Cathode roller side plate anti-crystallization device, crude foil machine and anti-crystallization method

A cathode roller, anti-crystallization technology, applied in the electrolysis process, electroforming and other directions, can solve the problems of process fluctuation, dilution of copper acid concentration in electrolyte, etc., and achieve the effect of avoiding crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

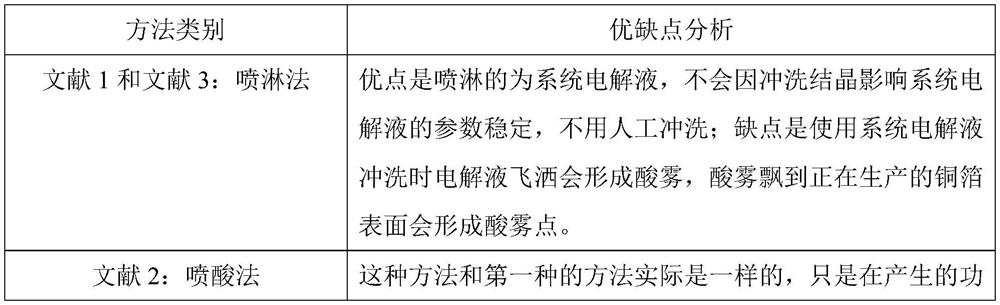

[0054] From the document 1 mentioned in the background technology, it can be seen that:

[0055] Rinsing the cathode roll with pure water will cause the pure water of the electrolyte system to enter the system, which will affect the stability of the solution parameters (the method recorded in the background technology of Document 1);

[0056] In order to avoid the above-mentioned problems, a method of rinsing the sides of the cathode roll with an electrolytic solution has been proposed. The disadvantage of using systematic electrolyte to flush the side of the cathode roller to prevent crystallization is that it will form acid mist, which will easily float to the surface of the copper foil to form acid mist spots (small black spots), especially for the cathode roller of 1.5 meters, because of the height Not enough, the acid mist easily drifted to the foil surface.

[0057] To this end, it is necessary to break the technical bias of documents 1, 2, 3, and 4.

[0058] First, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com