Flexible epoxy glue and preparation method thereof

An epoxy adhesive and flexible technology, which is applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of affecting the use and operation, and the performance degradation of epoxy cured products, so as to increase flexibility and elongation at break The effect of lifting and improving the temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

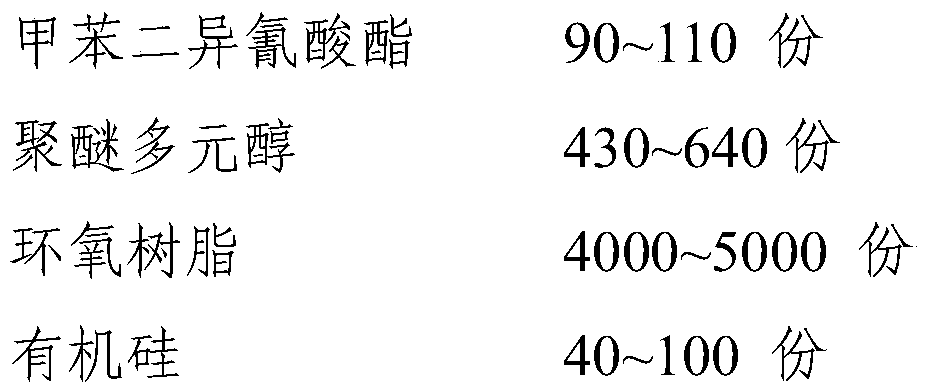

[0054] This embodiment provides a flexible epoxy glue, the flexible epoxy glue is composed of A component and B component; by mass parts, the formula of the A component is as follows:

[0055]

[0056] The formula of the B component is as follows:

[0057]

[0058]

Embodiment 2

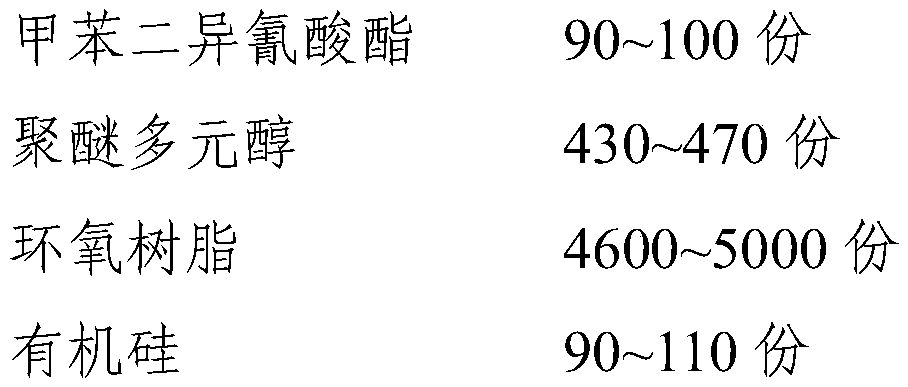

[0060] This embodiment provides a flexible epoxy glue, the flexible epoxy glue is composed of A component and B component; by mass parts, the formula of the A component is as follows:

[0061]

[0062] The formula of the B component is as follows:

[0063]

Embodiment 3

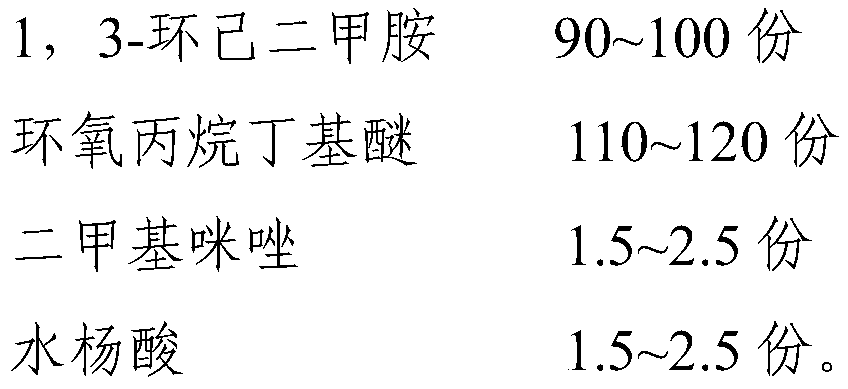

[0065] This embodiment provides a flexible epoxy glue, the flexible epoxy glue is composed of A component and B component; by mass parts, the formula of the A component is as follows:

[0066]

[0067] The formula of the B component is as follows:

[0068]

[0069]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com