Rubber-mixed magnetic powder and preparation method thereof

A technology of magnetic powder and rubber mixing, which is applied in the manufacture of inductors/transformers/magnets, magnetic materials, magnetic objects, etc., and can solve problems such as low magnet density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Another aspect of the present application provides a method for preparing the above rubber-mixed magnetic powder, the preparation method comprising: performing a first mixing process on the first magnetic powder, a binder and a curing agent to obtain a first intermediate product; The intermediate product and the second magnetic powder are subjected to a second mixing process to obtain a rubber-mixed magnetic powder, and the amount and particle size of the first magnetic powder are larger than those of the second magnetic powder.

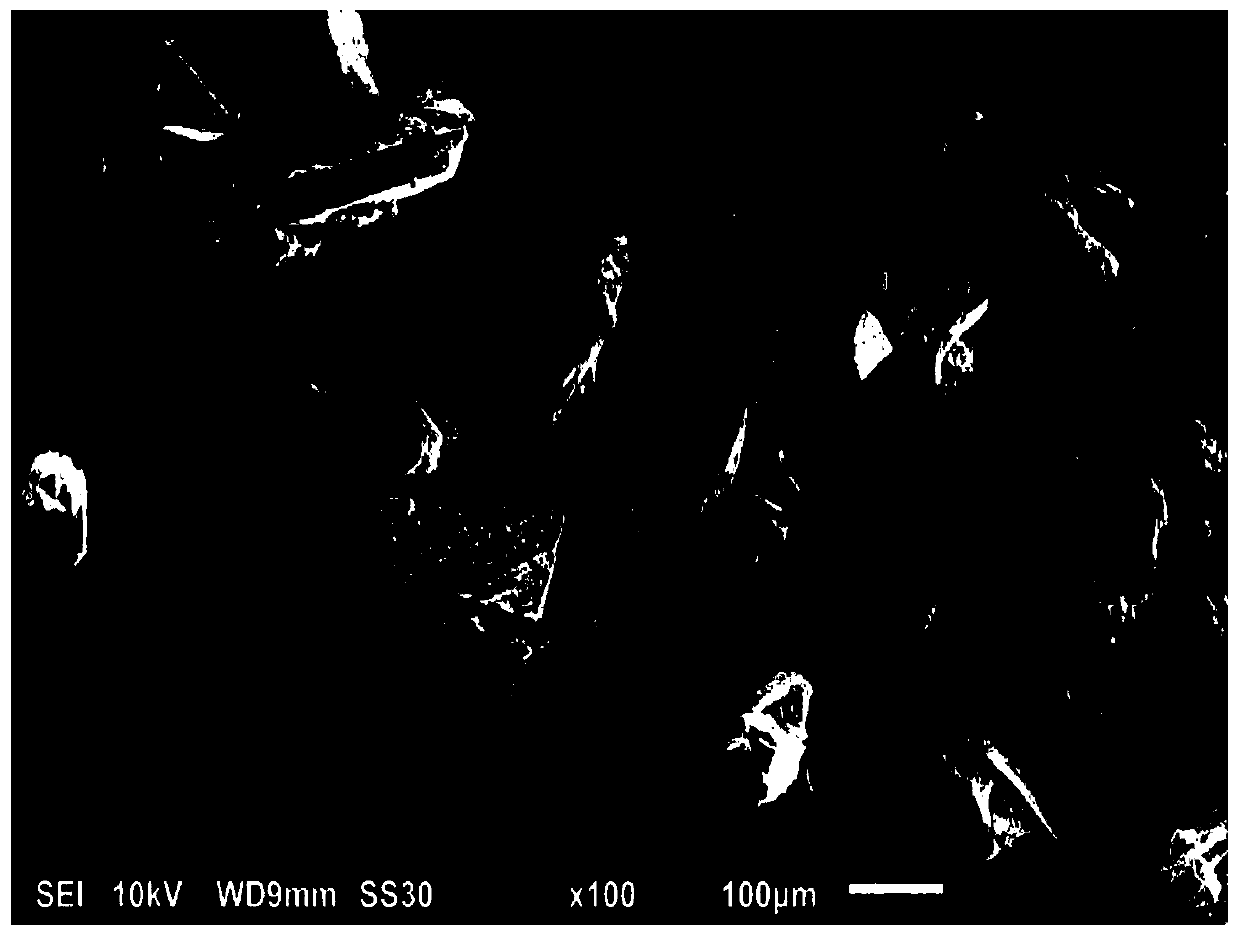

[0035]In the above rubber-mixed magnetic powder provided by this application, since the amount and particle size of the first magnetic powder are larger than that of the second magnetic powder, during the mixing process, under the action of the binder, the second magnetic powder will be coated on the first magnetic powder or the second magnetic powder. The surface of agglomerates formed by magnetic powder. This enables the second magnetic powd...

