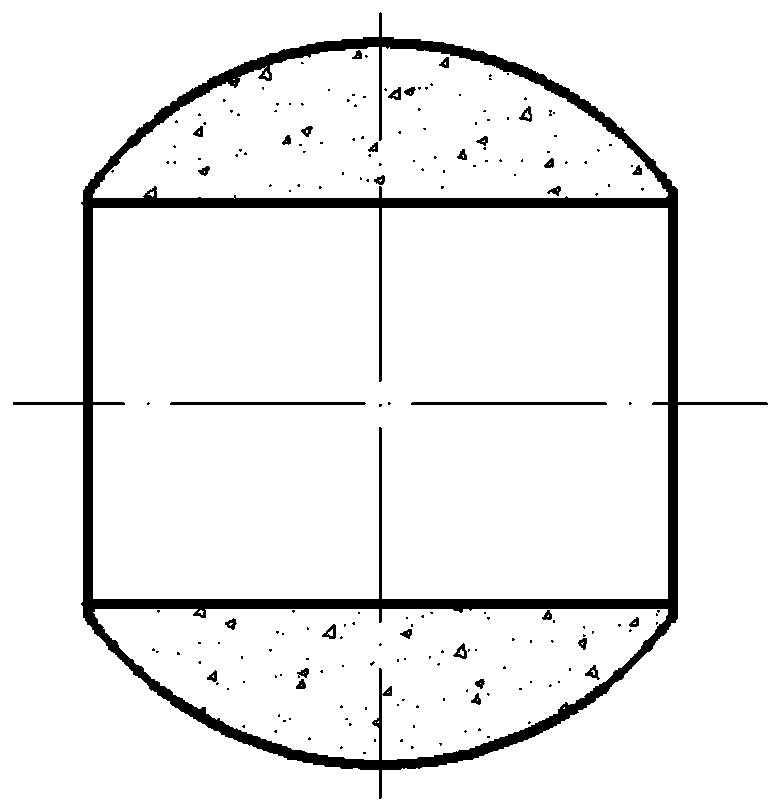

[0025] (1), the production of carbide ball valve blanks with inner holes such as figure 2 , 3 As shown, there is a machining allowance in the design size of the inner ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com