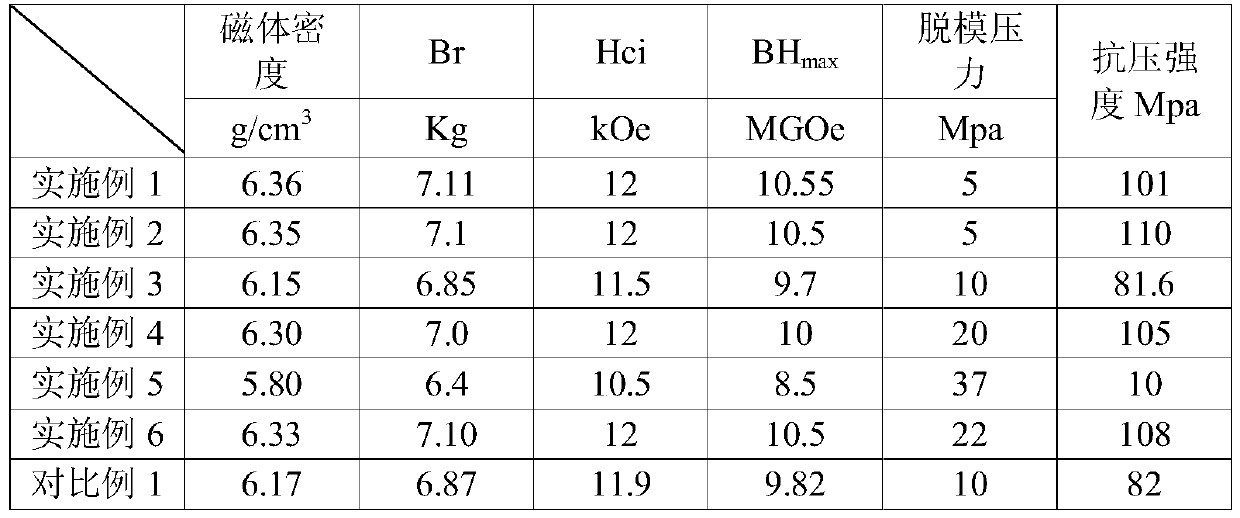

Embodiment 1

[0039] 13.264g solid epoxy resin NPES-302 and 5.306g liquid epoxy resin Epon828 and 0.557g dicyandiamide curing agent are dissolved in acetone solution to obtain a mixed solution; drop into the first 884.266g magnetic powder (MQP- 14-12, 198μm), after stirring evenly, heat at 65°C, and condense under vacuum conditions, so that acetone can be volatilized and recovered to obtain the first magnetic powder agglomerate, the weight ratio of solid epoxy resin to liquid epoxy resin It is 2.5:1.

[0040] The above-mentioned first magnetic powder agglomerates and 95.556 g of the second magnetic powder (MQFP, 5 μm) were uniformly mixed to prepare fluid mixed rubber powder particles. After passing the above-mentioned mixed rubber powder particles through a 60-mesh (250 μm) sieve, and 1.051 g of zinc stearate (lubricant), the mixed rubber magnetic powder that can be used directly is formed, wherein the weight ratio of the first magnetic powder and the second magnetic powder is It is 9.25:...

Embodiment 2

[0047] Dissolve 16.882g of solid epoxy resin NPES-302 and 1.688g of liquid 1H,1H,2H,2H-perfluoroheptadecanetrimethyloxysilane and 0.557g of dicyandiamide curing agent in an acetone solution to obtain a mixed solution; Put 884.266g of the first magnetic powder (MQP-14-12, 198μm) into the above mixed solution, stir evenly, heat at 60°C, and condense under vacuum conditions to make the acetone volatilize and recover, and obtain the first magnetic powder agglomeration The weight ratio of solid epoxy resin to liquid binder is 10:1.

[0048] The above-mentioned first magnetic powder agglomerates and 95.556 g of the second magnetic powder (MQFP, 5 μm) were uniformly mixed to prepare fluid rubber-mixed magnetic powder particles. After passing the above-mentioned mixed rubber powder particles through a 60-mesh (250 μm) sieve, and 1.051 g of zinc stearate (lubricant), the mixed rubber magnetic powder that can be used directly is formed, wherein the weight ratio of the first magnetic pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com